Contents

On-demand webinar

How Good is My Shield? An Introduction to Transfer Impedance and Shielding Effectiveness

by Karen Burnham

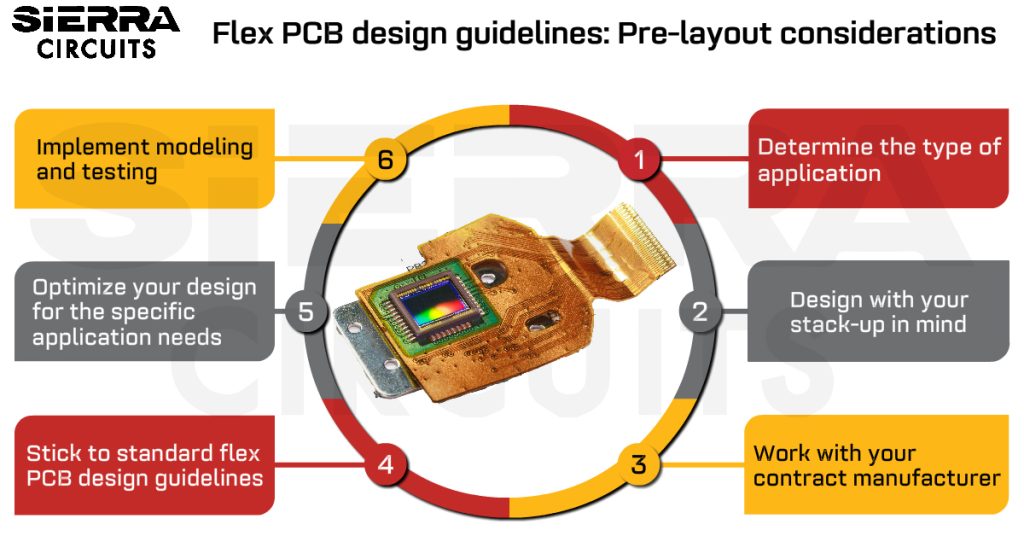

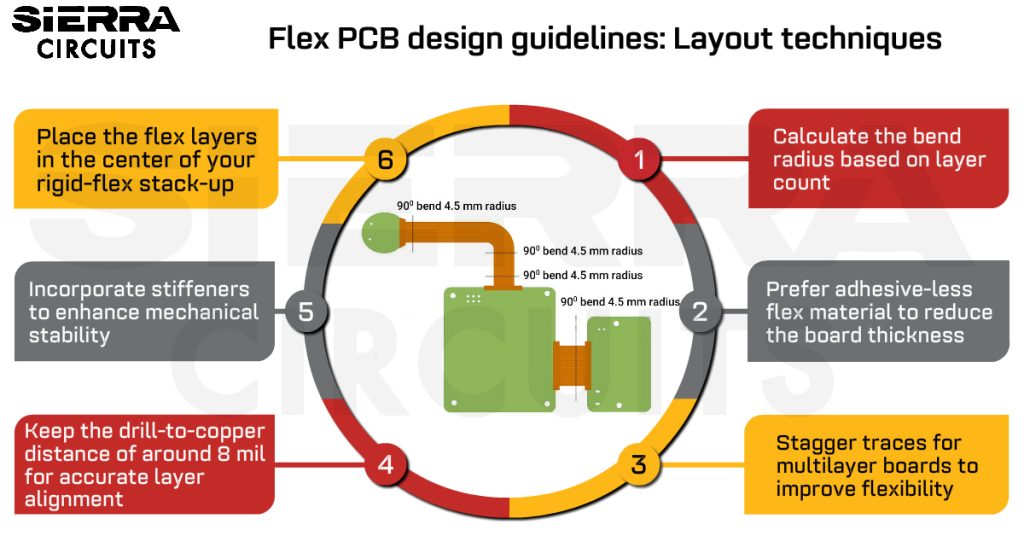

Designing flexible printed circuit boards requires a different approach than traditional rigid boards. Flex PCB pre-layout considerations include determining the type of application, selecting the appropriate bend radius, and working with your contract manufacturer. Understanding these preliminary steps is crucial for creating a flexible board that can handle dynamic or static applications.

