Related Categories — PCB Assembly » PCB Technologies

PCB Procurement Checklist for Hardware Engineers

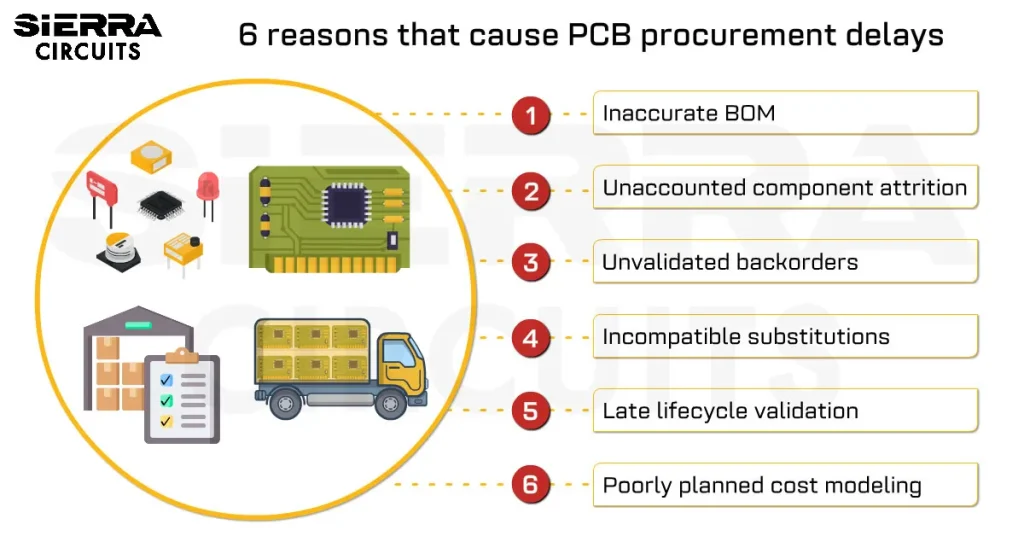

When procuring PCBs, engineering and sourcing teams should follow a structured checklist that validates BOM accuracy and assesses fabricator capabilities. […]

Manufacturing

How to Design an HDI PCB Stack-up

When designing an HDI PCB stack-up, you need to choose the right build-up architecture and define a via ... more »

HDI / Blind & Buried Vias

How to Select and Place RF Components for PCB Designs

Choosing the right RF PCB components and placing them appropriately helps you avoid critical issues such as insertion ... more »

PCB Assembly

PCB Procurement Checklist for Hardware Engineers

When procuring PCBs, engineering and sourcing teams should follow a structured checklist that validates BOM accuracy and assesses ... more »

Manufacturing

How to Design an HDI PCB Stack-up

When designing an HDI PCB stack-up, you need to choose the right build-up architecture and define a via ... more »

HDI / Blind & Buried Vias

How to Select and Place RF Components for PCB Designs

Choosing the right RF PCB components and placing them appropriately helps you avoid critical issues such as insertion ... more »

PCB Assembly

What Are QFN Packages?

The surface-mount IC packages that are assembled on a PCB are available in different types. The most popular ... more »

PCB Assembly

How to Design Reliable Microvias in Your PCBs

Key design strategies for enhancing microvia reliability include selecting suitable materials for laser drilling, adhering to IPC-T-50M guidelines, ... more »

HDI / Blind & Buried Vias

How to Pick the Right Flex PCB Materials for Your Application?

When selecting flex PCB materials, you need to consider the application type (dynamic or static), stiffener requirements, and ... more »

Flex PCBs

PCB Solder Mask Clearance Every Engineer Should Know

PCB solder mask clearance is the space between a copper pad and the surrounding solder resist. It typically ... more »

PCB Design

Why Choose Halogen-Free PCBs for Sustainable Electronics

Halogen-free PCB materials are eco-friendly dielectrics that eliminate hazardous toxins while meeting sustainability standards without compromising performance. Halogen-based ... more »

PCB Manufacturing

How Flying Probe Testing Works for PCB Assembly

In-circuit testing tests the workings of a PCB assembly, i.e., white box testing. Here, we use electric probes ... more »

PCB Assembly

Fabrication, Procurement, & Assembly. PCBs fully assembled in as fast as 5 days.

- Bundled together in an entirely-online process

- Reviewed and tested by Engineers

- DFA & DFM Checks on every order

- Shipped from Silicon Valley in as fast as 5 days

Fabrication. Procurement & Assembly optional. Flexible and transparent for advanced creators.

- Rigid PCBs, built to IPC-6012 Class 2 Specs

- 2 mil (0.002″) trace / space

- DFM Checks on every order

- 24-hour turn-times available

Complex technology, with a dedicated CAM Engineer. Stack-up assistance included.

- Complex PCB requirements

- Mil-Spec & Class 3 with HDI Features

- Blind & Buried Vias

- Flex & Rigid-Flex boards