Sierra Circuits can deliver your PCBs with -/+ 5% impedance tolerance. We manufacture and assemble high-frequency PCBs without signal distortion. Learn more about how our experts can help you.

Influencing Impedance

What influences impedance in PCBs?

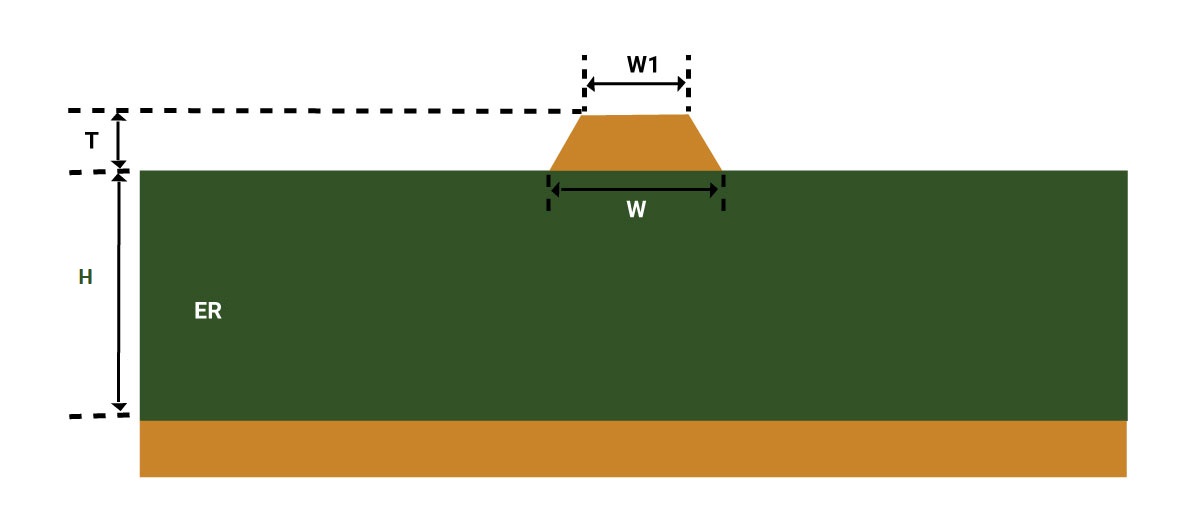

Factors that influence impedance PCB tolerances include materials’ resin content and tolerance, and trace height and width at the top and bottom of the board.

Our controlled impedance tips will help you with your design.

What happens if an actual calculation of trace impedance deviates from the Altium calculated value?

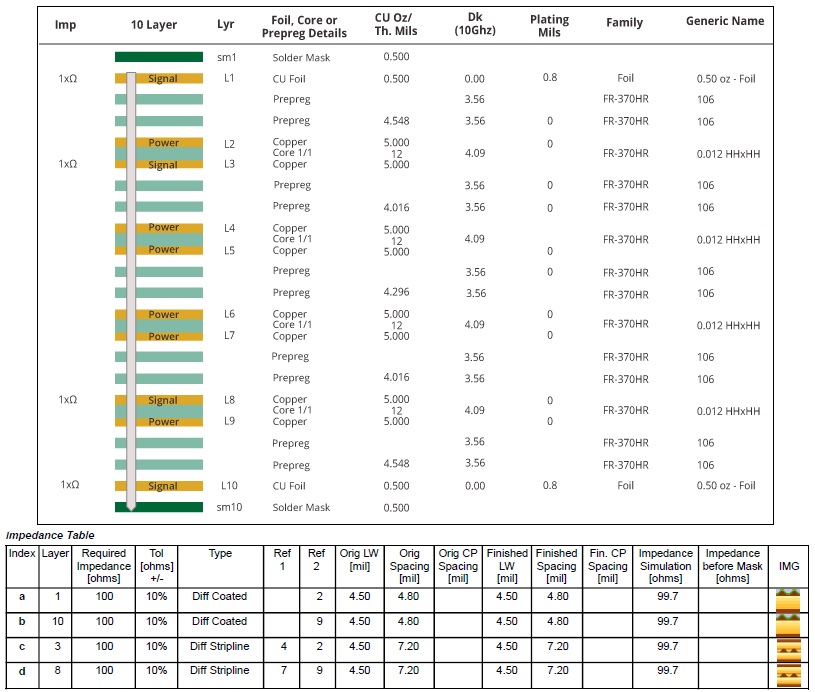

It is always better to ask for a preliminary stack-up. Sometimes you may calculate impedance in Altium or other software, but we may have to change the trace spacing and width. IPC allows +/-1 mil deviation without customer approval. Beyond that, we have to send client stack-up along with impedance calculation.

Material Selection

How do I pick the thickness of the material?