Highlights:

- Flexible printed boards provide a reliable interface without external connectors.

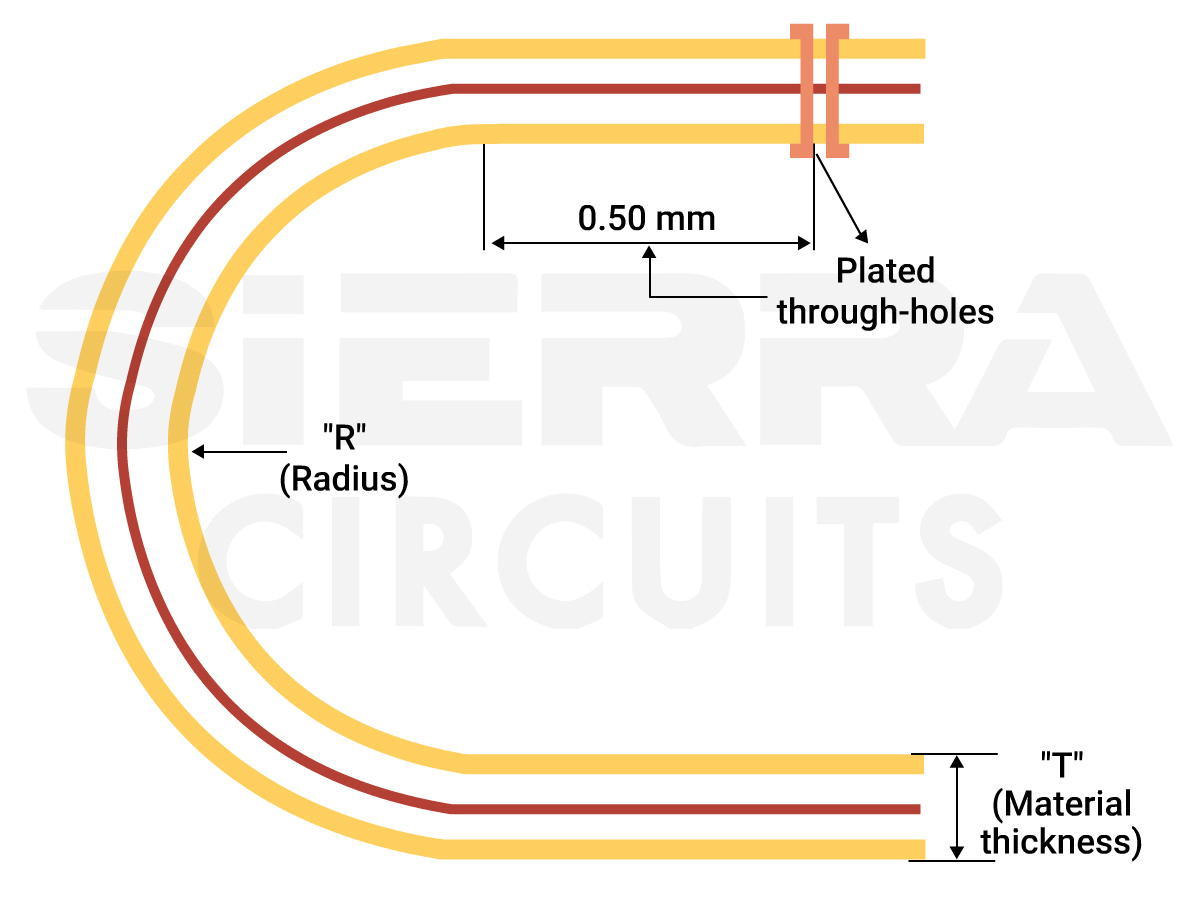

- The material thickness of flex boards varies between 0.5 and 5 mil.

