RF / MW PCB manufacturing challenges

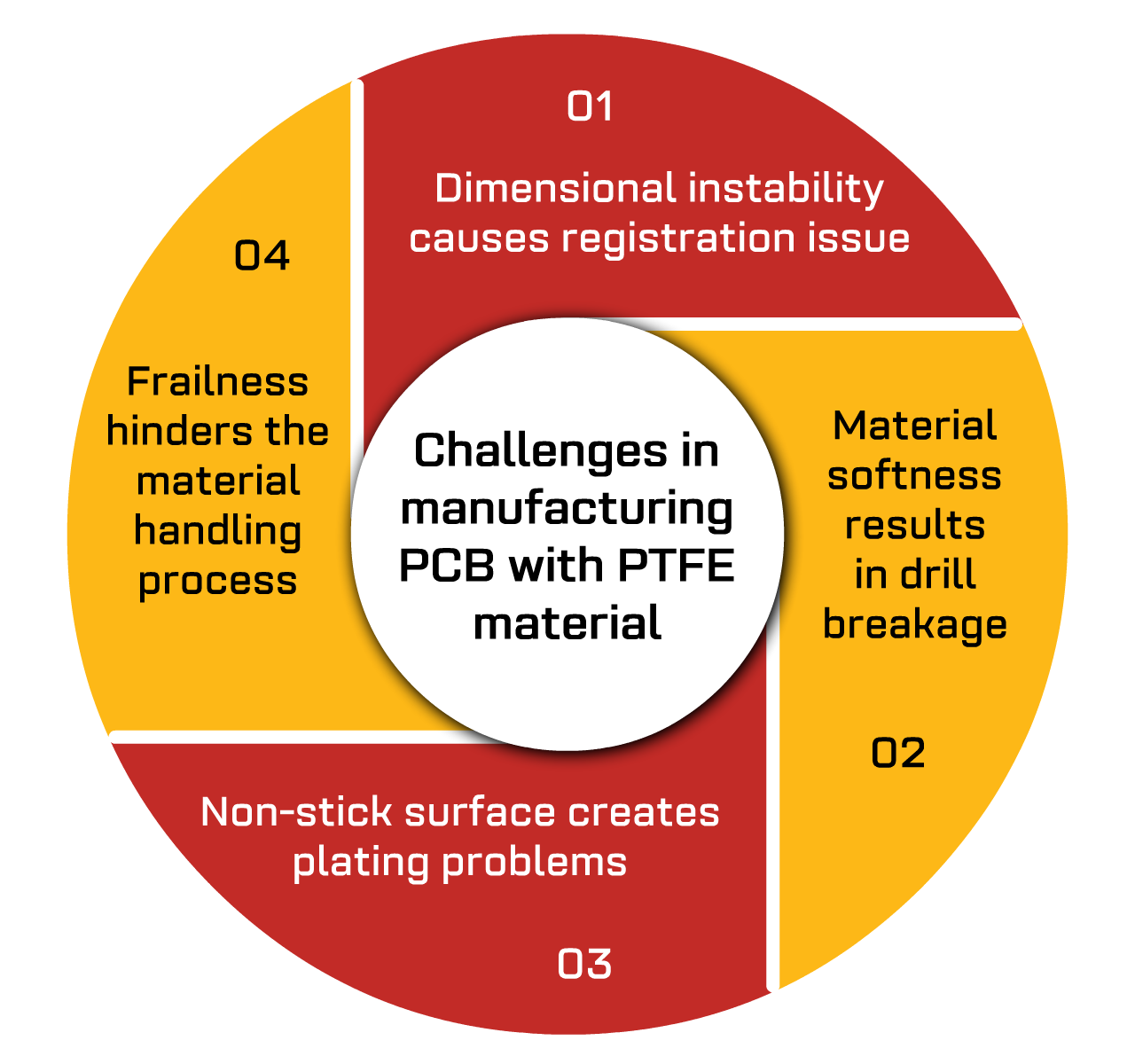

Handling PTFE materials

- Ceramic-filled PTFE materials are fragile and can easily break during the manufacturing process.

- Registration issues can also occur during lamination as they lack dimensional stability.

- Since PTFE laminates are soft, drill bits are likely to wander and break, so they need to be constantly replaced.

- Due to their non-stick properties, it is hard to plate copper or apply a solder mask.

