Contents

On-demand webinar

How Good is My Shield? An Introduction to Transfer Impedance and Shielding Effectiveness

by Karen Burnham

Halogen-free PCB materials are eco-friendly dielectrics that eliminate hazardous toxins while meeting sustainability standards without compromising performance. Halogen-based laminates can release toxic fumes during combustion or disposal, but halogen-free alternatives significantly reduce health and environmental risks.

If you’re a PCB designer, product engineer, compliance officer, electrical engineer, or EMS provider planning to introduce a new product, consider choosing halogen-free dielectric materials. This supports both regulatory compliance and sustainability goals. It also helps build brand trust as the electronics industry is transitioning towards eco-friendly products.

Halogen-free materials reduce health and environmental risks. They do this without compromising electrical performance. That makes them a smart choice for future-proofing your product.

Highlights:

- Halogen-free PCBs eliminate chlorine and bromine-based flame retardants, reducing toxic emissions during production, use, and disposal.

- They rely on alternative flame-retardant systems, phosphorus, nitrogen, and inorganic compounds that suppress fires without releasing harmful gases.

- Global standards such as IEC 61249-2-21 and JPCA-ES-01-2003 define strict halogen content limits to ensure environmental and safety compliance.

- Testing methods like IPC-TM-650 and IEC 61189-2 use oxygen bomb combustion and ion chromatography to accurately measure halogen content.

In this article, you’ll learn the fundamentals of halogen-free PCBs and the testing methods fabricators use to detect halogen content in dielectrics, fluxes, and solder pastes.

What are halogen-free PCBs?

Halogen-free PCBs are circuit boards manufactured with materials that contain extremely low levels of halogen elements, mainly chlorine and bromine.

According to standards such as JPCA-ES-01-2003 and IEC 61249-2-21, a printed board is considered halogen-free if:

- Chlorine (Cl) is no more than 0.09% of the board’s total weight (900 ppm)

- Bromine (Br) is no more than 0.09% of the board’s total weight (900 ppm)

- Combined Cl + Br is no more than 0.15% of the board’s total weight (1500 ppm)

Meeting these limits helps reduce harmful emissions during production, operation, and end-of-life disposal, promoting human health and environmental safety.

