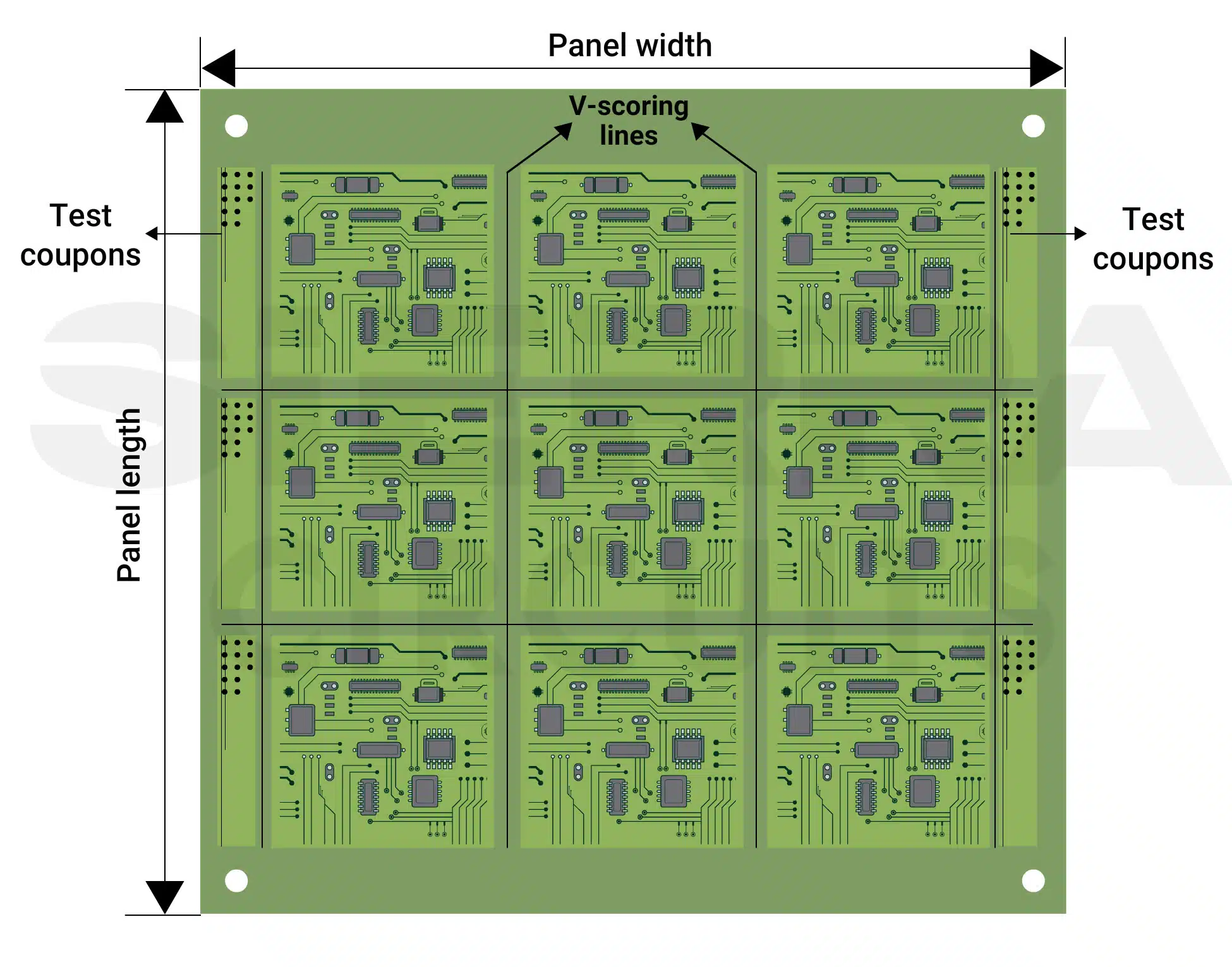

PCB test coupons are non-functional sections added to the edge of a circuit board panel. They are fabricated along with the actual boards and have the same layer stack-up, copper traces, and vias.