- As PTFE materials are expensive, any manufacturing issues will significantly increase the lead time and cost.

Hence, it is crucial to partner with an RF PCB manufacturer who can address these challenges and fabricate your boards precisely.

Though working with non-PTFE materials is easier, handling high-frequency signals demands more design optimization. This requires your microwave PCB fabricator to stick to tighter tolerances.

Why partner with Sierra Circuits for RF PCB manufacturing?

- Our fab engineers have extensive experience fabricating radio frequency circuit boards. We have perfected the process of supporting stack-ups, drilling, and etching.

- At Sierra Circuits, everything from material movement to feeding data to the machine is automated. The design rules are scripted into the system, making RF and microwave manufacturing more efficient with reduced human errors.

- For precision, we utilize self-learning automated scaling software (XACT). This system analyzes material type, thickness, and copper weights on individual layers to provide a scaling prediction on material shrinkage. This data is used to improve the accuracy of the laser direct image and CO2 drilling system.

- We also have a mechanical vision drilling and routing machine that reduces the errors by automatically realigning the board for multiple drill programs, which are often seen in via-in-pad and back drills.

- We have dedicated teams for DFM analysis, stack-up preparation, component sourcing, manufacturing, assembly, and testing. Once you place an order, these teams will collaborate seamlessly to deliver error-free prototypes.

Our capability of producing high-quality boards makes us the industry’s trusted RF PCB manufacturer.

- Number of layers: 2-30

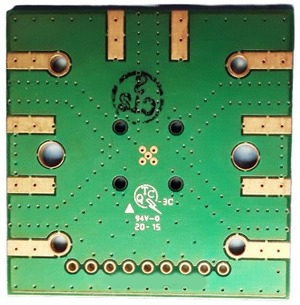

- Hybrid stack-ups with PTFE and non-PTFE combinations

- Sequential lamination up to 4 lamination cycles

- Minimum 2-mil trace and space

- Controlled impedance with +/-5% tolerance when you work with us right from the beginning of your design phase

- .75:1 aspect ratio for microvias

- 20:1 aspect ratio for through-holes

- Plasma and sodium etch hole treatment

- Electrolysis copper for metallization

- Minimum 5-mil and 3.5-mil hole diameter for mechanical and laser drill

- Back drill with minimum 12-mil hole and +/-1 mil depth tolerance

- +.5 mil tolerance for laser routing and +/- 3 mil for mechanical routing

- Selective and full-body hard and soft gold plating up to 120µ

- ENIG, immersion tin, and ENEPIG surface finishes

- Special features: countersink hole, castellation, cavities, edge plating, and gold fingers

These are Sierra Circuits’ standard capabilities. If your requirements are beyond these standards, talk to our manufacturing experts at +1 (800) 763-7503 and share your design requirements.

RF material selection and stack-up preparation

At higher frequencies, the signal degrades due to insertion loss. This can occur due to conflicting dielectric properties, copper profile, and surface finish.

- Choose a low-tooth copper profile to avoid skin effects in your microwave and radio frequency circuits.

- Pick ENIG, immersion tin, or ENEPIG surface finish to prevent signal losses.

- Select a substrate with a low dielectric constant, low loss tangent, and stable electrical properties over a wide frequency range. Low Dk materials are usually PTFE-based, like Rogers RO4000 series or FR-4 with enhanced RF properties.

Before choosing the substrate, check their availability with your RF and microwave PCB manufacturer.

- A hybrid stack-up with mixed materials is also a viable option for RF/microwave designs. Here, go for low Dk laminates specifically for layers with critical traces and FR-4 for the rest. This provides better layer customization for signal integrity, thermal management, and signal isolation.

- Note that the chosen materials in hybrid stack-ups must have matching CTEs to avoid cracks during the lamination process.

At Sierra Circuits, we control curing parameters like temperature, pressure, and time to minimize inherent and residual stress, thus eliminating the risk of layer misalignment and delamination.