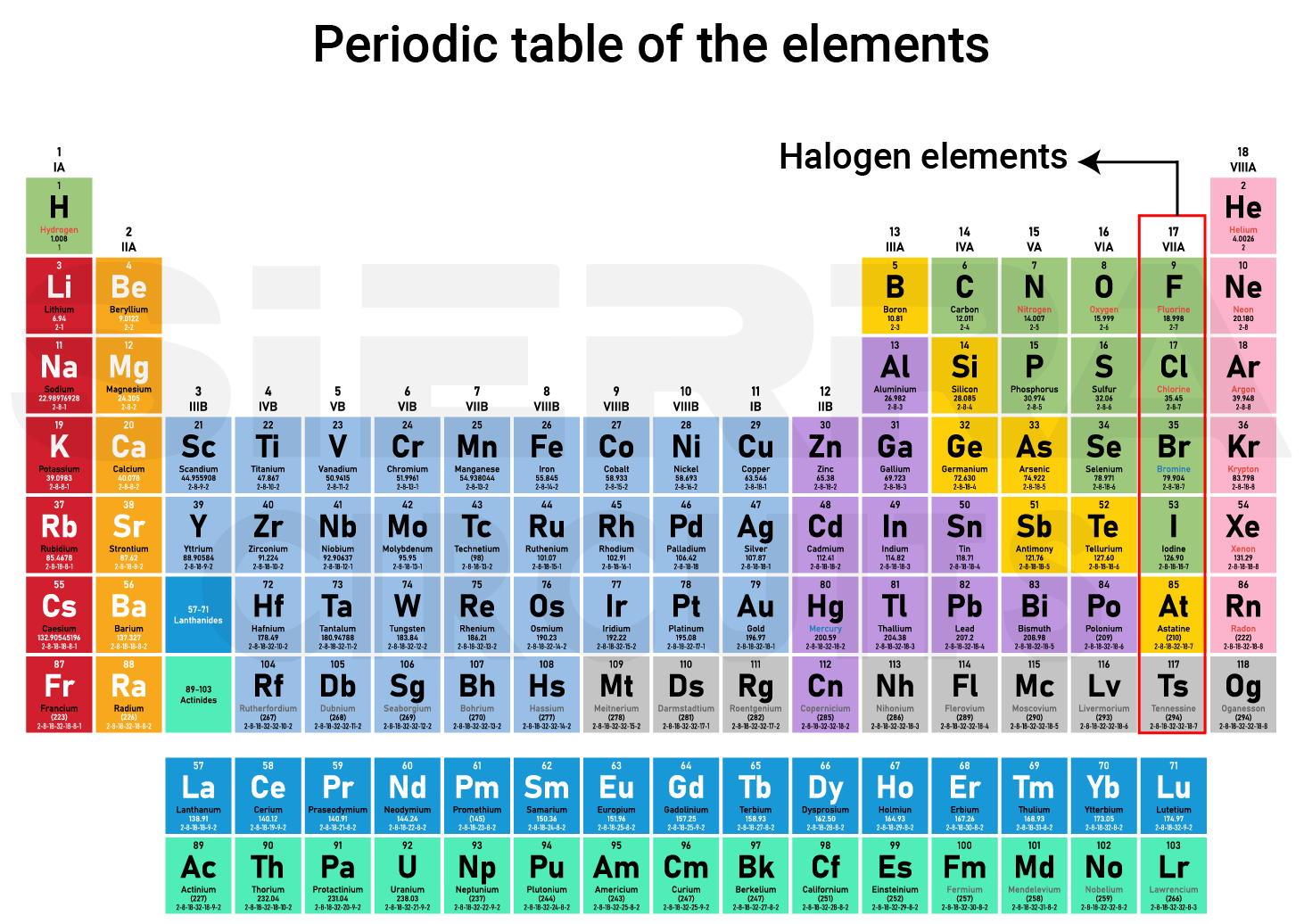

Halogens are a group of elements found in group 17 of the periodic table. This group includes fluorine, chlorine, bromine, iodine, and astatine. These elements are highly reactive and commonly appear in various chemical compounds.

They are generally added to PCB materials to make them flame-retardant. However, these elements can be harmful to health, which has led to a growing preference for halogen-free materials in PCB manufacturing.

Flame retardants are chemical additives that slow or prevent ignition in board materials. They act by disrupting key stages of combustion, such as heating, material breakdown, ignition, and flame propagation.

For more, see why FR4 material is commonly used in PCB fabrication.

What are halides?

Halides are compounds that contain halogen elements like fluorine, chlorine, bromine, or iodine combined with another element. In electronics, halide ions such as chloride (Cl⁻) and bromide (Br⁻) can be found in solder pastes and fluxes.

Ionic halides in flux residues are highly corrosive and hygroscopic (attract moisture), leading to electrochemical migration (dendrite growth) and high leakage currents in PCBs.

These substances are often regulated because they can be harmful to the environment and human health when released, especially during disposal or incineration.

Halogen-free vs. halide-free materials

While halogen-free and halide-free may sound similar, however, there are a few differences.

Halogen-free focuses on limiting the total halogen content in dielectric materials and electronic components to ensure environmental safety and regulatory compliance.

Halide-free, on the other hand, targets flux chemistry and focuses on ionic halides that can cause corrosion and compromise electrical reliability in solder joints.

A flux may be labeled halide-free but still contain non-ionic halogen compounds (like organic bromides) that don’t cause corrosion. This means halide-free doesn’t necessarily mean halogen-free.