Manufacturers use these coupons for quality checks and also for performance standards before proceeding with the bulk production.

PCB designers do not place the test coupons in their layouts but provide the required details in the fab notes. Based on these fab details, fabricators will create the test coupons considering the final stack-up and impedance requirements.

Highlights:

- Test coupons are miniature replicas of the main board, placed on the panel edge.

- They are essential for verifying impedance, plating reliability, and solderability.

- Frequently used test coupons are A/B, D, and Type Z.

- These test coupons help assess via integrity, interconnect reliability, and impedance values in high-speed designs.

What are PCB test coupons used for?

Test coupons are implemented to validate whether the fabricated boards meet the electrical, mechanical, and reliability requirements without testing the actual product.

They help verify impedance uniformity, plating quality, via reliability, and solderability. The table below summarizes the key purposes of test coupons:

| Tests | Inspection parameters | Why it matters |

|---|---|---|

| Impedance testing | Trace geometry and impedance values | Ensures high-speed signals (USB, HDMI, DDR, etc.) meet design targets |

| Microsection or cross-section analysis | Layer registration, copper plating thickness, via quality, and solder mask alignment | Verifies fabrication quality according to IPC standards (e.g., IPC-6012/IPC-6013) |

| Plating and via reliability testing | Barrel plating uniformity, annular ring, and hole wall integrity | Validates via durability under thermal stress |

| Solderability testing | Surface finish quality on pads | Assures pad wetting during assembly |

3 frequently used circuit board test coupons

A/B, D, and impedance (Type Z) coupons are some of the most commonly used PCB test coupons. Let’s look at each of them in detail:

