A bill of materials, or BOM, is a list of all the components needed to build a specific product. This list helps to keep a track of all the components during their purchase and assembly.

A PCB BOM serves as the reference for board assembly. This list contains all sorts of information regarding the components such as their quantity, manufacturer part number, reference designators, vendor name, footprint/size, specifications, etc.

Why is the PCB BOM file important?

The BOM provides a lot of information related to each component. It is through this file that the customer communicates everything about the components to be assembled on the board to the assembly unit. Apart from this, the bill of materials also helps the designers to estimate the cost of the required number of circuit boards.

How to prepare a bill of materials

A BOM is a simple Excel sheet with all the required information. It is possible to create it manually by entering all the required information. But to save time and effort, you can depend on the software that offers the option to generate your BOM. The most commonly used ones are KiCad, Altium Designer, and Cadence Allegro.

Each manufacturer suggests a specific format. So while preparing the list, the designer should ensure that they are using the same template suggested by the manufacturing company.

To learn how to create BOM files in KiCad, Altium Designer, and Allegro, check how to generate PCB assembly files.

KiCad Design Guide

10 Chapters - 161 Pages - 180 Minute ReadWhat's Inside:

- Creating a component symbol library

- Setting up board parameters and rules

- How to route differential pairs

- How to place of components

Download Now

Tips to keep in mind while preparing your BOM file

- Including everything: One should understand that all the components required for various versions of a circuit board are purchased referring to the BOM. Therefore, it is important to add each and every item required for the building of all the boards going for assembly in this list.

- Verified information: Make sure that the information available in the list is correct and has no errors so it doesn’t affect the quality of the product.

- Send the most updated version: Make sure that all the details given in the BOM are up to date.

What goes into a BOM file?

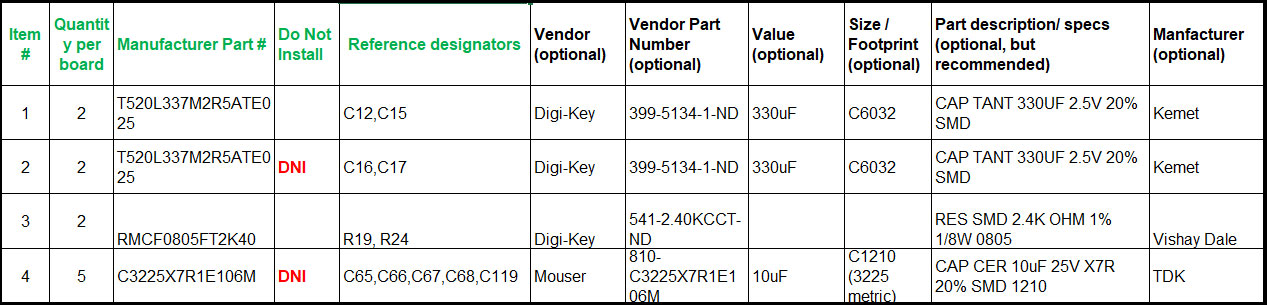

An example of a BOM

An example of a BOM

Even though the bill of materials templates differs from one manufacturer to another, the basic information available will be the same.

The Excel sheet consists of the following information:

- Quantity per board

- Manufacturer part number (MPN)

- Reference designators

- DNI/DNP

- Vendor (optional)

- Vendor part number (optional)

- Value (optional)

- Size/footprint

- Part description/specs

- Manufacturer (optional)

To learn more about this see, What is a Bill of Materials in PCB Design?