- FPC (flexible printed circuit) reduces potential failure points, allows a range of motion, and enables miniaturization.

In this 2-part blog series, first, we will cover flex PCB pre-layout considerations. In the next blog, flex PCB design guidelines part 2: optimizing layout for manufacturing, we will explore advanced flex layout and routing techniques.

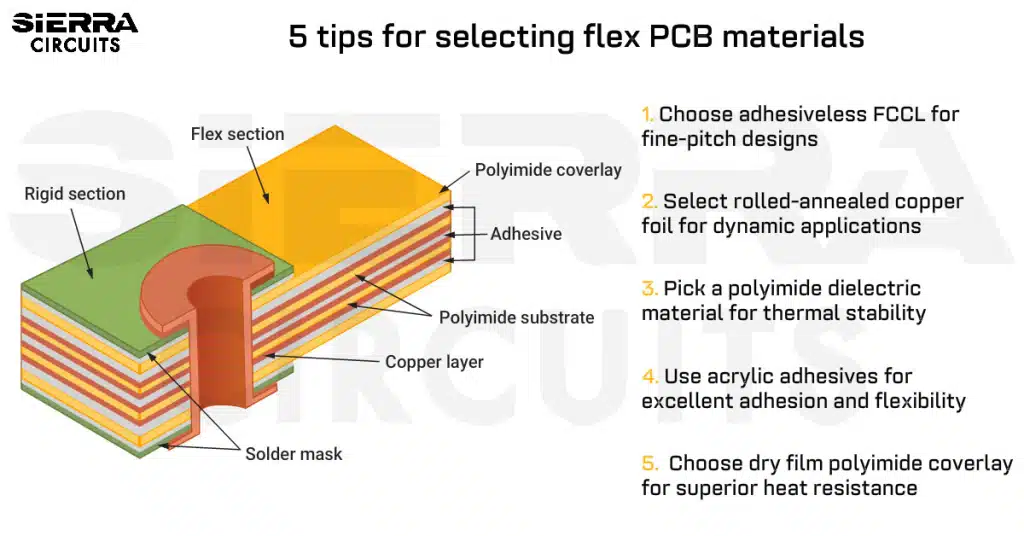

What is a flexible circuit board made of?

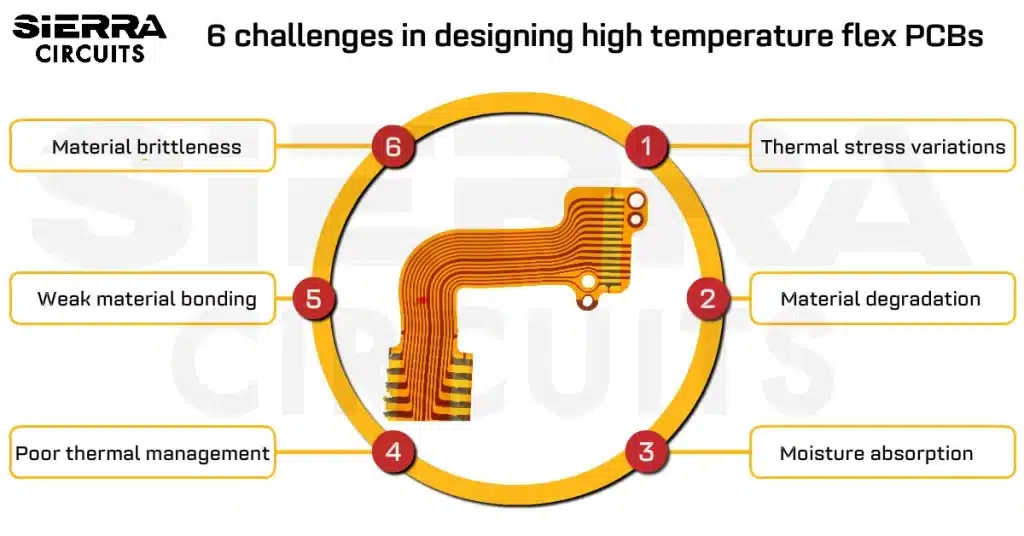

Flex PCBs are built using very thin polyimide substrates. These materials offer excellent mechanical strength and thermal resistance, making them well-suited for high-temperature flex PCBs. They can also be molded into complex three-dimensional shapes for use across a diverse range of applications, such as heads-up displays for aerospace piloting and wearable technology.