Commonly used RF materials with Dk and Df values

The table below shows RF laminates with their dielectric constant and loss tangent values. Try our PCB Material Selector tool to choose the best RF substrate for your design.

| RF material | Manufacturer | Material type | Dk value (at 10 GHz) | Df value (at 10 GHz) |

| RO4350 B | Rogers Corporation | Ceramic-filled PTFE | 3.48 | 0.0037 |

| RO4003 C | Rogers Corporation | Ceramic-filled PTFE | 3.38 | 0.0027 |

| RO3035 | Rogers Corporation | Ceramic-filled PTFE | 3.5 | 0.0015 |

| RO3003 | Rogers Corporation | Ceramic-filled PTFE | 3 | 0.0010 |

| FR408HR | Isola | Multifunctional epoxy | 3.65 | 0.0095 |

| I-Speed® | Isola | Multifunctional epoxy | 3.63 | 0.0071 |

| I-Tera® MT40 (RF/MW) | Isola | Hydrocarbon-PPE | 3.45 | 0.0031 |

| Isola Astra MT77 | Isola | Hydrocarbon-PPE | 3 | 0.0017 |

| Tachyon-100G | Isola | Hydrocarbon-PPE | 3.02 | 0.0021 |

| Megtron6 R-5775 | Panasonic | Hydrocarbon-PPE | 3.35 | 0.0040 |

Optimizing your RF and microwave circuit design

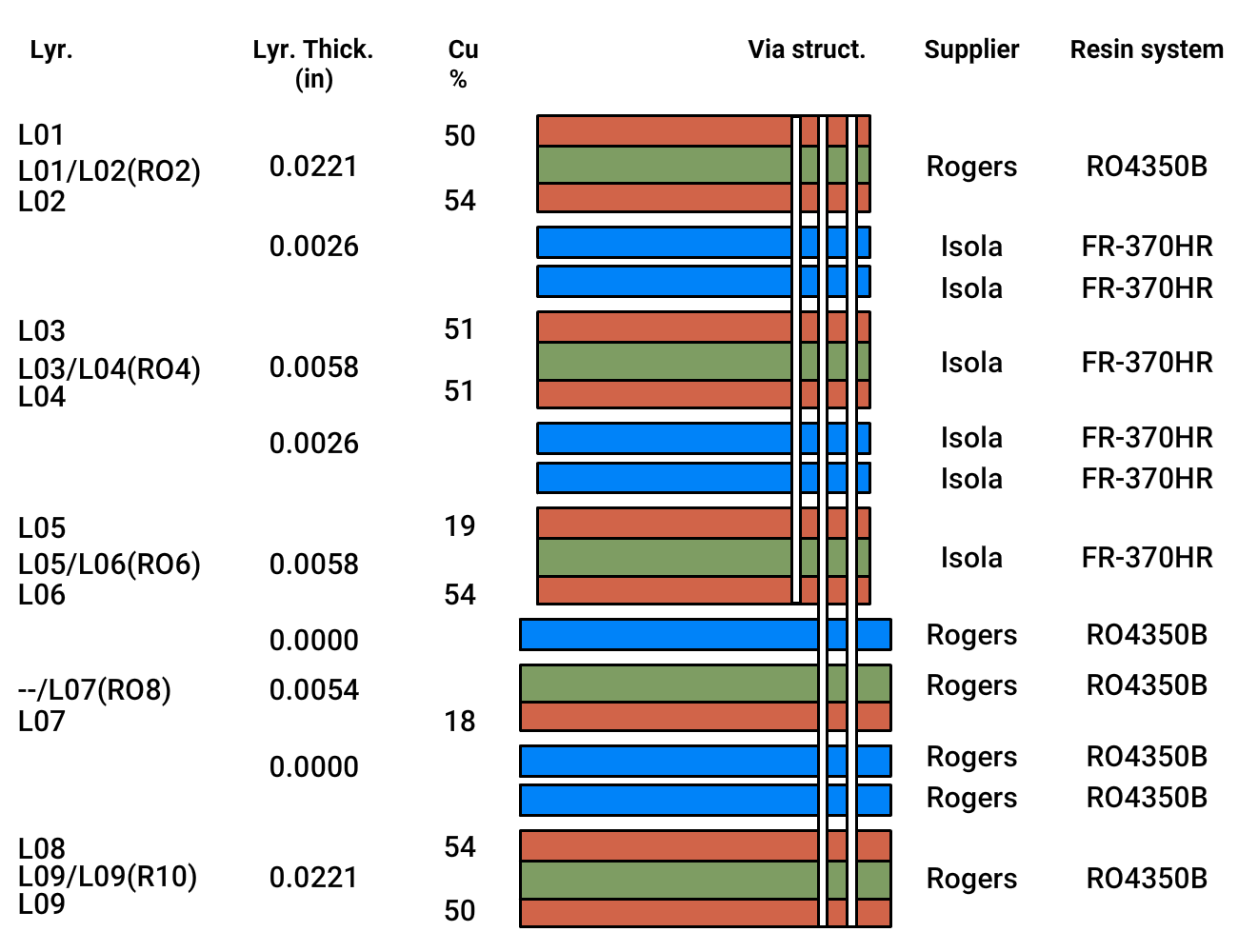

The key difference between RF and microwave PCBs is their operating frequencies. Radio frequencies range from 10 MHz to 1 GHz, while microwave frequencies are above 1 GHz.

At higher operating frequencies, circuit boards are prone to signal losses, EMI, crosstalk, ringing, and reflections.

Here are the top 6 microwave and RF circuit board design tips:

