Contents

On-demand webinar

How Good is My Shield? An Introduction to Transfer Impedance and Shielding Effectiveness

by Karen Burnham

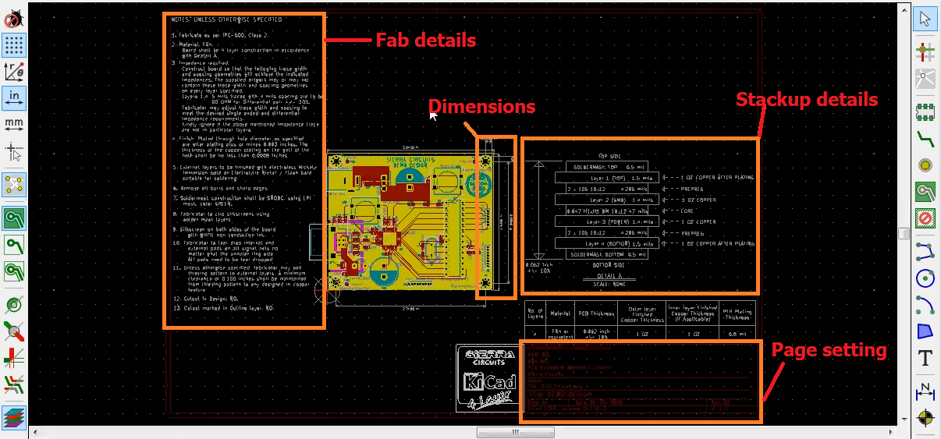

A PCB fab drawing is one of the different file types that convey the manufacturing details of a circuit board. The better the fabrication drawing, the easier the board manufacturing process. Hence, it is advisable for a designer to know about the information to be included in this file. In this article, we are going to have a look at the following details:

What is a fab drawing?

A fab drawing specifies all the important information, such as board outline, layer stack-up, drill chart, and many more, required to manufacture a PCB. Whenever a designer wants a circuit board to be fabricated, there are a number of ways to communicate all the requirements to the manufacturer. Fabrication drawing is one of them. If only a Gerber is provided, the manufacturer may miss out on the additional details concerned with the board.

Fab drawing, along with the assembly drawing, are the reference documents required to build and assemble a circuit board. These not only serve as an outline for both processes but also help in the inspection of the PCB quality.

How is a PCB fab drawing different from an assembly drawing?

As explained above, a fabrication drawing is meant to provide details about the manufacturing requirements of a circuit board. On the other hand, the assembly drawing mentions the details about how each and every component will be attached to a board. Thus, assembly drawing becomes the basis for the mounting of components and programming the automated component placement machinery.

Design for Assembly Handbook

6 Chapters - 50 Pages - 70 Minute ReadWhat's Inside:

- Recommended layout for components

- Common PCB assembly defects

- Factors that impact the cost of the PCB assembly, including:

- Component packages

- Board assembly volumes

Download Now

What should you include in a PCB fabrication drawing?

The details that a fab drawing should include are not exclusive. But there are some important ones in this list that should not be missed. Let us have a look at these specific details.

Board outline to determine the size and form factor

Board outline refers to the external perimeter of your PCB layout. It defines the shape and dimensions of your circuit board. Any fabrication drawing is incomplete without a pictorial representation of the circuit board. This includes all the cut-outs, holes, different radii, and specific distances that are supposed to be in the actual board. All the dimensions are measured from an origin (0,0) point. This origin point on the fab drawing must be the same as that of the (0,0) point on the NC drill data file. The drilled holes are also pointed out in this drawing with symbols linking them to the drill chart.