If you’re a product engineer or a compliance officer working on eco-friendly products, you should always confirm with the PCB fabricator whether the solder paste is truly halogen-free or only halide-free, as this distinction can impact regulatory compliance.

The table below summarizes the key differences.

| Aspect | Halogen-free | Halide-free |

|---|---|---|

| Composition | Very low levels of halogen elements (Cl, Br, etc.) | Contains very low or no ionic halide content (Cl⁻, Br⁻, etc.) |

| Regulatory standards | IEC 61249, IPC/JEDEC J-STD-709 | J-STD-004C |

| Limit values | <900 ppm Cl, <900 ppm Br, <1500 ppm total | <0.05% total halide ions by weight |

| Test methods | Oxygen bomb combustion + ion chromatography (on residue) | Ion chromatography (on unheated flux) |

| Focus area | Environmental safety and compliance | Electrical reliability, focused on soldering fluxes and pastes |

| Common materials | PCB laminates, solder masks, cables, plastics | Solder fluxes, solder pastes |

| Performance trade-off | May reduce flame retardancy in plastics | Reduced flux activity, narrower process window, poorer wetting |

Download our design guide to learn how to select the right materials for your PCBs.

PCB Material Design Guide

9 Chapters - 30 Pages - 40 Minute ReadWhat's Inside:

- Basic properties of the dielectric material to be considered

- Signal loss in PCB substrates

- Copper foil selection

- Key considerations for choosing PCB materials

Download Now

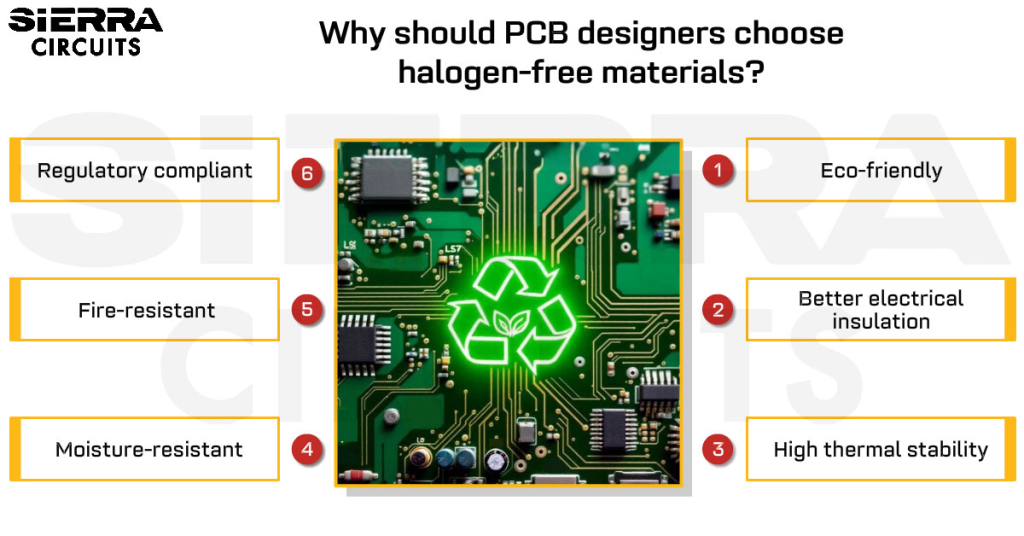

Why should PCB designers choose halogen-free materials?

PCB materials rely on halogens for their flame-retardant properties. However, using these laminates poses serious health, environmental, and regulatory challenges.

Here are 8 reasons why you should choose halogen-free materials:

- No toxic emissions during combustion: Halogen-free laminates prevent the release of harmful compounds like dioxins and benzofurans, which are common byproducts when halogenated flame retardants such as PBB and PBDE burn.

- No hazardous chemical release: Without substances like TBBPA, halogen-free materials eliminate the risk of corrosive fumes such as hydrogen bromide (HBr) during high-temperature operation or disposal.

