Related Categories — PCB Design

The Importance of PCB Line Spacing, Creepage, and Clearance

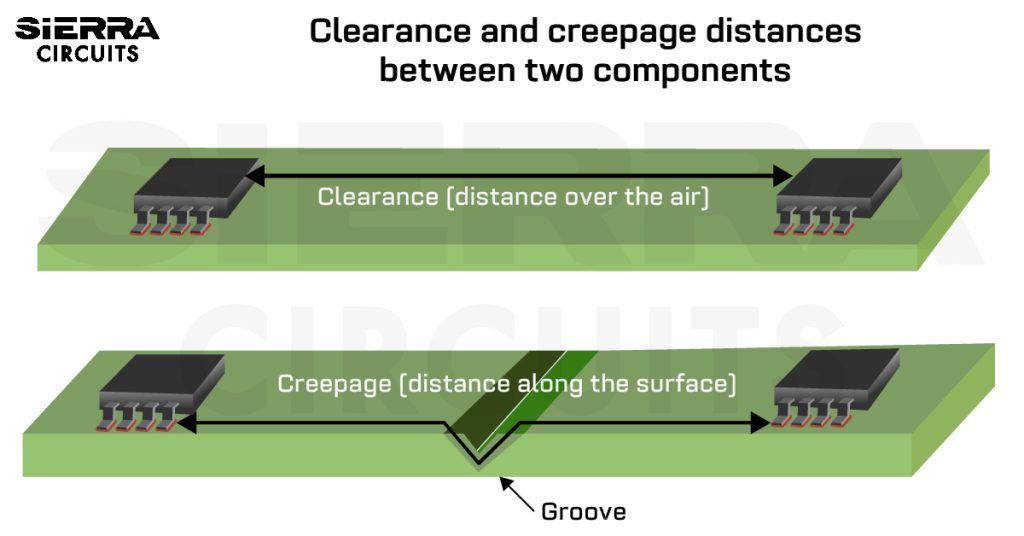

The PCB line spacing for creepage and clearance becomes an important factor from a product safety viewpoint when the standard operating voltage is above 30VAC or 60VDC. Voltages above these levels are considered hazardous, and that is why these designs are regarded as high voltage.

High Current

Case Study: Designing Microcontroller and Functional PCBs with an Antenna

We recently worked on a PCB design comprising 2 modules. Module 1 has a microcontroller, and module 2 ... more »

High Speed

S-parameters Measurement Using a Vector Network Analyzer

Designing a board for operating frequencies higher than a few hundred MHz becomes challenging as it is difficult ... more »

PCB Design

The Importance of PCB Line Spacing, Creepage, and Clearance

The PCB line spacing for creepage and clearance becomes an important factor from a product safety viewpoint when ... more »

High Current

Case Study: Designing Microcontroller and Functional PCBs with an Antenna

We recently worked on a PCB design comprising 2 modules. Module 1 has a microcontroller, and module 2 ... more »

High Speed

S-parameters Measurement Using a Vector Network Analyzer

Designing a board for operating frequencies higher than a few hundred MHz becomes challenging as it is difficult ... more »

PCB Design

Top 5 HDI PCB Routing Challenges and Ways to Mitigate Them

HDI designs pose complex routing challenges due to their tight spacing between components and traces. Using DRC settings in ... more »

HDI / Blind & Buried Vias

How to Determine the Impedance of a Circuit?

Impedance impacts how signals propagate through the board, how power is exchanged between components, and how signals leak ... more »

Controlled Impedance

How to Reduce Ringing in Your PCB Designs

PCB ringing is an unwanted oscillation of voltage or current in a circuit board. During the signal transition ... more »

PCB Design

IoT PCBs: Design Challenges and Emerging Trends by Ethan Pierce

Ethan Pierce, Director of Hardware Engineering at Pierce Design, offered valuable insights into the evolving trends and IoT ... more »

PCB Design

How to Optimize Your PCB Designs for Testing by Harry Kennedy

Harry Kennedy, an electrical engineer and technical specialist at Altair, has shared his expertise in optimizing PCB designs ... more »

PCB Design

How to Handle Crosstalk in High-Speed PCB Designs

Signal integrity measurements have become a critical step in the process of developing digital systems. Signal integrity problems ... more »

High Speed

Fabrication, Procurement, & Assembly. PCBs fully assembled in as fast as 5 days.

- Bundled together in an entirely-online process

- Reviewed and tested by Engineers

- DFA & DFM Checks on every order

- Shipped from Silicon Valley in as fast as 5 days

Fabrication. Procurement & Assembly optional. Flexible and transparent for advanced creators.

- Rigid PCBs, built to IPC-6012 Class 2 Specs

- 2 mil (0.002″) trace / space

- DFM Checks on every order

- 24-hour turn-times available

Complex technology, with a dedicated CAM Engineer. Stack-up assistance included.

- Complex PCB requirements

- Mil-Spec & Class 3 with HDI Features

- Blind & Buried Vias

- Flex & Rigid-Flex boards