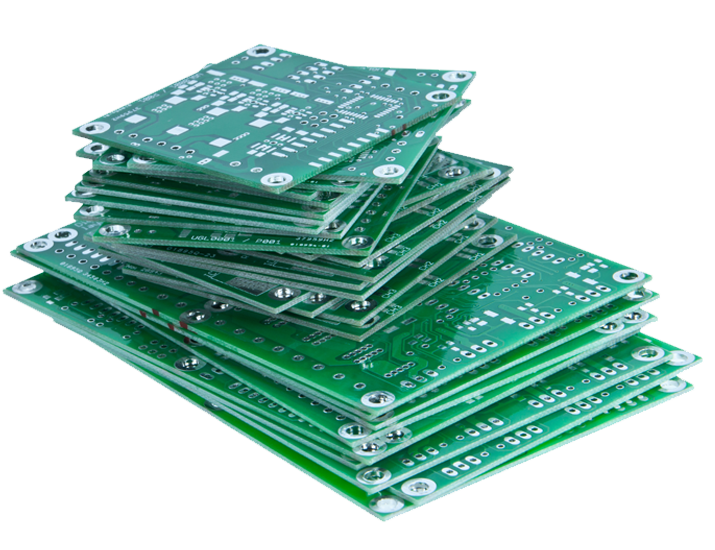

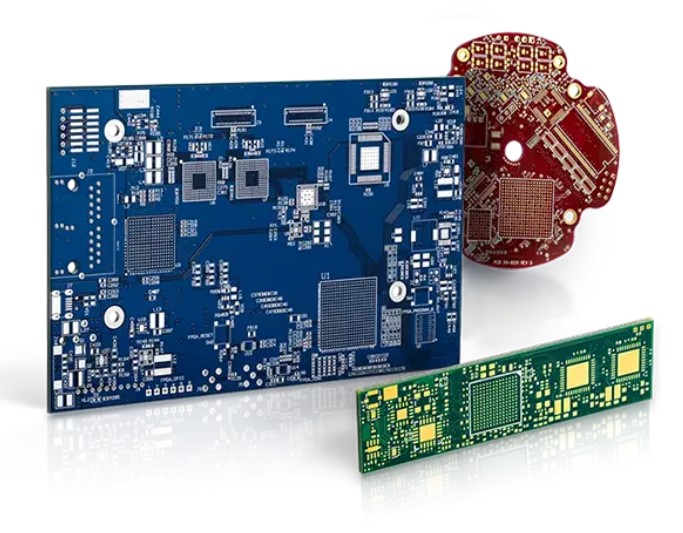

On top of our prototyping specialization, we now offer PCB mass production. Indeed, in 2022, Sierra opened its first facility for large-scale PCB fabrication with products and services that include:

- Flex and rigid-flex

- HDI

- Microelectronics

- Military grade

- Controlled impedance

- Flying probe testing

- PCB design support

Sierra Circuits supports IPC-2581.

Essential traits of large-scale PCB fabrication houses

High-volume production is the final step after successful prototyping and testing of the circuit board. You have decided on the design, component assembly, and circuit functionality. Therefore, cost-efficiency and a steadfast supply chain will now become prominent. The primary attributes of an effective mass board production include:

Reliability: The manufacturer should be capable of building reliable boards in large quantities over multiple production cycles. To achieve this, skilled design experts and automated infrastructure are essential.

Quality checks: Higher quantity means thousands of boards need to be tested for defects and functionality issues. Your CM needs to have an industry-standard quality assurance process.

Lower per unit cost: Typically, the per unit cost of a product will reduce when purchased in large quantities. Hence, PCB manufacturing will be more cost-effective.

PCB mass production with Sierra

Sierra Circuits offers large-scale circuit board fabrication and assembly with testing and quality control measures. Our expert team will assist you at every stage of design and DFM analysis.

Access to cutting technology is crucial when you are fabricating an advanced board with tighter tolerance, special materials, fine lines, and higher component density. It will help you achieve desired results with a better yield.