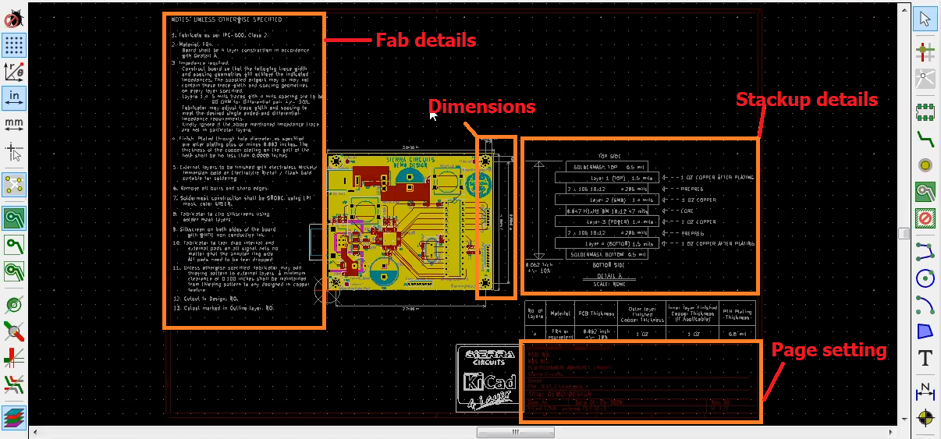

Drill chart to represent plated and non-plated holes

A drill chart demonstrates all the particular symbols assigned to the drilled holes in the board outline. This chart contains information related to the drilled hole requirements of the circuit board to be manufactured. Drill symbols may be shapes or textual characters representing a hole’s position. These symbols are generated by the PCB layout software.

A drill chart features specific symbols with respect to the hole size. This chart also displays details about the number of holes of a particular size, whether they are plated or not, what their hole tolerances are, and so on.

Title block for a clear understanding

Just like any other mechanical/electrical drawing, the title block of a fab drawing will consist of the customer name, part number, revisions, any fabrication number specified, and the measurement units. It is not an absolute requirement for a fabrication drawing, but it is very helpful to have one.

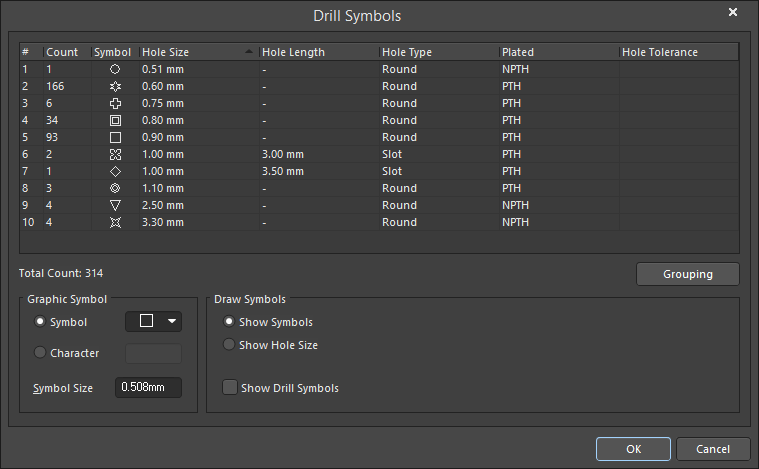

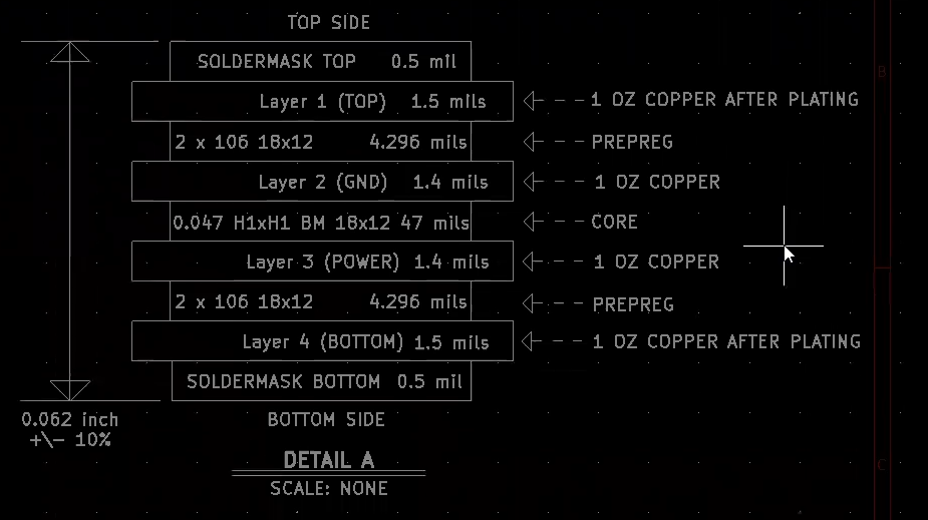

Circuit board layer stack-up

The layer stack-up section of the fabrication drawing will convey information such as layer order, dielectric spacing, copper weight, material type, and the total thickness of the stack-up. The controlled impedance requirements can also be indicated in the layer stack-up. The manufacturer can therefore alter the dielectric constant of the materials, spacing, trace width, etc., to achieve the required impedance.

