Automated optical inspection (AOI) is an inspection technique used in various electronic products to ensure quality standards.

What is AOI?

Automated optical inspection is a visual quality control method used for identifying defects that can occur during PCB manufacturing and assembly stages. In this technique, a camera scans the circuit board to examine various surface feature defects such as stains, scratches, open circuits, and short circuits. It also checks for missing, incorrect, and wrongly placed components.

Your manufacturer will run the board through an AOI device after placing all the components and then again after soldering the board. Throughout this process, multiple images are captured by the camera. These images are used to generate a standard, commonly termed as golden standard, for the circuit board after a successful assembly.

In the subsequent production runs, AOI scans and compares new images with the existing golden standard. When it comes across places that don’t match with the standard, it will indicate such areas as potential defects. Later, technicians will identify such errors and find out the possible solutions to rectify them.

Design for Testing Handbook

7 Chapters - 28 Pages - 45 Minute ReadWhat's Inside:

- PCB testing strategies

- Guidelines to design and place a test point for FPT

- Directives to make your board ICT compatible

- Benefits and drawbacks of various testing methods

- Defects that you can identify through board testing

Download Now

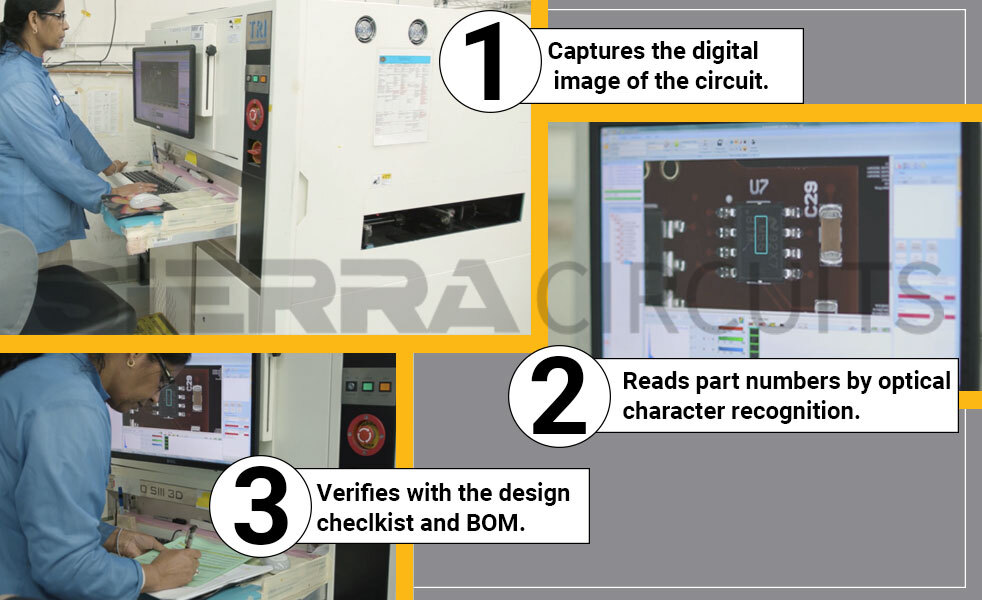

How does automated optical inspection work?

AOI system employs lighting, machine vision camera, high-resolution images, and processing software.

Lighting for visual inspection

Proper lighting/illumination of the component is a prerequisite for an AOI system. This is because it needs a clear vision to verify different parts and features that are under inspection.

Previously, AOI machines used different kinds of lights such as incandescent, fluorescent, infrared (IR), and ultraviolet (UV). The new machines incorporate LEDs as the light source. The lighting system consists of red, white, green, and blue LEDs in a configurable lighting module. These LEDs provide an even and consistent form of lighting.

The lighting angle also matters. During PCBA, light can be blocked by taller components from reaching shorter components. And some features need a very low illumination angle. Hence, an AOI system must have light sources from various angles to provide optimum overall lighting. Understand the role of quality assurance in PCB manufacturing from design to final testing.

Machine vision camera

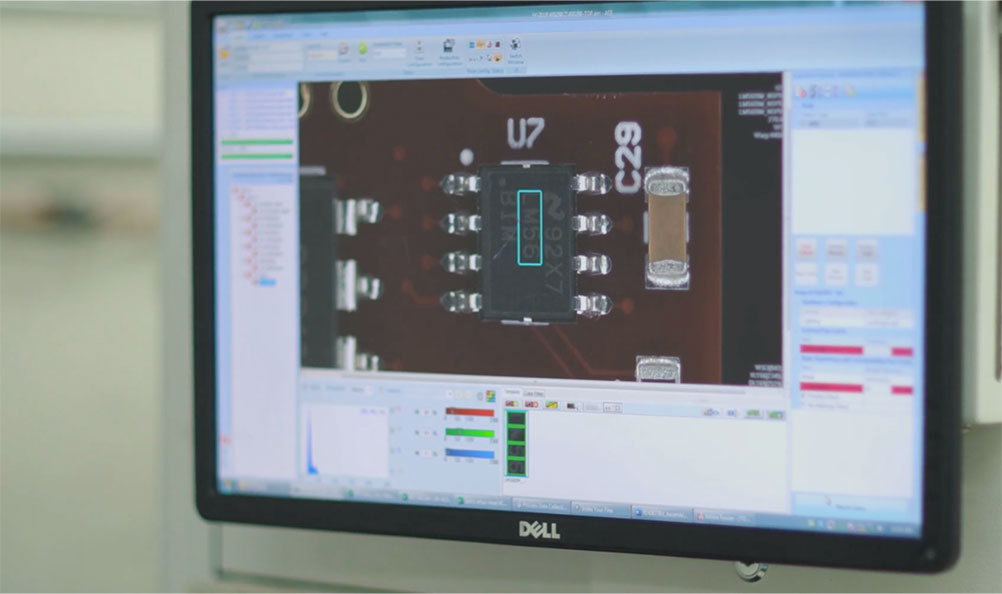

An automated optical inspection camera is an expensive part of the system. It captures an image of the product and sends it for evaluation through the processing software in the AOI machine. The modern equipment use cameras that range from extended graphics array (XGA) to multi-megapixels high-resolution sensors. The latest cameras can even click 100 frames per second (fps). This proves that AOI is efficient enough to generate a large amount of data.

- Optical system resolution: In automated optical inspection, optical system resolution/imaging resolution is critical. It determines the extent of the details visible to the AOI. Key factors like inspection speed, accuracy, and size of the smallest component used on the circuit board influence the selection criteria of system resolution. It is also determined by the camera’s sensor, lens, and the distance from the board.

- Field of view: Field of view (FOV) is defined by the resolution of the camera sensor. It is the area of the board that can be covered by a single image. Wider FOV scans the circuit board using fewer images and a low number of frames per second. Conversely, narrow FOV has a higher frame rate.

AOI processing software

The specifications or the accepted standard of a product need to be fed into the AOI system. This will be utilized as a reference (gold standard) during the inspection process.

There are two ways:

1. Golden board method: The AOI machine selects a good product and scans it through various required stages. It captures the golden standard and uses it for further production.

2. Algorithm-based programming: The AOI system generates its profile for the product by inducting product data/specifications into it.

Automated optical inspection is a simple and widely used approach for PCB inspection. Demand for the AOI system is increasing with the rapidly growing electronic industry. In simple words, AOI ensures the quality of the board isn’t compromised.