- Reduced human health risks: These materials minimize exposure to toxins that can cause skin, eye, and respiratory irritation, as well as long-term endocrine or organ damage—protecting workers, end-users, and nearby communities.

- Lower environmental impact: Halogen-free substances degrade more easily and do not persist in landfills or water systems, reducing long-term ecological damage and simplifying e-waste management.

- Regulatory compliance assurance: They meet the strict requirements of directives such as RoHS and WEEE, along with standards like IEC 61249-2-21, helping manufacturers stay compliant in global markets.

- Growing market and industry adoption: Sectors including automotive, telecom, medical, and consumer electronics now favor halogen-free PCBs to meet sustainability goals and customer expectations.

- Stronger branding and sustainability value: Adopting halogen-free materials enhances brand reputation and supports ESG initiatives, while also improving PCB reliability and moisture resistance in dense designs.

- Support from environmental advocacy: Growing awareness and global advocacy for eco-friendly electronics continue to accelerate the shift toward halogen-free manufacturing.

While the shift began due to regulations, manufacturers are also finding that halogen-free PCBs can offer improved performance, making them a smart choice beyond just compliance.

When asked about the transition to halogen-free PCB materials on the SierraConnect forum, Steven Carney, Senior Engineer and R&D Manager at Sierra Circuits, commented:

“There is an increase in the use of halogen-free resin systems, and the industry will probably move more in this direction over time. The selection of halogen-free materials used to be quite limited, but now laminate manufacturers are offering a much broader range of products, so this is a good move. Manufacturers that want to be fully RoHS compliant are specifying halogen-free materials.

Right now, halogen-free laminates are more expensive, estimated at around 15% to 20% higher, but that might come down as their use increases. It shouldn’t affect assembly costs.”

5 challenges manufacturers face when fabricating eco-friendly boards

Transitioning to halogen-free PCBs improves environmental safety and compliance, but it also brings unique technical and manufacturing challenges.

Here are the five most critical issues fabricators must address:

With multiple standards (IEC 61249-2-21, JPCA-ES-01-2003), procurement and compliance teams must carefully verify material certifications.”

- Multiple industry standards, such as IEC 61249-2-21, JPCA-ES-01-2003, IPC-4101B, and J-STD-004, define halogen-free in slightly different ways. Most limit chlorine and bromine content to below 900 ppm each and 1500 ppm combined, but discrepancies across standards cause confusion. The distinction between halide-free and halogen-free further contributes to misclassification and supply chain errors, making it essential for procurement and compliance teams to verify material certifications carefully.

- Halogen-free laminates are more rigid than traditional FR4, increasing drill wear and shortening drill life by as much as 25%. This drives up fabrication costs and forces manufacturers to use higher drilling power. These laminates also have lower resistance to alkaline etching solutions, which means soaking times must be reduced to avoid surface defects such as white spots or delamination.

- Many soldering fluxes marketed as halide-free only exclude ionic halides (Cl⁻, Br⁻) but still contain covalently bonded halogens. Standard ion chromatography fails to detect these compounds, giving a false sense of compliance. The most accurate method is EN 14582 testing, which combines oxygen bomb combustion with ion chromatography to measure all halogen forms.