More PCB fabrication notes for precise manufacturing

Apart from the above must-have information, other details can be included in the fab notes section to ease the manufacturing process.

- Controlled impedance requirements: To achieve the desired controlled impedance, trace thickness, trace width, trace distance from the reference planes, and dielectric constant should be varied accordingly. Any basic impedance calculator can be used for this.

- Board manufacturing specifications.

- Designation of the board’s primary side.

- Raw material specification for the boards: These should meet all the required standards.

- Plating details.

- Solder mask and associated specifications (color, finish, etc.)

- Surface finish: If the surface finish is not mentioned in particular, then ENIG is applied on the board.

- Gold fingers: If gold fingers are a part of the circuit board construction, they can be optionally mentioned in the fab drawing.

- All the critical mechanical specifications related to the hole position.

- Presence of via-in-pad/plugged via.

- Implementation of blind/buried via.

- Tolerances:

- Board tolerance (typically ±10%).

- Etching and plating tolerance.

How to create a fab drawing in Eagle EDA

Easily applicable graphical layout editor (EAGLE) is one of the most used software for PCB design. Generation of fab drawings in Eagle is simple and requires only a few steps. Once the design of the schematic is completed and the layout of the circuit board is ready with all the signals routed properly, then:

- Go to CAM Processor > GerberAuto. This will generate the Gerber file.

- Open Layout editor > Options/Set/Drill. This will allow you to use various drill symbols on the board. Once it is done, the file can be saved in Excellon format. This file will be used as the drill file for fabrication drawing.

- Thus, all the information about the board material and the number of layers can be compiled.

- All of the above files can be sent to the manufacturer as fabrication drawings.

How to generate a fab drawing in KiCad

In KiCad, first, you need to add the title block.

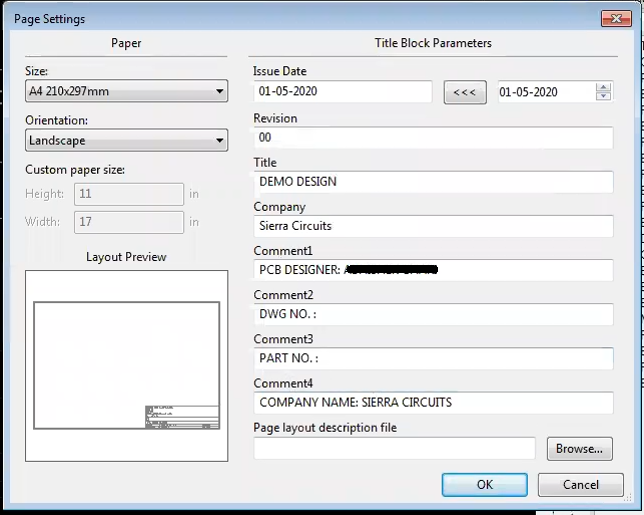

- Go to Files > Page settings. In the window that opens up, add all the details, such as title, company name, part numbers, etc., that need to appear in the title block.

- If you need to include text and logo of the company in the drawing, select the Silkscreen layer > Text icon > and click on the board where the text needs to be added.

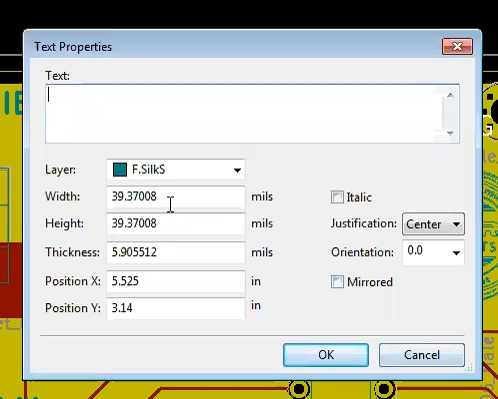

- A window will pop up where the text can be added and customized.