These materials have an acrylic base and offer a lower dielectric constant than standard materials. The thickness of the flex PCB materials varies between 0.5 and 5 mil.

For more on polyimide FPC material, see why polyimide PCB material is the right choice for flex designs.

What are FPCs used for?

Medical electronics: Widely used in medical devices due to their compact size and 360° bendability.

Automotive industry: Excellent resistance to vibration makes them ideal for the harsh environment inside a motor vehicle.

Space applications: Most aerospace applications use FPC to reduce the system’s overall weight.

For more on flex circuit board applications, see the history of flexible PCBs and their modern applications.

Flex PCB pre-layout considerations recommended by Vern Solberg

Vern Solberg, a seasoned flex PCB expert with 25+ years in SMT and microelectronics design, outlined a few tips for capitalizing on the inherent advantages of flex printed boards.

Solberg holds multiple patents for IC packaging innovations, including the folded-flex 3D package technology and multiple die designs.

1. Determine the type of application

Before the design stage begins, ensure you know the answers to the following questions:

- How many times will your PCB flex? Will it be a dynamic or static board?

- What is the bend radius?

- How thin or thick can the overall PCB be?

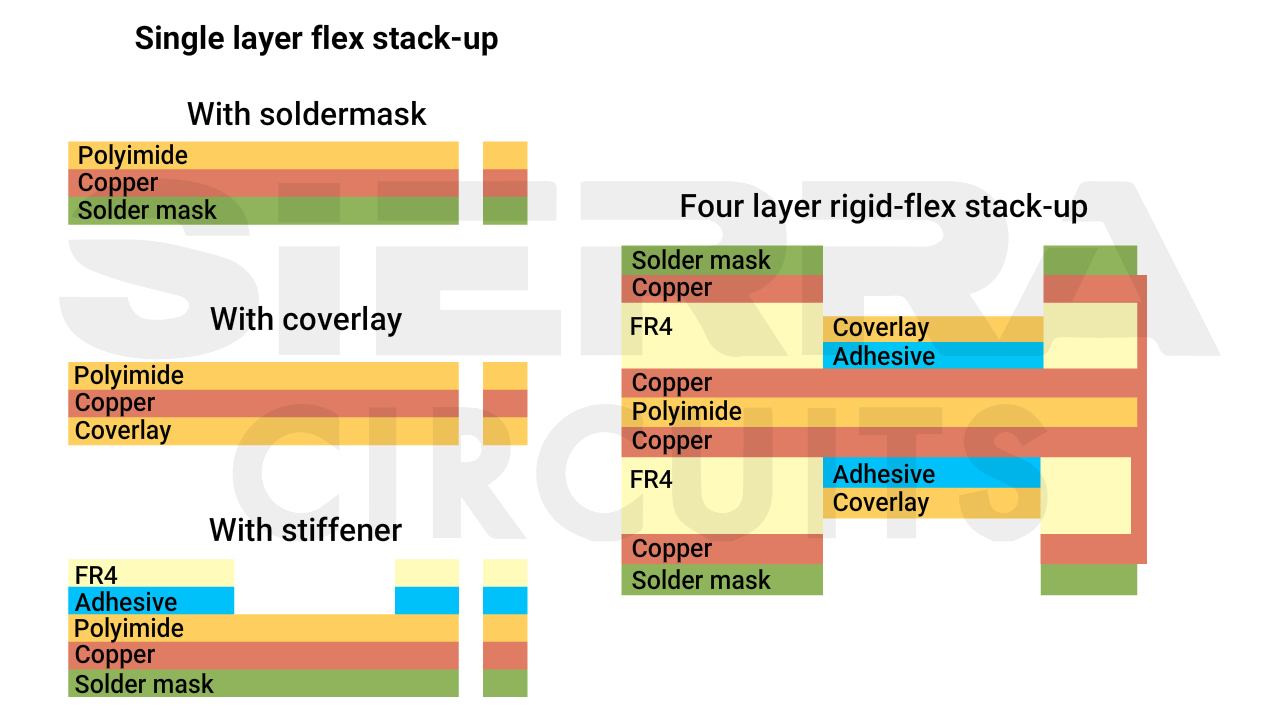

Stack-ups for dynamic and static devices vary, so the application and type of board must be known beforehand.

To learn how to design a reliable flex PCB, download our design guide.