- Consider distributed and lumped elements when designing transmission lines in the RF frequency range. Generally, a 50Ω coplanar structure is used for minimum loss and maximum power transfer.

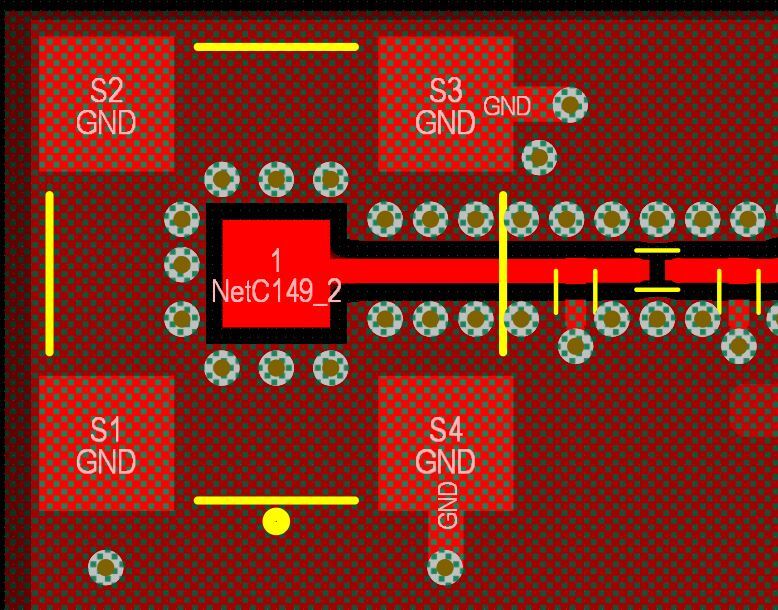

- Have a dedicated ground plane for each RF layer and implement ground stitching vias to distribute the ground connection.

- Apply DRC for stitching vias:

- Default via/pad clearance: 20 mil

- Minimum boundary clearance: 20 mil

- Incorporate decoupling capacitors and LC filters to suppress high-frequency noise.

- Choose materials with a dielectric constant of 3-3.5 and a loss tangent of 0.0022-0.0095 for minimal signal loss.

- Match the impedance of traces, components, and antennas to minimize signal reflections. Use our Impedance Calculator to design your RF PCBs.

Product Promise

We have skilled and experienced design experts to help you optimize your RF and microwave PCB layouts to achieve desired functionalities with excellent signal integrity. You can count on us to fabricate and deliver high-quality boards that meet your design, cost, and time-to-market requirements.

Sierra Circuits’ high-frequency PCB capabilities

We pay close attention to every detail of your designs and customize our RF PCB manufacturing process to build high-quality boards.

Design assistance

Sierra Circuits has seasoned engineers and experts with over 30 years of experience designing circuit boards. We can help you build efficient stack-ups, design well-planned layouts, and conduct DFM analysis to ensure your RF PCB and microwave circuit design is manufacturable.

