List of documents for assembly

The following is the list of documents required for the PCB assembly process:

- Assembly drawing

- Assembly notes

- Schematic diagram

- Bill of materials (BOM)

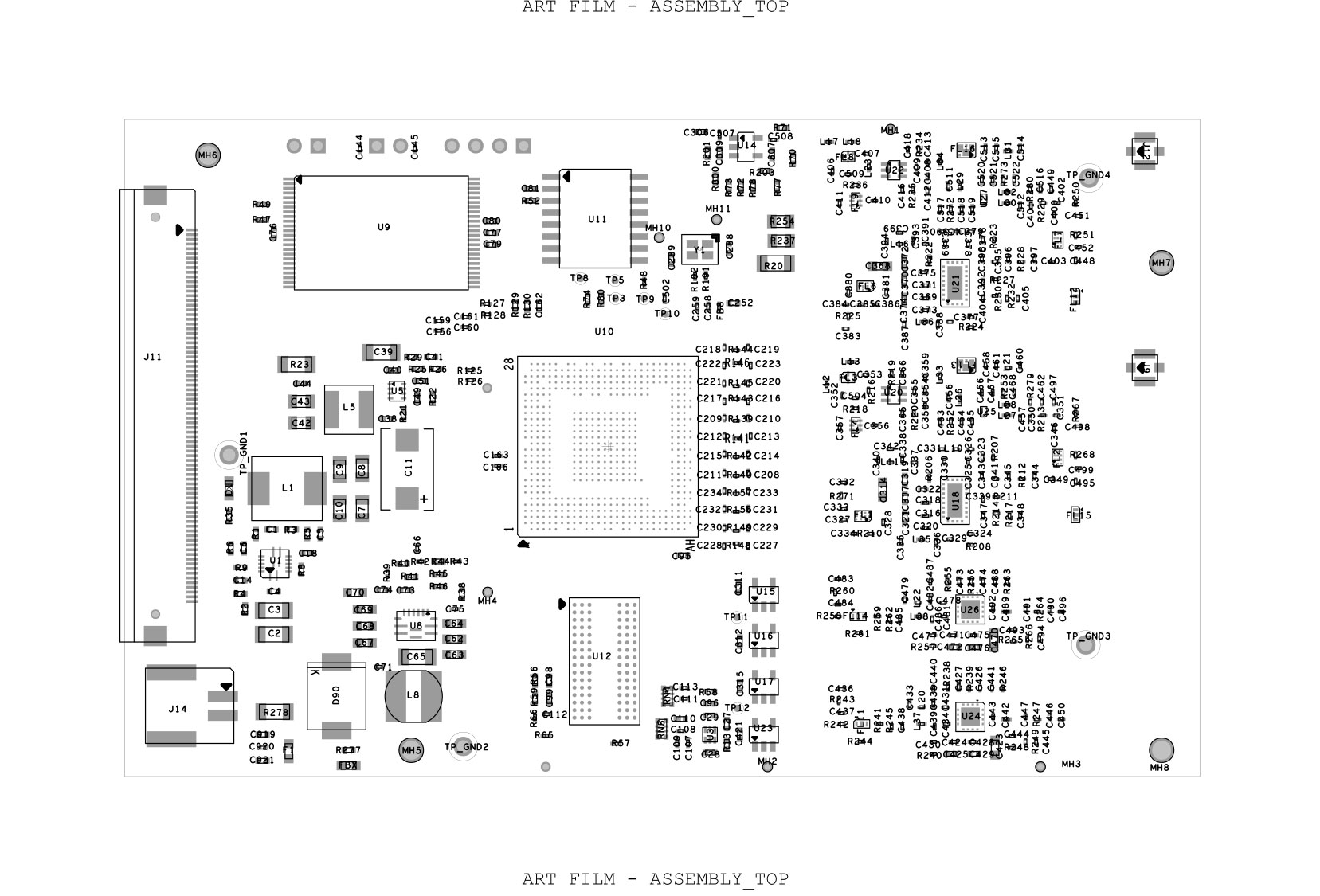

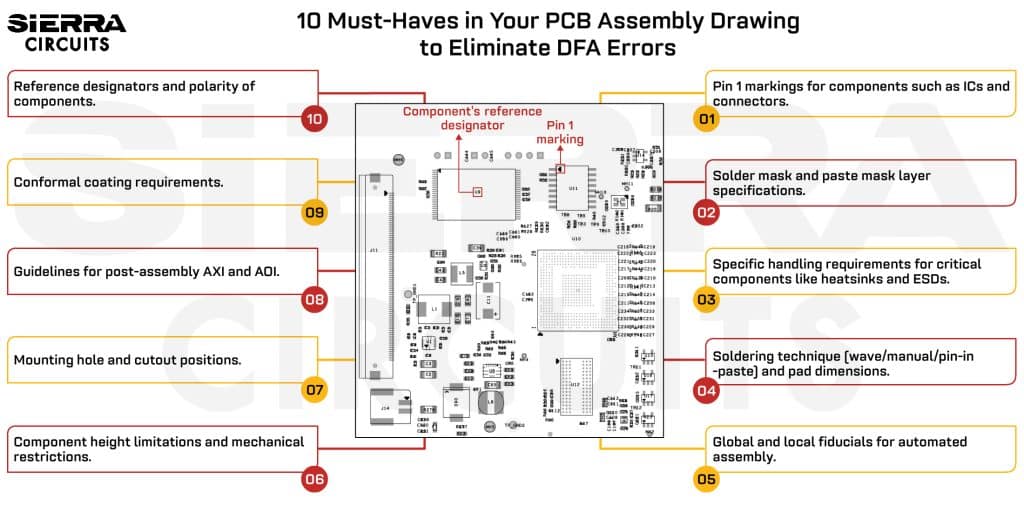

Assembly drawing

An assembly drawing displays all the components on the board in their assembled locations, along with their corresponding reference designators for identification.