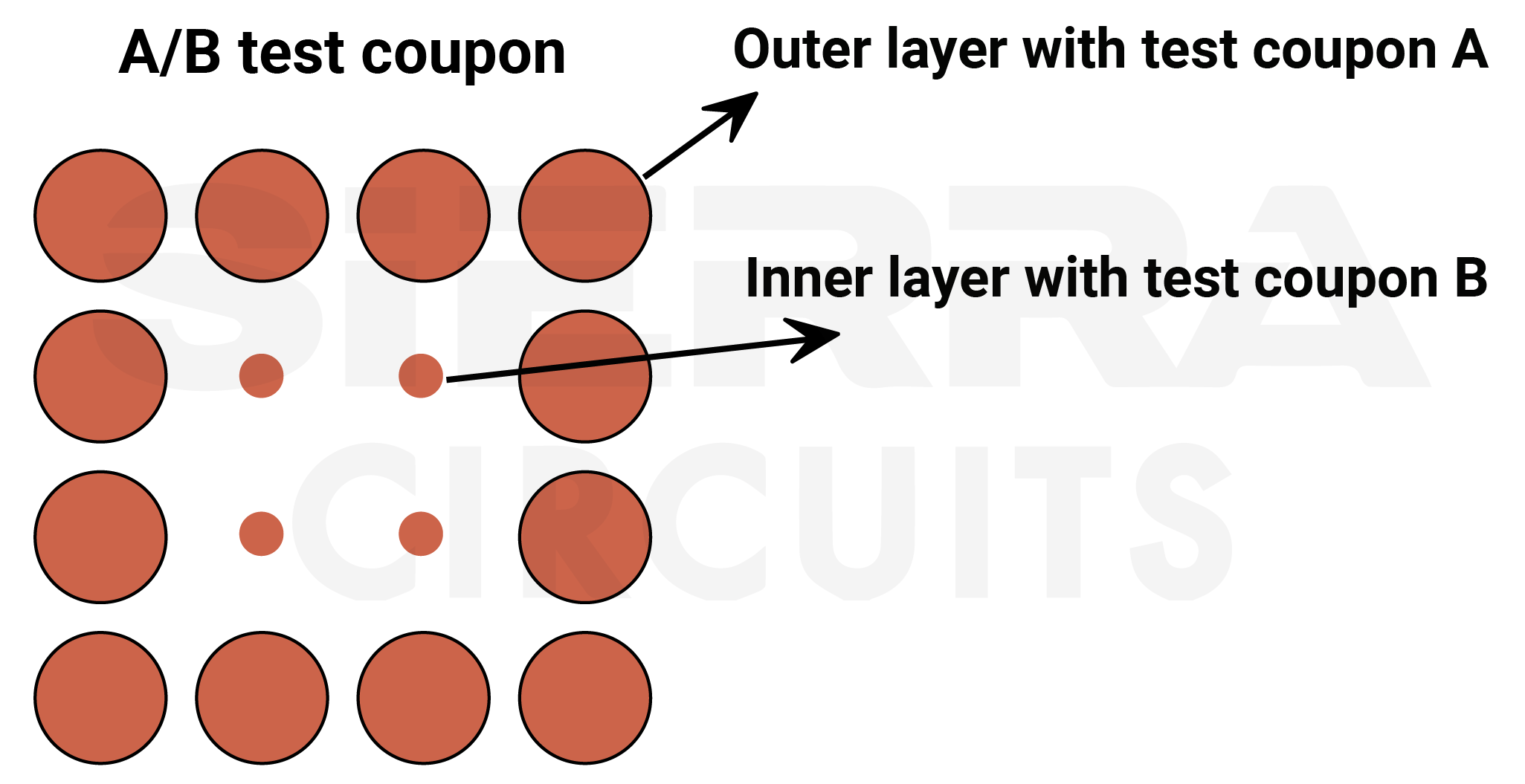

1. A/B coupons

These are combination test boards. The outer ‘A’ section typically contains larger plated-through holes (e.g., 1.905 mm diameter) simulating component holes for evaluation.

The inner ‘B’ section contains smaller PTHs/vias representing typical interconnects for assessing thermal stress reliability, registration, and plating quality.

Fabricators use these coupons for performing microsection analysis after thermal stress.

Sierra Circuits fabricates and assembles high-quality circuit boards. Every board we manufacture undergoes rigorous quality checks.

Check out our PCB manufacturing capabilities to learn more.