Flex PCB Design Guide

10 Chapters - 39 Pages - 45 Minute ReadWhat's Inside:

- Calculating the bend radius

- Annular ring and via specifications

- Build your flex stack-up

- Controlled impedance for flex

- The fab and drawing requirements

Download Now

2. Design with your stack-up in mind

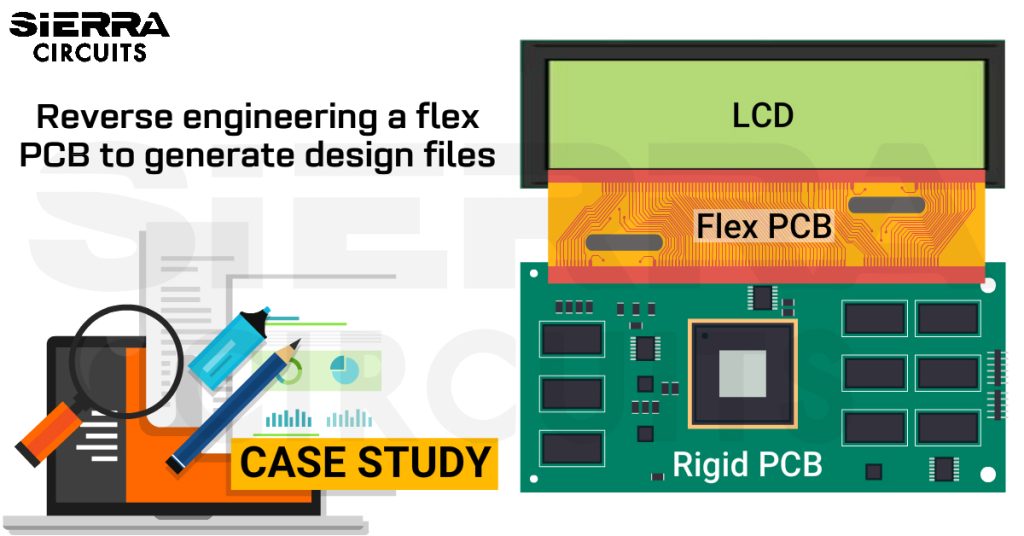

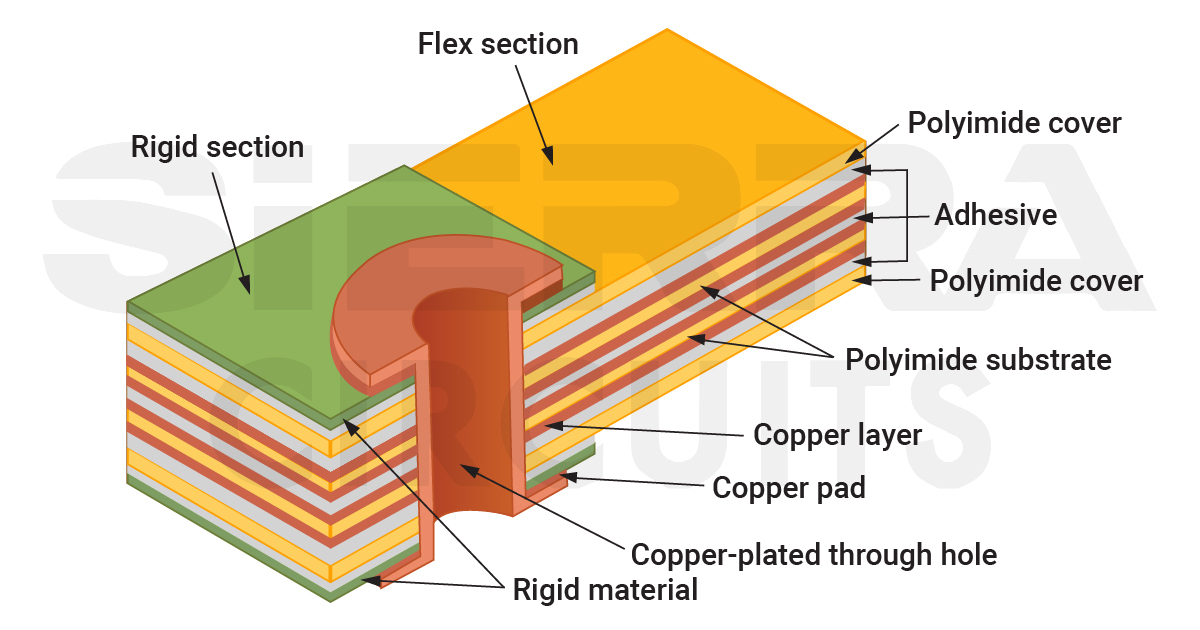

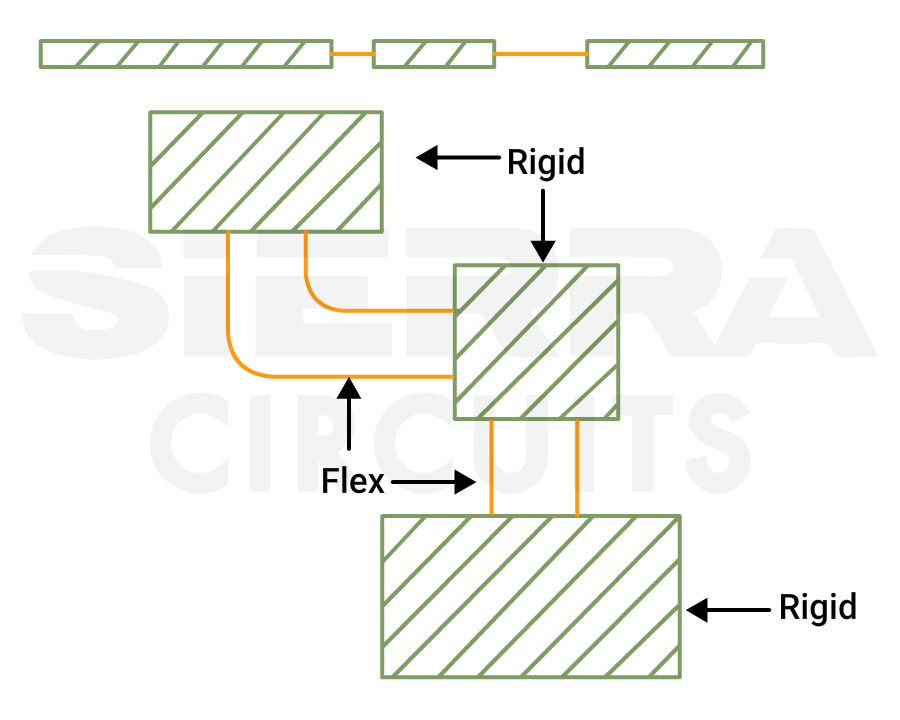