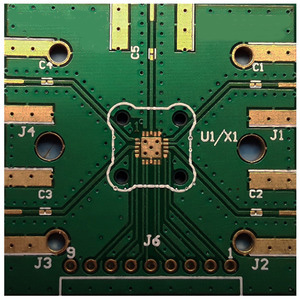

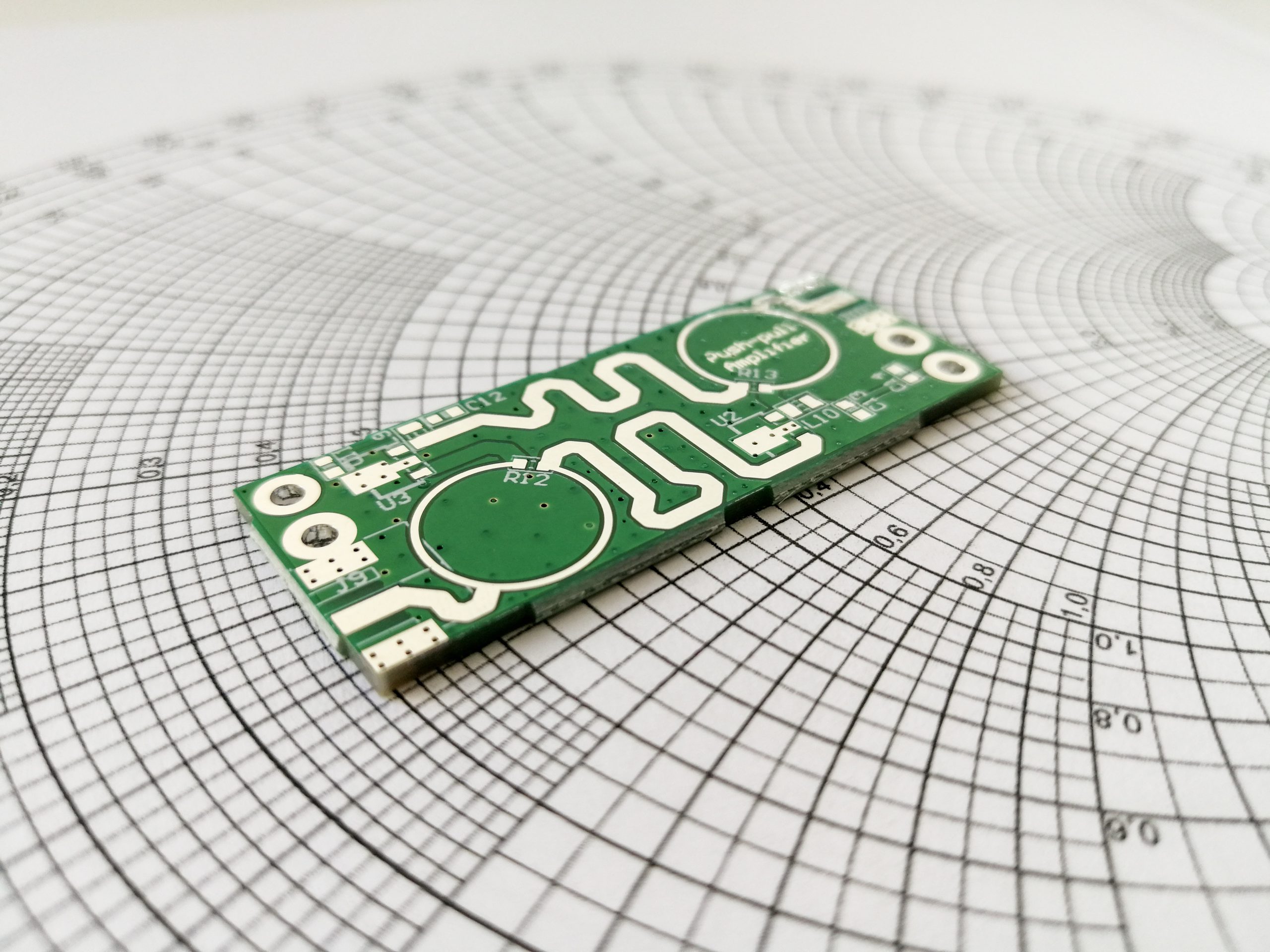

RF and microwave PCB manufacturing and assembly

We have a well-equipped facility and experienced staff for RF PCB manufacturing. We can efficiently handle hybrid stack-ups, tight tolerances, drilling, and etching of PTFE materials. We also provide SMT, BGA, through-hole, and mixed assembly services.

Component sourcing and stocking

Managing material and component availability is a major pain point in RF board fabrication. To mitigate this, Sierra Circuit offers a Customer Owned Inventory to help reduce supply chain risks.