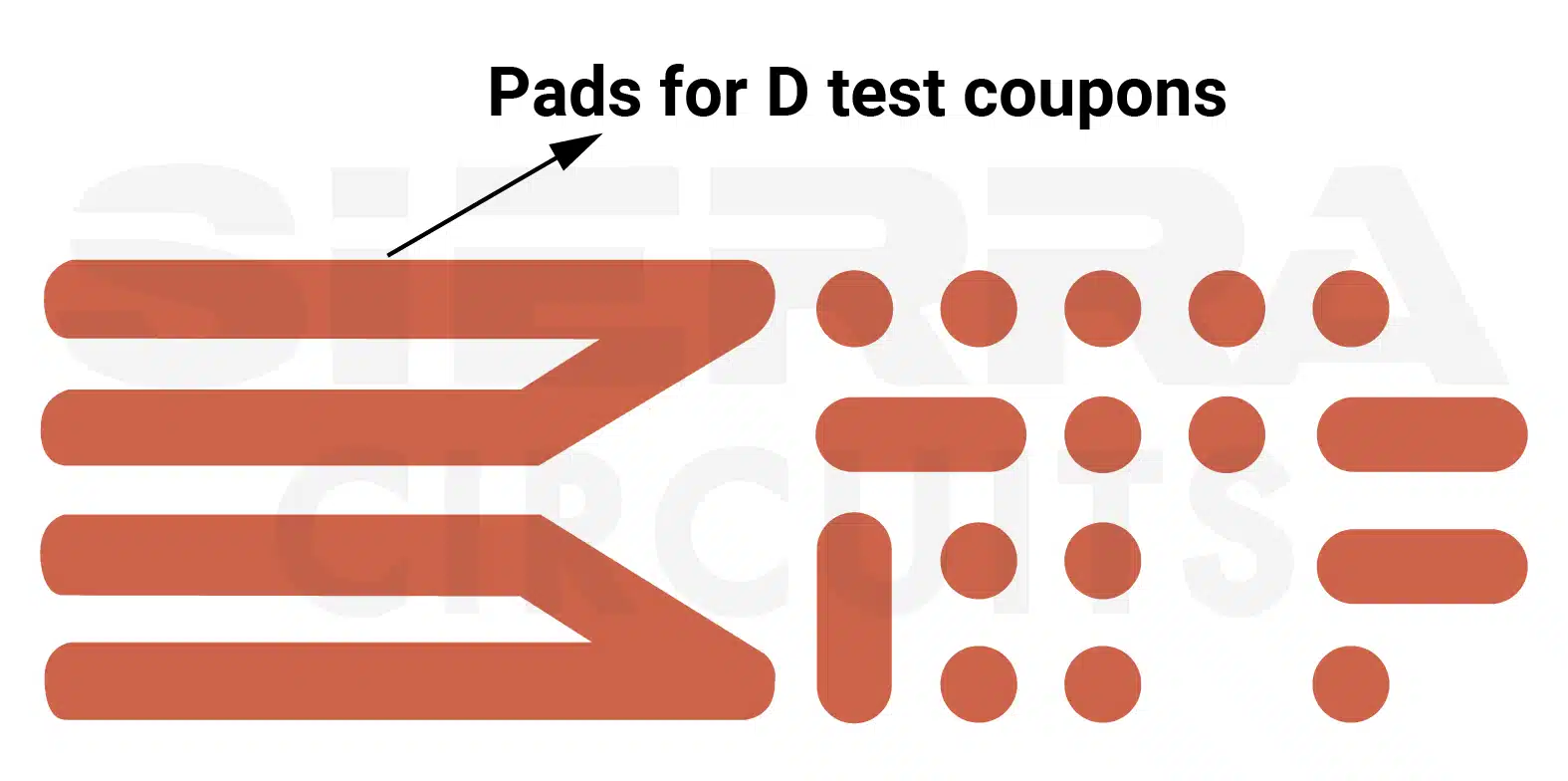

2. D coupons

They evaluate interconnect reliability through thermal stress. It typically contains two independent daisy-chained nets of vias or component holes.

D coupons allow continuous 4-wire resistance monitoring during thermal cycling or interconnect stress test (IST) to detect failures. A common acceptance criterion is <5% change in resistance after stress testing.

3. Impedance coupons (Type Z)

These test boards contain traces (single-ended, differential pairs, coplanar) that replicate the controlled impedance lines on the main board. Fabricators use TDRs to test these signal lines.

Manufacturers typically add ~6-inch (150 mm) long traces to the test coupons. These traces help accurately measure electrical parameters, and the coupons are stored with a unique code to identify which panel they belong to.

IPC-2221 defines the specification for these coupons. It also sets standards for testing surface insulation resistance (SIR – coupon H), solderability (coupon S), peel strength, moisture and insulation resistance (MIR), solder mask adhesion, and inner layer characteristics.

For details on class 3 test coupons, see IPC Class 3 PCB Design and Manufacturing Standards.

Who designs the board test coupons?

In most cases, the fabricator designs the test coupons. They create them based on the stack-up, impedance requirements, and the relevant IPC specifications.