When it comes to choosing materials, keep in mind that we calculate the final press-out thickness that we expect from the prepreg. This depends on the amount of resin in the prepreg, the amount of the copper area percentage, and the thickness of the adjoining copper layers. Since we follow our own press-out thicknesses and not the ones on the data sheets, it can vary from design to design. We might need to adjust the traces and spaces of your initial stack-up to meet your required impedance.

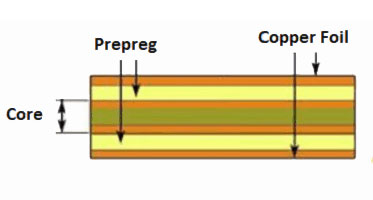

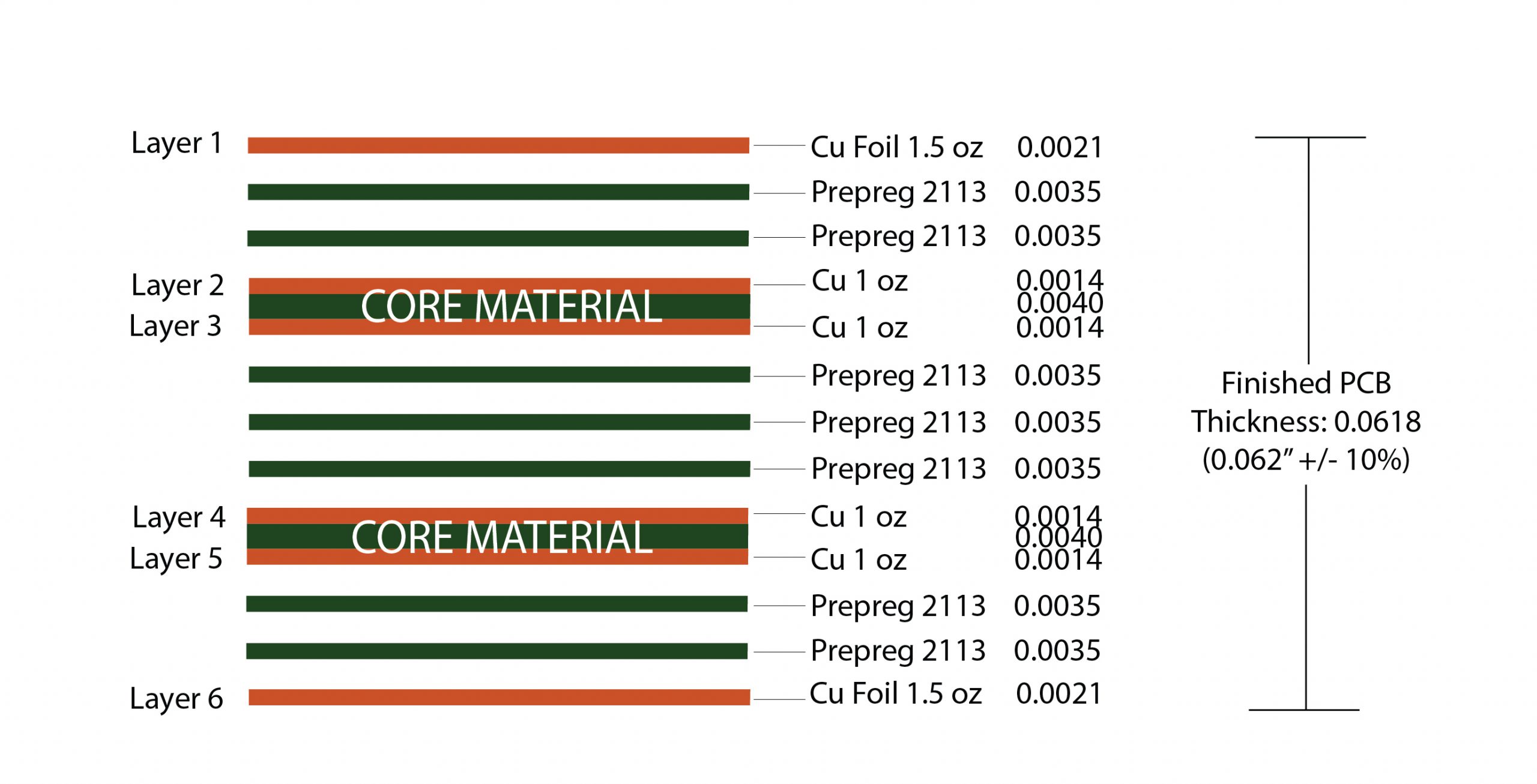

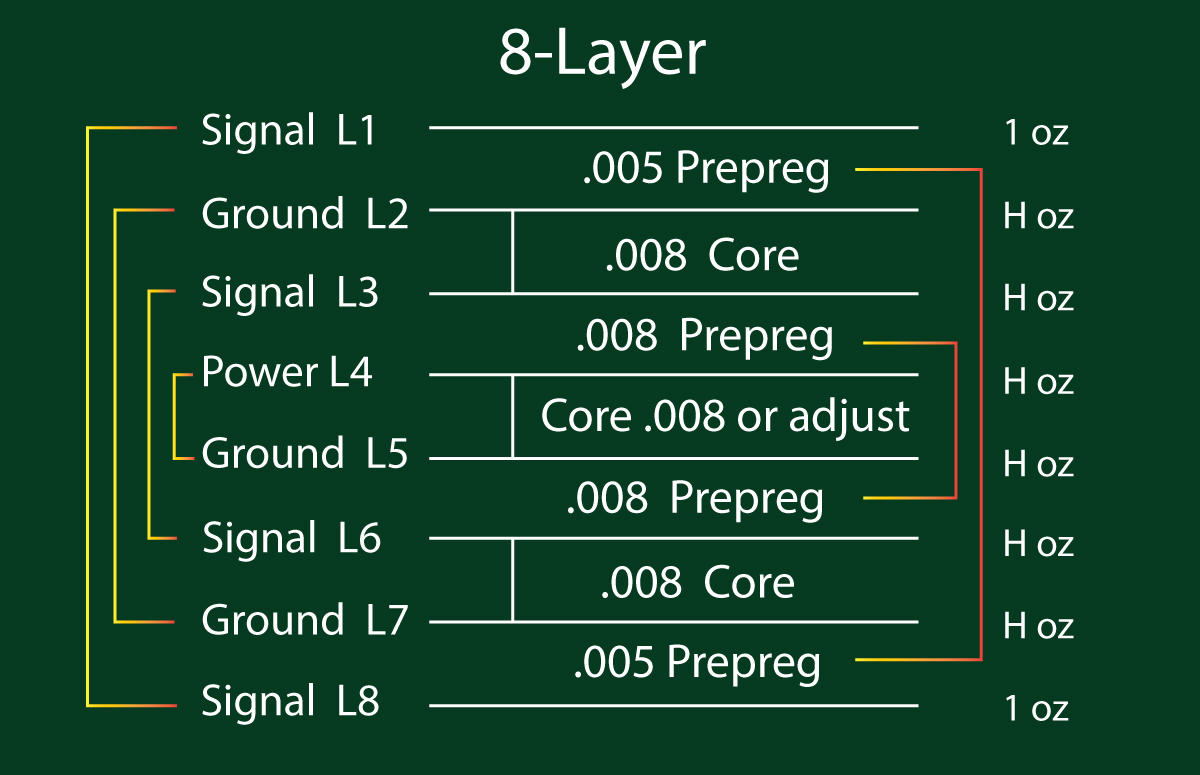

Should I go with a core or a foil construction?

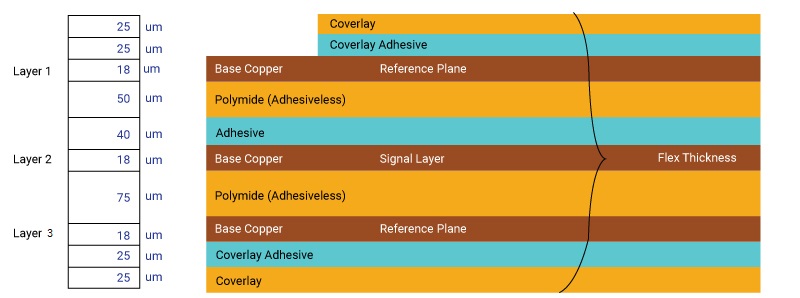

It depends on where in your stack-up you want to place your controlled impedance traces. Since the copper is on the outside of a core, there is not much variation in the dielectric thickness after lamination. However, if you use prepreg for the dielectric thickness, the height varies based on the copper area, the height of the copper, and the glass styles that we have chosen at the time of planning the build.

Stack-Up

Can I get help with my stack-up?

Our engineering support and our stack-up team provide valuable suggestions with their knowledge of controlled impedance for high-speed designs, analog/digital, high density PCB manufacturing design rules and design for assembly rules. Upload your data and receive a free consultation and review of your design. Services include system level design, schematic capture, PCB layout, and PCB/PCBA DFM.

What if I only specify the controlled dielectric?

You can give us your controlled dielectric stack-up, and we will make sure to follow the controlled dielectric thicknesses. However, impedance traces are not specified thus, manufacturing focus is completely upon building a board within +/- 10% tolerance of the specified dielectric thickness from layer to layer.

Is a symmetrical stack-up absolutely necessary in terms of cores and prepregs?

It is decided based on the dimensions or size of the board. Asymmetrical stack-up is perfectly fine for smaller boards and symmetrical stack-up is preferred for bigger boards.

Prepregs

How many different types of prepregs can I use?

It is recommended to not use more than three different types of prepregs in a stack-up. Try to avoid using prepregs that have very low resin and high glass content: very low resin content may lead to resin starvation during lamination.

Impedance Tolerance

How much impedance tolerance can you deliver?

The standard impedance tolerance is 15%. Sierra Circuits delivers 10%, and even 5% if you communicate with us at the very first stage of the designing phase.