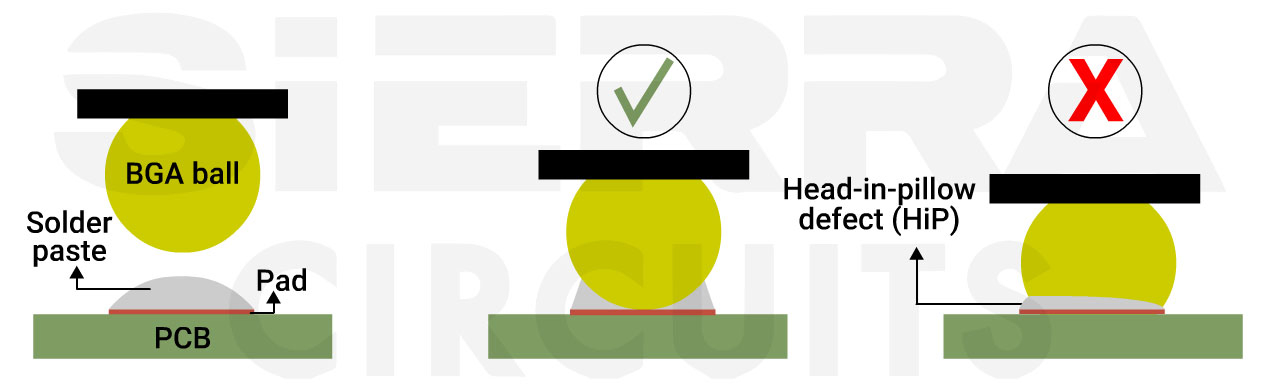

- Eliminating halogens from fluxes and solder pastes can reduce solder wetting and increase the likelihood of defects such as graping (incomplete solder coalescence on small pads) and head-in-pillow (BGA joint failures caused by warpage). These reliability risks require close process monitoring.

Head-in-pillow defect in BGAs. - Halogen-free PCBs, especially when also lead-free, often demand higher reflow temperatures (around 260 °C, about 20 °C higher than traditional leaded processes). This impacts reflow profiles, stencil design, and flux formulation. Achieving stable performance requires careful balancing of solderability, stencil life, print reliability, and shelf life, backed by extensive in-house testing and process refinements.

Sierra Circuits manufactures and assembles high-quality circuit boards with a quick turnaround time. Visit our rigid PCB manufacturing capabilities to learn more.

Industry standards for halogen-free circuit boards

| Standard | Applications |

|---|---|

| J-STD-709 | Electronic products (components, assemblies, e.g., PCBA) |

| J-STD-004B | Soldering fluxes and solder pastes |

| JPCA-ES-01-2003 | PCB base materials/laminates |

| IEC 61249-2-21 | PCB base materials/laminates |

| IPC-4101B | Rigid and multilayer PCB base materials/laminates |

| JEITA ET-7034 / ET-7034A | Soldering materials |

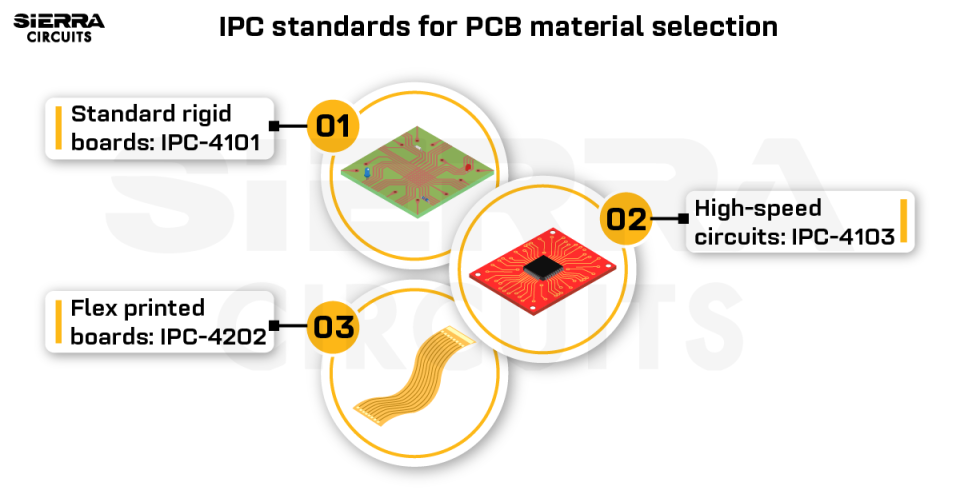

Download our handbook to learn all key IPC standards for PCB design and manufacturing.