Trusted by innovators

Engineers at the world’s most innovative companies choose Sierra Circuits for the highest quality rigid PCB manufacturing and assembly, right here in the USA.

Reliable PCBs for allRF and microwave applications

Whether you’re a designer building boards for communication systems or a large-scale consumer electronics manufacturer, Sierra Circuits fabricates reliable RF and microwave boards that fulfill your high-frequency operation requirements.

IDEAL FOR:

- Wireless communication gadgets such as smartphones, tablets, and routers

- Satellite communication, radar, and electronic warfare systems

- High-frequency signal processing in healthcare devices

- Automotive electronics such as collision avoidance systems, GPS navigation, and advanced driver assistance systems (ADAS)

We are certified to build your RF and microwave boards that adhere to the following standards:

- IPC Manufacturers Qualification Profile (MQP)

- IPC-A-600

- IPC-6012 standards

- ISO 9001:2015

- AS9100D – military and aerospace

- NADCAP

- ISO 13485:2016 – medical devices

- Mil-Spec and DLA approved for 4350 and hybrid constructions

- ITAR registered

- Compliant with RoHS/REACH standards

Equipment for manufacturing radio frequency PCBs

As one of the top RF and microwave PCB manufacturers, we have a state-of-the-art facility to manufacture circuit boards according to your design requirements.

Pure PTFE is UV-transparent, and ceramic-filled PTFE reflects the laser; hence, normal laser techniques can not ablate materials. We combine multiple technologies, such as mechanical drilling, UV, and CO2 laser, to drill and cut laminates.

We also employ carbide or diamond-coated drill bits to perform precision drilling without compromising material integrity.

We ensure complete metallization of the exposed dielectric to eliminate voids and hole-wall detachment. Plasma and sodium etch (for thicker boards) treatments are performed before plating to improve laminate metalization.

We have automated pick-and-place machines that facilitate the assembly process. We implement vertical flying probe testing to check electrical connections and conduct cross-section analysis to verify the stack-up construction.

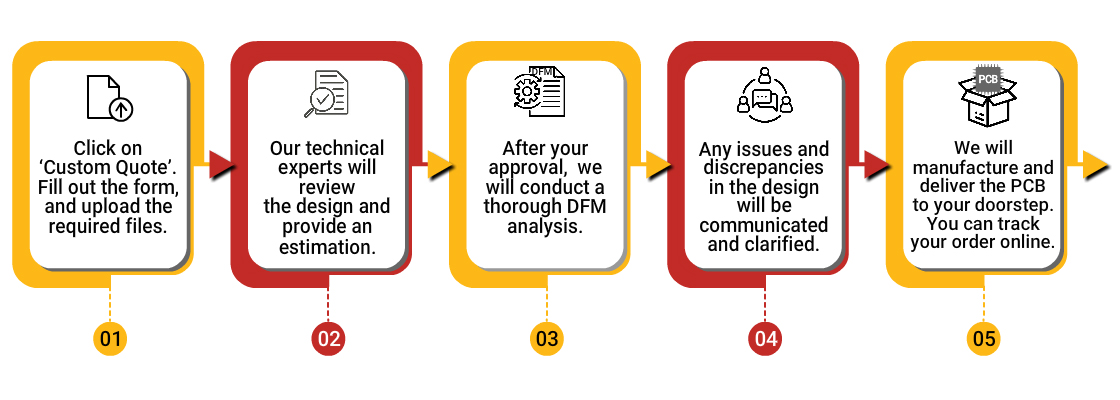

Fabrication, Procurement, & Assembly. PCBs fully assembled in as fast as 5 days.

- Bundled together in an entirely-online process

- Reviewed and tested by Engineers

- DFA & DFM Checks on every order

- Shipped from Silicon Valley in as fast as 5 days

Fabrication. Procurement & Assembly optional. Flexible and transparent for advanced creators.

- Rigid PCBs, built to IPC-6012 Class 2 Specs

- 2 mil (0.002″) trace / space

- DFM Checks on every order

- 24-hour turn-times available

Complex technology, with a dedicated CAM Engineer. Stack-up assistance included.

- Complex PCB requirements

- Mil-Spec & Class 3 with HDI Features

- Blind & Buried Vias

- Flex & Rigid-Flex boards