Here’s what you need to include in your assembly drawing to avoid DFA errors and ensure seamless prototype production.

Design for Assembly Handbook

6 Chapters - 50 Pages - 70 Minute ReadWhat's Inside:

- Recommended layout for components

- Common PCB assembly defects

- Factors that impact the cost of the PCB assembly, including:

- Component packages

- Board assembly volumes

Download Now

What are PCB assembly notes?

Assembly notes are instructions provided by board designers to help the CM assemble the board by placing components following a specific order and procedure.

It is up to the designer to adapt modifiers in the notes according to the requirement.

What are the benefits of assembly notes?

Assembly notes are essential in the manufacture of PCBs and serve the following functions:

Designate the primary side of the board

All circuit boards have their sides designated as the primary (top side) and the secondary side (bottom side) based on the design needs. Just as indicated in the board fabrication drawing, the primary side designation should be reflected in the PCB assembly drawing as well. The assembly pictorial representation should portray the primary side of the board as the top view in the drawing. In cases where components are present on both sides (primary and secondary), an additional view displaying the secondary side should be added to the layout.

Define reference designators

Reference designators are typically printed onto the board. Although, stakeholders might sometimes miss the printed reference alphanumeric markings on the PCB. In some cases, there might not be sufficient space to print some or all assembly markings. In such scenarios, the board assembly notes allow adequate space for all the required assembly markings to be displayed.

A good assembly drawing has the unique advantage of scalability which enables designers to show component designators adequately. Such designators should be legible and placed within the component outline to offer guidance to assembly, inspection, and field service personnel.

Example: Components are identified by checking the reference designators in the bill of materials against those on the face of the drawing. Reference designators are used for reference purposes only and may not appear on the board or part.

Describe mounting instructions

IPC-CM-770 guidelines for printed circuit board component mounting specify effective methods of component mounting. When this specification is included in the assembly drawing, it can serve as a communication channel between customers and manufacturers, or designers and fabricators.

In addition to this, IPC-A-610 is included as a manufacturing acceptance specification, defining the acceptance standard for every assembly operation. This will hold good regardless of the assembly method used.

For boards having manually mounted components, the assembly drawings will also mention the height restrictions of the components. In some cases, clearances from other components will also be mentioned.

Example:

- PCB component mounting shall conform to IPC-CM-770.

- Acceptability of this electronic assembly shall conform to IPC-A-610 class 2.

Specify soldering instructions

J-STD-001 is the joint global industry standard for electrical and electronics assembly soldering. It details the materials, techniques, and verification needs for all features for creating high-quality solder joints. The standard of solderability tests is given by the J-STD-003 specification which includes definitions of defects along with their diagrams. These two specifications can be used together in an assembly note to verify the quality of interconnections.

Example: Solder per J-STD-001 and J-STD-003.

Note all the specialized assembly methods

Most board documentation will need specialized assembly methods that are lead-free. The exception to this assumption is PCBs used for military and space applications. Such environmental specifications and lead-free assembly requirements are documented in the bill of materials. The specialized marking methods that are needed for these particular assemblies are defined in the IPC-1066 standard.

IPC-1066 is however not applicable if:

- Lead is used as an alloying element in these metals with the alloying percentages given:

- Steel – 0.35%

- Aluminum – 0.4%

- Copper – 0.4%

- Lead present in electronic ceramic parts in piezoelectric devices

Use of IPC-1066in PCB assembly notes: The assembly shall satisfy environmental requirements in the bill of materials. Mark the assembly with solder material categories used in line with the IPC-1066.

IPC-A-610 standard for assembly: Acceptability and qualifications

Manufacturers refer to the IPC-A-610 standard for PCBA acceptability. This will define the comprehensive requirements for a board assembly ranging from component mounting (THT and SMT), soldering specifications, handling considerations, markings, solder mask specifications, etc.

The IPC-A-610 standard is further divided into three classes:

- Class 1: This is for products that do not require strict adherence to the IPC guidelines and are used for the manufacture of non-critical board assemblies such as the ones used in toys.

- Class 2: This class is designated for products that are not critical yet require a level of reliability in their operation.

- Class 3: Here the products manufactured need to adhere strictly to all the IPC guidelines for assembly including ones for aesthetics apart from electrical and mechanical properties.

Schematic diagram

A PCB schematic is a simple two-dimensional circuit design displaying the functionality and connectivity between various components in the circuit. The schematic is the first step toward designing a board that involves a pictorial representation of the circuit using standard or customized symbols to detail circuit connections.

Please note that we offer flying probe testing after assembling the board. Including the schematic will help us debug any kind of issues in it. ODB++ or IPC 2581 files are sufficient for FPT, but a schematic will allow for proper debugging.

Bill of materials

A bill of materials is a comprehensive list of the components and materials that are required to assemble a circuit board. It will hold all the required information on every part that is assembled onto the board. This information will include:

- Item

- Quantity

- Part description/value

- Reference designator of components

- DNI(do not install)/DNP(do not populate): This field indicates whether the components should be populated or not to be populated.

- Manufacturer name

- Manufacturer part number (MPN)

- Vendor name

- Vendor part number (VPN)

- Footprint type

- Alternate part number (optional)

Precise PCB assembly notes in an assembly drawing ease the entire assembly process. Basically, you will be helping your manufacturer to efficiently assemble your PCBs according to your requirements.

See our FAQ on PCB assembly for more information.