IPC Standards Handbook

7 Chapters - 110 Pages - 85 Minute ReadWhat's Inside:

- Clear breakdown of IPC standards for every stage of PCB development

- Design and DFM guidelines based on IPC-2221, IPC-7351, and IPC-J-STD-001

- Material selection guidance tied to IPC-4101, IPC-4202, and more

- Testing and inspection insights using IPC-A-600 and IPC-TM-650

- Best design documentation practices for seamless production

Download Now

Types of flame-retardant materials used in PCBs

To meet both safety and environmental requirements, halogen-free PCBs rely on flame-retardant systems that do not contain chlorine or bromine. Electrical engineers and PCB designers evaluating resin systems should consider how different flame-retardant chemistries affect both thermal stability and processing performance. The most widely used alternatives include:

1. Phosphorus-based flame retardants

Phosphorus compounds are among the most common halogen-free solutions. They suppress flames by creating a carbonized protective layer on the material surface, which insulates the PCB substrate and limits oxygen exposure. Unlike halogenated systems, they do not release harmful fumes.

Example: Ammonium phosphate, widely used in LED lighting and power modules, decomposes into metaphosphoric acid when heated. This promotes the formation of a stable char layer that reduces flame spread.

2. Phosphorus-nitrogen compounds

These materials combine the strengths of phosphorus and nitrogen for dual-action fire resistance. They form a carbon-rich char layer, while also releasing non-flammable nitrogen gases that dilute flammable vapors and suppress combustion intensity.

Common in automotive electronics and industrial control systems, these compounds provide both physical insulation and gas-phase flame inhibition, making them suitable for high-power, thermally demanding applications.

3. Inorganic flame retardants

Inorganic fillers like magnesium hydroxide and aluminum hydroxide act mainly through physical cooling. At high temperatures, they absorb heat and release water vapor from their crystal structure. This vapor lowers the combustion-zone temperature, slowing or halting burning.

These materials are non-toxic, chemically stable, and emit no dangerous fumes during combustion. They often serve as additives in composite systems to enhance flame resistance.

4. High-temperature resin systems

To maintain mechanical and electrical performance under extreme heat, halogen-free PCBs often use specialty resins such as epoxy phenol novolac, bismaleimide (BMI), and dicyandiamide (DCA)-based resins.

These resins deliver excellent thermal stability, mechanical strength, and insulation without halogens. Manufacturers widely use these resins in EV battery management systems, industrial power modules, and high-reliability consumer electronics.

Here are a few examples of halogen-free dielectric materials:

- Panasonic’s R-1566 and Megtron 6

- Rogers’ 92ML

- Ventec’s VT-441

Use our PCB Material Selector to pick the right halogen-free materials for your design.

Testing methods used by the fabricators to determine the halogen content

Manufacturers and compliance teams perform these tests to identify halogen content in dielectrics, flux, and solder paste.

