What is a rigid-flex PCB?

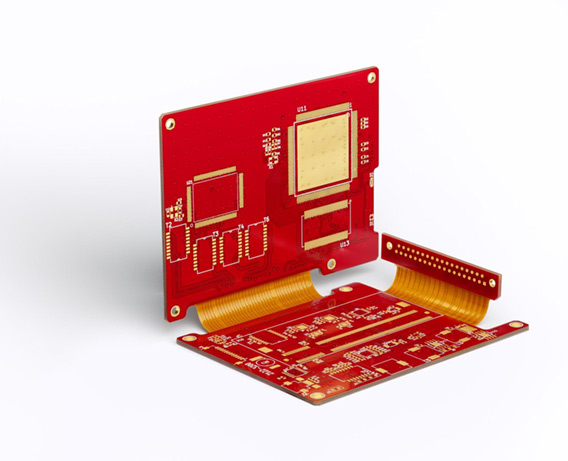

Rigid-flex boards are hybrid PCBs that combine the characteristics of rigid and flexible materials. The design of these circuit boards may include multiple conductive layers in the rigid and flexible sections.

Also, see rigid PCB assembly for traditional FR4 board manufacturing and flex PCB assembly for fully bendable circuit applications.

Rigid-flex PCB assembly

During rigid-flex assembly, components will be mounted on both the rigid and flex regions. A rigidized flex circuit is nothing but a flex PCB with an FR4 stiffener added to strengthen the rigidity during assembly. The layers of rigid-flex connect to one another electrically through vias.

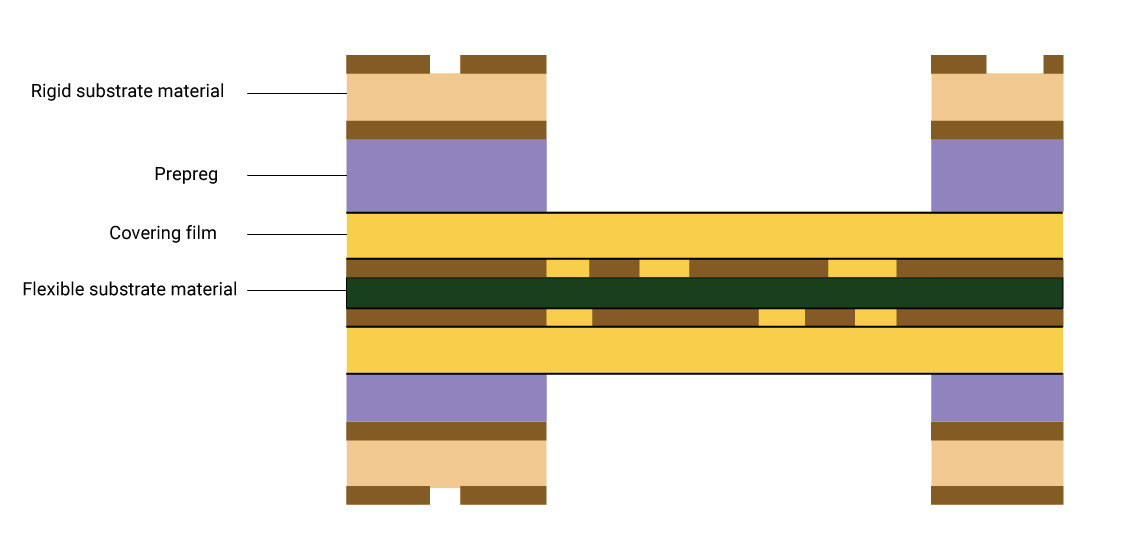

Generally, these PCBs have multi-layer options. The important aspect here is that the flex layers in these boards are always placed at the center of the stack-up. This provides mechanical support for the flex layers during the assembly process. The basic structure of a rigid-flex circuit is shown in the image above.

Flex PCB Design Guide

10 Chapters - 39 Pages - 45 Minute ReadWhat's Inside:

- Calculating the bend radius

- Annular ring and via specifications

- Build your flex stack-up

- Controlled impedance for flex

- The fab and drawing requirements

Download Now

Points to consider during rigid-flex assembly

Rigid-flex PCBs are assembled similarly to rigid boards. However, there are a few differences.

Rigid-flex materials

Rigid-flex boards are fabricated using the same materials that hardboard and flexible boards are built with. The only difference is that they are built using no-flow prepreg. No flow prepreg is essential in rigid-flex manufacturing, as it flows up to the edge of the rigid-flex transition area without flowing out onto the flexible sections of the board.

Baking rigid-flex PCBs

Generally, the materials used in these boards (flex layers, coverlays, and bondplies) absorb water from their environment. The absorbed water will greatly expand during the thermal excursion of assembly and will damage the board. Hence, it is necessary to bake these boards prior to the assembly process.

Rigid-flex arrays

Generally, fabricators and assembly houses prefer to have rigid-flex circuits supplied in arrays. This holds the boards stable during assembly. Once the assembly process is completed, the boards are removed from the arrays. Always contact your manufacturer to know more about the array requirements.

To understand how these boards bring down the overall price, read rigid-flex cuts assembly costs.

Rigid-flex assembly notes

Follow these guidelines:

- If components are placed close to the flex section, have stiffeners around the flex area.

- If the stiffeners are used for mechanical reasons, try to place components over the stiffener or rigid area.

- Flex circuits typically have SMT components on one only side of the board.

- Rigid-flex circuits are stiffened along most of their surface, with relatively small areas left unstiffened – the hinges or flexible arms.

- Apply stiffeners on the opposite side of SMT components and on the same side for through-hole components.

- The pre-bake cycle eliminates any moisture retained in the board and allows for improved assembly yields and reliability. However, if boards are assembled immediately after manufacturing, there is no need for pre-bake. Since Sierra Circuits manufactures and assembles under one roof, we eliminate the need for pre-bake.

Rigid-flex boards have effectively reduced a product’s size without compromising the quality. They can solve contact and intense heat problems caused by harnesses and connectors, drastically improving the reliability of devices.