The fabricated board should adhere to the industry standards and regulations for medical, automobile, military, aerospace, and consumer electronics applications. Our certifications include:

- IPC Manufacturers Qualification Profile (MQP)

- IPC-A-600

- ISO 9001:2015

- AS9100D – military and aerospace

- NADCAP

- ISO 13485:2016 – medical devices

- Mil-Spec and DLA approved

- ITAR registered

- Underwriters Laboratory certified for flex, rigid-flex and rigid PCBs

- Compliant with RoHS/REACH standards

We have state-of-the-art facilities that facilitate your efficient, high-volume PCB production with advanced equipment including:

- Laser direct imaging (LDI)

- Automatic cut sheet laminator

- Post etch punch

- Vacuum lamination press

- Registration, laser, and mechanical drill System

- Electroless copper, strip-etch-strip, and copper plating lines

- Organic surface protectant line

- Mechanical de-burring and non-conductive via hole plugging

- High-resolution printing

- LPI coating

- SMT assembly lines

- Material handling

- Custom thermal profiles

- 3D X-ray inspection

- Solder paste inspection

- 3D AOI (Automatic Optical Inspection)

Maintaining an undisrupted supply chain

One of the main challenges of high-quantity PCB production is supply chain risk management. There can be disruptions due to natural calamities, political disputes, cyber-attacks, and socio-economic emergencies. You need a qualified CM that can efficiently evade crises and secure your business. A good fab house will always:

- Be compliant with the local and global authority regulations

- Maintain process transparency

- Provide efficient customer support

- Conduct quality checks at every step

- Possess strong recovery plans in case of failures

Design guidelines for successful high-volume fabrication include:

- Understand the manufacturer’s capabilities and tailor your design accordingly.

- Adhere to the suggested DFM and DFA guidelines as little or no layout change can be done at the final production stage.

- Know the component kitting requirements if you opt for consigned assembly.

Product Promise

We deliver high-quality large-scale PCB fabrication for large OEMs in need of advanced high-reliability electronics while offering a strong recovery plan and well-trained associates so you don’t have to worry about supply chain disruptions.

Our PCB mass production capabilities

For a swift, reliable, and consistent supply of your circuit boards, Sierra has a robust and clear contingency plan with two well-equipped facilities in operation.

Easy transition

If you opt for two different CM for prototyping and production, the manufacturer producing the final product should be able to grasp the challenges and design complexities of prototyping and alleviate them in their process. Hence, it is better to prototype where you build your production run.

No limits per order

As we operate to annual estimated usage, there is no restriction in the number of circuit boards per order. We can accommodate orders ranging from a few thousand to millions per order.

Multiple panel sizes

Different panel sizes to choose from (12×18, 18×24, and 21×24). The average number of PCBs per panel is 6, and 20 panels can be produced in a lot. So we can fabricate 600–800 boards per day.

Trusted by innovators

Engineers and PCB designers at the world’s most innovative companies choose Sierra for the highest quality PCB mass production, right here in the USA.

Efficient large-scale PCB production For your industrial requirements

For business owners thinking to scale their production or OEMs who need a steady supply of circuit boards, Sierra will help you build high-yield, cost-effective, and quality circuit boards with a quick turnaround time.

IDEAL FOR:

- Medium to large-sized OEMs looking for mass-produced PCB panels with a stable supply chain

- Business owners or designers venturing from prototyping to high-volume production

Manufacturing Equipment at Sierra Circuits

Our 70,000 sqft state-of-the-art campus in the heart of Silicon Valley contains the most advanced equipment required for the manufacture and assembly of your PCBs. Whether you’re looking for standard quick turn PCBs or boards with the tightest tolerances, made from exotic metals, there’s a reason Sierra Circuits leads the industry in quality and performance.

Fabrication, Procurement, & Assembly. PCBs fully assembled in as fast as 5 days.

- Bundled together in an entirely-online process

- Reviewed and tested by Engineers

- DFA & DFM Checks on every order

- Shipped from Silicon Valley in as fast as 5 days

Fabrication. Procurement & Assembly optional. Flexible and transparent for advanced creators.

- Rigid PCBs, built to IPC-6012 Class 2 Specs

- 2 mil (0.002″) trace / space

- DFM Checks on every order

- 24-hour turn-times available

Complex technology, with a dedicated CAM Engineer. Stack-up assistance included.

- Complex PCB requirements

- Mil-Spec & Class 3 with HDI Features

- Blind & Buried Vias

- Flex & Rigid-Flex boards