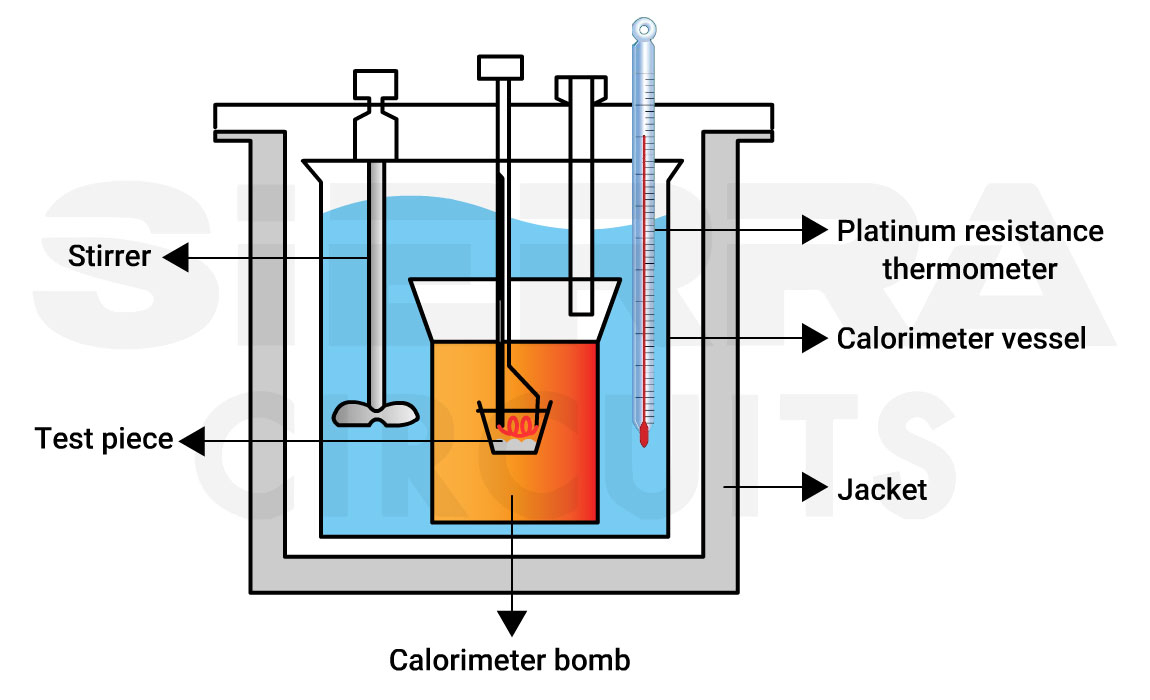

1. IPC-TM-650 2.3.41: Halogen test method in PCB base materials

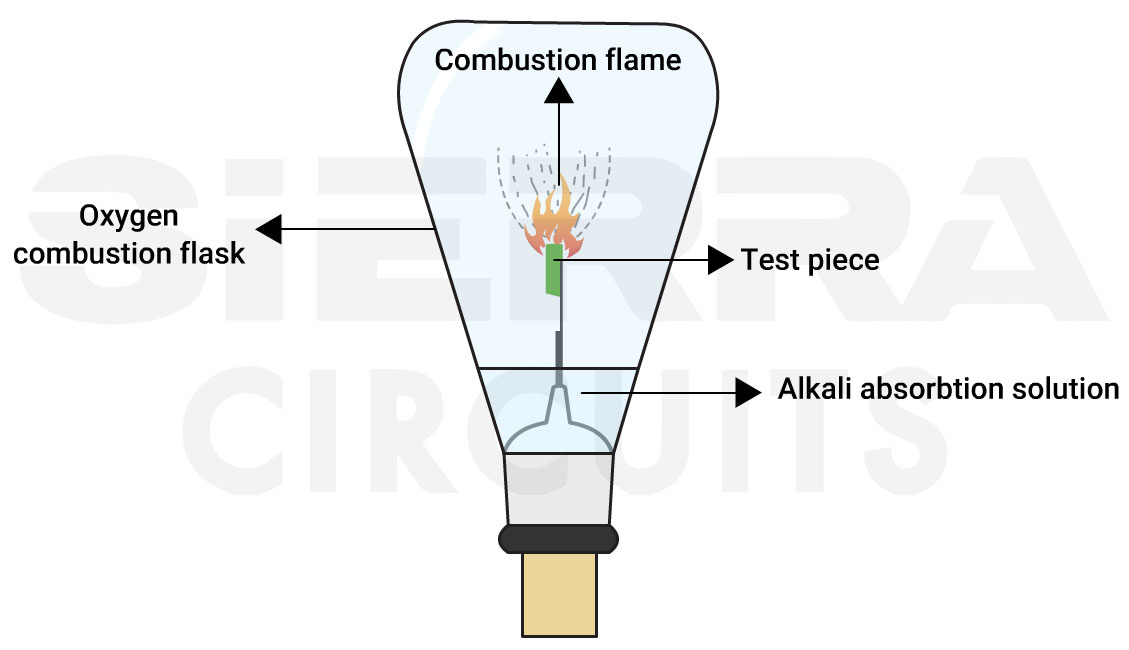

Step-1: The copper foil is first removed, and the cleaned laminate samples are burned in a sealed, oxygen-filled flask. An alkali solution inside the flask captures the combustion gases, converting halogens into measurable halide ions.