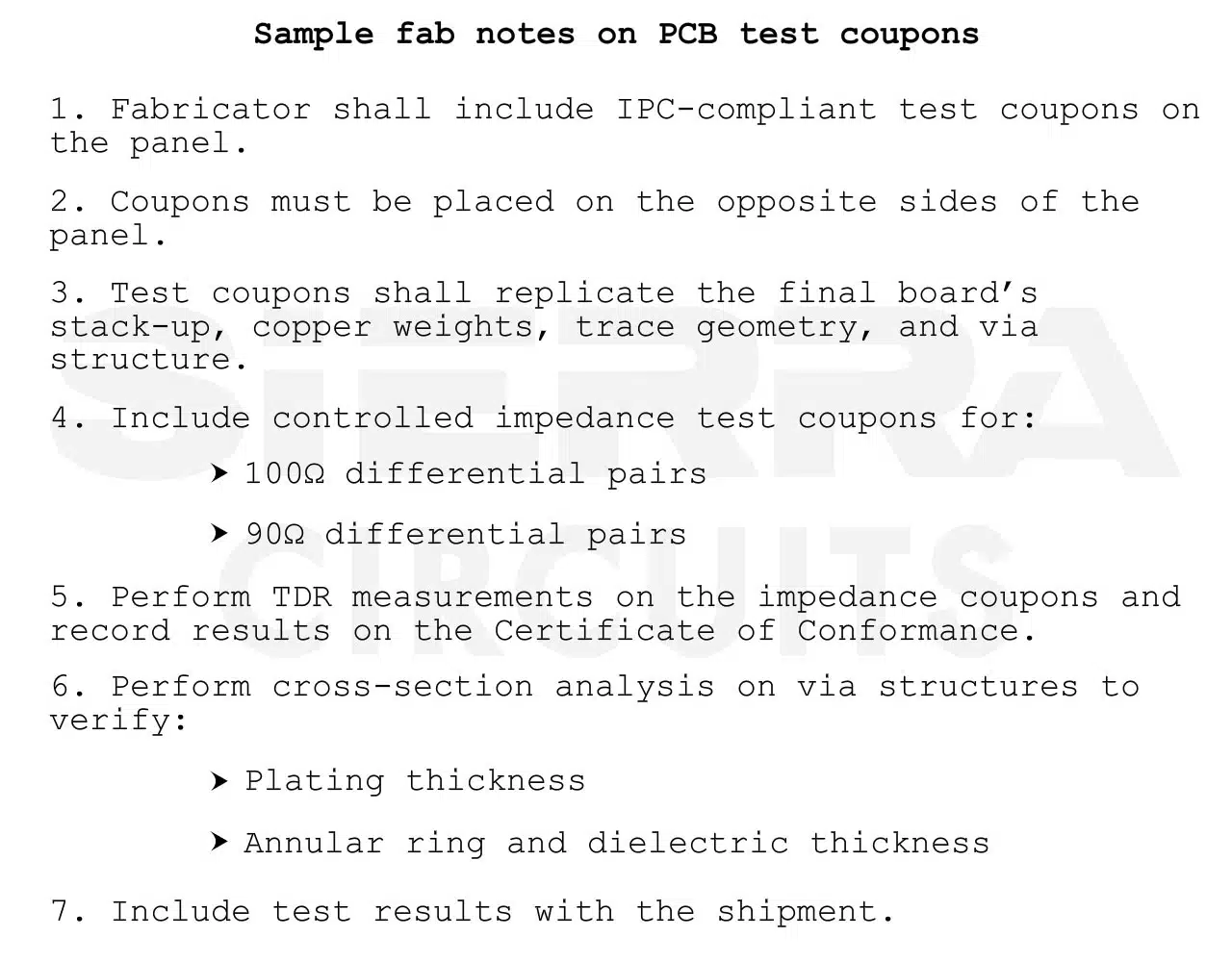

However, PCB designers should clearly mention the required IPC performance class and any specific coupon requirements in their fabrication notes.

Here’s an example of fab notes on PCB test coupons.

Download the PCB Fab and Assembly Notes for Designers.

PCB Fab and Assembly Notes for Designers

8 Chapters - 72 Pages - 70 Minute ReadWhat's Inside:

- Guidance on how to write comprehensive fab documentation

- Advanced fabrication notes for flex, rigid-flex, and hybrid stack-ups

- Difference between fabrication and assembly notes

- Assembly documentation essentials: BOM, X-Y data, and drawings

Download Now

PCB test coupons on the panel help ensure every board meets the required impedance, plating quality, and overall reliability standards.