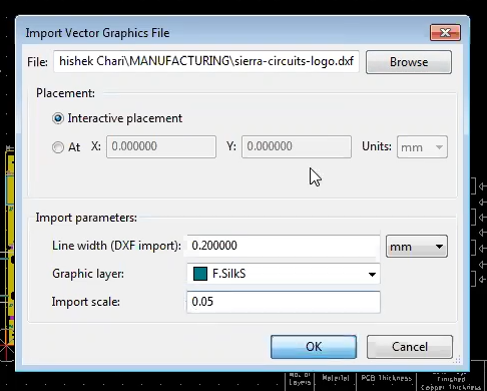

Text properties window in KiCad. - For placing the logo, select Files > Import > Import Graphics.

- Make sure you have the DXF file of the logo. Next, choose the DXF file and set the required dimensions.

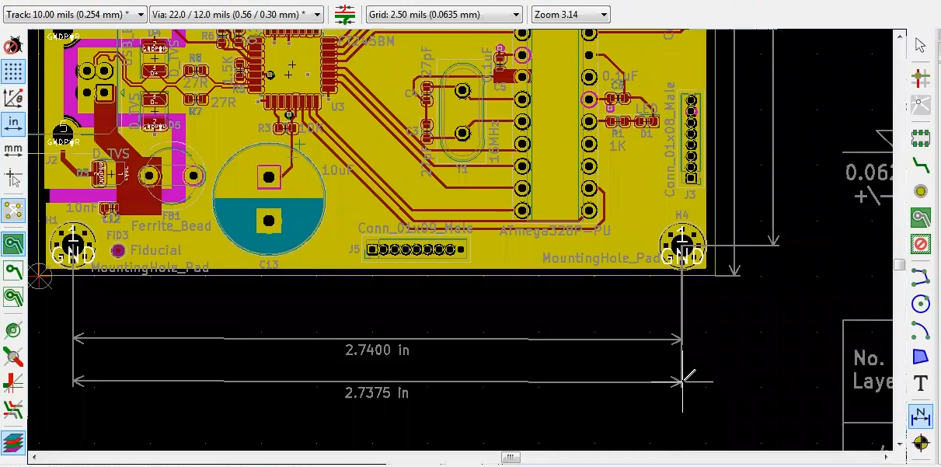

- The next step is to add all the board dimensions in the outline. Click on the Add dimension icon > Fab layer.

- Now, if you have to add the dimensions between two mounting holes, go to the center of the mounting hole. A circle will appear when the cursor is at the center. Click on that and then go to the next mounting hole and pull the dimension down. This will generate a line showing the distance between the two holes.

- Once dimensions are added, the graphics tool draws the stack-up in the fab layer. All the information, such as the layer thickness, solder mask thickness (top and bottom layer), board thickness, tolerances, etc., can be mentioned.

- The text tool can be used to mark the details mentioned above.

- On the fabrication layer, all the fab details can be added. These include the IPC class of the board, number of layers, the solder mask color, and so on. The type of pads (plated or non-plated through-hole pads) and their tolerances can also be mentioned.

Also read how to set up design rules in KiCad.

How to create and save a PCB fab drawing in Altium Designer

To create and save a fabrication drawing in Altium Designer, first, use a blank drawing format of the board and then add all the additional information. Next, fab notes and drill charts can be added. The fab notes are composed or imported from a certain existing file. And drill tables are easily obtained from the steps below:

- Go to Place > Drill table. The drill table will be attached to the cursor, select a location outside the board layout, and press Enter to place it.

- To change the properties of the table before placement, press the Tab key and select the Drill table mode in the properties panel.

All the files added in the fabrication drawing are automatically linked to the design database of the tool. This helps in the automatic update of the drawing corresponding to the changes in the design.

To learn about Gerber generation, read how to export Gerber and production files in Altium Designer.

Fabrication drawings provide additional information that a Gerber file cannot convey to the manufacturer. There are no established standards or formats available for these drawings. It is important that all the required information, as explained above, is included so that there will not be any misinterpretations.

For further clarifications, reach out to us in the comments below, and do let us know what you would like to see more on our website.

Design for Manufacturing Handbook

10 Chapters - 40 Pages - 45 Minute ReadWhat's Inside:

- Annular rings: avoid drill breakouts

- Vias: optimize your design

- Trace width and space: follow the best practices

- Solder mask and silkscreen: get the must-knows