Sierra Circuits is proud to serve those who serve. That’s why every mil-spec PCB we manufacture receives priority scheduling for fast-track production. Learn more about our experience designing PCBs for the military and aerospace industry.

PCB Certifications

What industry certifications does Sierra Circuits have to manufacture mil-spec PCBs?

Sierra Circuits has the following industry certifications:

- ISO 9001:2015 Certificate

- ISO 13485:2016 Certificate

- AS9100

- UL Certified

- IPC-A-600 Inspectors

- Defense Logistics Agency (DLA) Approval Letter

- IPC Manufacturers Qualification Profile (MQP) for Sierra Circuits, Sunnyvale, California

- ITAR Registration Letter

- Minority Business Certification

- MIL-PRF-31032 Certificate

- Mil-PRF-55110 Certificate for GF Materials

- Mil-PRF-55110 Certificate for GI Materials

- RoHS / REACH Compliance Material Composition Declaration

- Conflict Minerals Reporting Template

For more information about our certifications, click here.

What are the key differences between ITAR and non-ITAR compliance in terms of lead time and costs?

ITAR compliance typically increases lead times and expenses because it requires all related activities to be conducted within the United States.

Documentation

What documentation is provided with each mil-spec PCB?

We provide all the military-grade documents. The following is the list of documents that we will provide for your mil-spec board:

- Certificate of conformance

- IPC J-STD-001E

- Material specifications

- Record of calibrated tools used during manufacturing

- Reflow profile copy (included with first article)

- AOI report or visual inspection report

- Photo requirements

- Flying probe or in-circuit testing report

- First article inspection report

- Ionic cleanliness test report

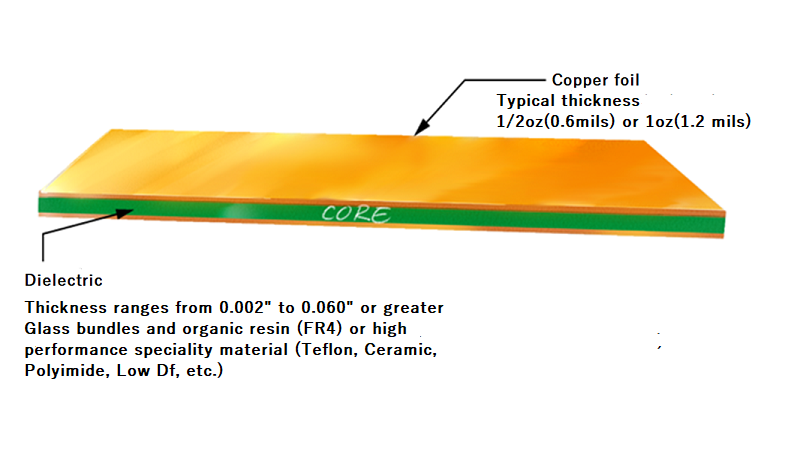

Dielectric and copper

What is the minimum dielectric between two planes?

The minimum dielectric between two planes is 3 mils.

When is a circuit board called a heavy copper circuit board?

A PCB is called a heavy copper board if it has copper layers of thickness more than 3 oz.

Annular Rings

What is the minimum annular ring on finished boards?

The minimum annular ring on finished boards is 2 mils.

What are the annular rings for inner and outer layers in the working Gerbers?

In your Gerber files, you should have a minimum annular ring of 6 mils for inner layers and 7 mils for outer layers.

Hole Size

What is the minimum plating inside the hole (PTH)?

The minimum plating inside the hole is 1 mil.