Step-2: The solution is then filtered and analyzed with ion exchange chromatography to quantify chlorine and bromine levels.

Step-3: Results are compared against a blank sample and reported in parts per million (ppm), based on the sample’s mass. The test report typically includes chloride, bromide, and total halogen averages across multiple samples, as well as the testing conditions and analyst details for traceability.

2. IEC 61189-2: Halogen test method for fluxes and solder pastes

Step-1: The sample is burned at high temperature in an oxygen bomb, breaking all covalent bonds and volatilizing organic compounds.

Step-2: The remaining ash, which contains halide ions and other inorganics, is dissolved and analyzed via ion chromatography to detect both ionic and formerly bonded halogens.

Step-3: To simulate reflow conditions, thermo-gravimetric analysis (TGA) is performed to calculate how much flux residue remains after soldering. Combining TGA with OBC-IC provides a realistic estimate of halogen levels in the final residue.

Example: If a raw flux contains 450 ppm chloride and TGA shows 50% residue after reflow, the effective chloride concentration in the residue would be ~900 ppm.

Use our tool to quickly check your PCB design files for potential issues.

Pros and cons of halogen-free printed boards

Pros:

- Eco-friendly: Do not release toxic dioxins or corrosive gases during combustion or disposal.

- Better electrical insulation: Phosphorus- and nitrogen-based systems lower polarity, enhancing insulation resistance and shock tolerance.

- High thermal stability: Offers higher Tg, reduced thermal expansion, and is suitable for high-power or high-frequency applications.

- Moisture-resistant: Lower water absorption minimizes corrosion, metal migration, and reliability issues in humid environments.

- Fire-resistant: Generates less toxic smoke and safer emissions during fire events.

- Regulatory compliant: Meet RoHS/WEEE directives and support sustainable product positioning.

Cons:

- Higher costs: Substrates are more expensive, increasing overall manufacturing costs.

- Limited material choices: Fewer laminate and prepreg options restrict design flexibility.

- Higher processing demands: Require elevated reflow and curing temperatures.

- Lower fabrication yield: Processing challenges can lead to more defects and reduced yields.

- Low supplier availability: A limited number of vendors manufacture halogen-free laminates.

- Reduced mechanical durability: Laminates tend to be more brittle and rigid, increasing drill wear and the risk of cracking.

Key takeaways:

- Collaborate early with your fabricator to select the right halogen-free laminate and confirm drilling, reflow, and etching parameters.

- Reassess flux and solder paste chemistry; halide-free does not always mean halogen-free.

- Stay aligned with global standards (RoHS, WEEE, IEC 61249-2-21) to ensure compliance and support sustainability goals.

- View halogen-free design not just as a regulatory requirement, but as a step toward safer, more eco-friendly electronics manufacturing.

The move to halogen-free PCBs is no longer just a compliance exercise; it’s a strategic shift toward safer, cleaner, and more sustainable electronics. Halogen-free materials offer environmental and performance benefits. However, they also present manufacturing challenges.

Need assistance in selecting the right material for your circuit board? Post your queries on our PCB forum, SierraConnect. Our design and manufacturing experts will help you select one.

About Mohamed Faheemuddin : Mohamed Faheemuddin is a mechanical engineer. His passion for electronics drew him to the PCB industry. With an experience of over 3 years in the PCB industry, he specializes in developing articles for engineers and hardware designers.

Start the discussion at sierraconnect.protoexpress.com