Annular breakouts occur when the drilled via is not fully encircled by the pad. This can happen when the lamination process causes the PCB to shift and move away from where parts (pads, traces, etc.) should be. Breakouts can occur during the drilling process. Breakouts of 90 to 180 degrees can occur.

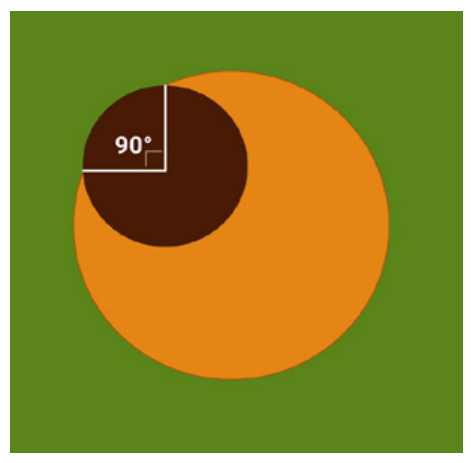

A 90-degree breakout occurs when the section of the via, drifted outside the pad, is 1.4 times the radius of the via in length. This is allowed in class 2 boards as long as the conductor junction width is wide enough.

A 180-degree breakout is when the width of the breakout is the same as the diameter of the via. This is not allowed in an IPC class 2 nor class 3 PCBs.

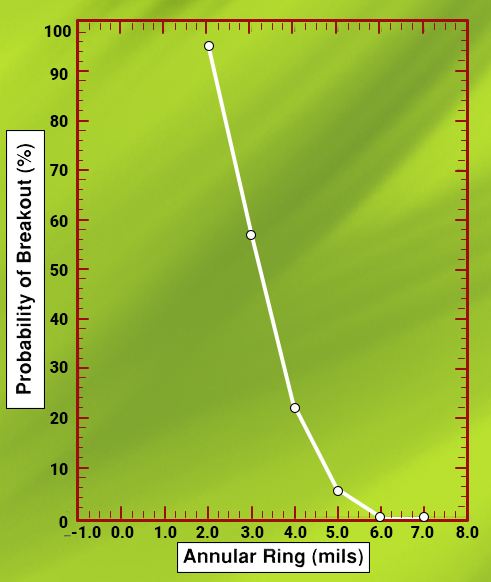

For board designs that cannot tolerate breakouts, the annular ring needs to be a minimum of 5 mils or greater. This is displayed in the graph given below:

Boards with annular ring widths lesser than 5mils have a higher probability of breakout ranging from 22% for a 4 mil ring width to a maximum of 98% probability for a ring width of 2 mil. So board designers will have to use microvias of 5 mil with a 5% probability of breakout.

One-stop PCB assembly services, capabilities, and testing

We source components from chip manufacturers across the globe, including Mouser, Digi-Key, Arrow Electronics and others. We also warehouse a significant inventory of common parts. If we cannot source a specific component, our engineers will make recommendations for fair-price alternatives. Get started now.

IPC Class 3 Design Guide

8 Chapters - 23 Pages - 35 Minute ReadWhat's Inside:

- IPC guidelines for manufacturing defects

- IPC standards for assembly processes

- Common differences between the classes

- IPC documents to set the level of acceptance criteria