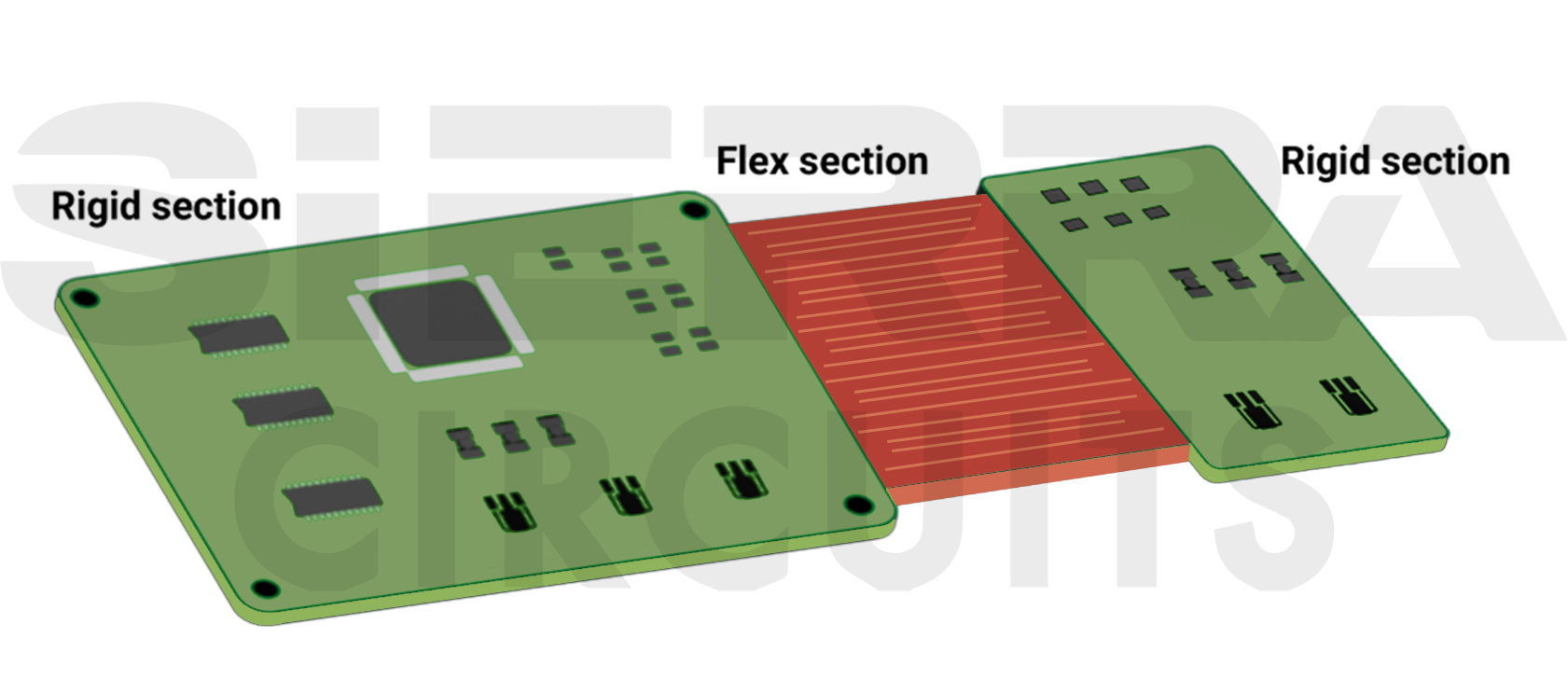

Request a stack-up from your manufacturer. It is crucial that you know how to stack your circuit board layers. Rigid-flex is the simplest configuration that will allow you to reduce the number of connectors, which will also increase wiring density and reliability.

One way to get off to a good start here and avoid rework is to build models early on, using paper or mylar. Primary components can be arranged to ensure proper fit, while rigid sections can be glued.

A face-to-face meeting with your contract manufacturer is the best way to ensure you’re on the same page regarding the overall process. This meeting can also help ensure that design guidelines and capabilities are well understood.

Check our flex and rigid-flex PCB capabilities to learn about our quick-turn FPC services.

3. Consult your contract manufacturer

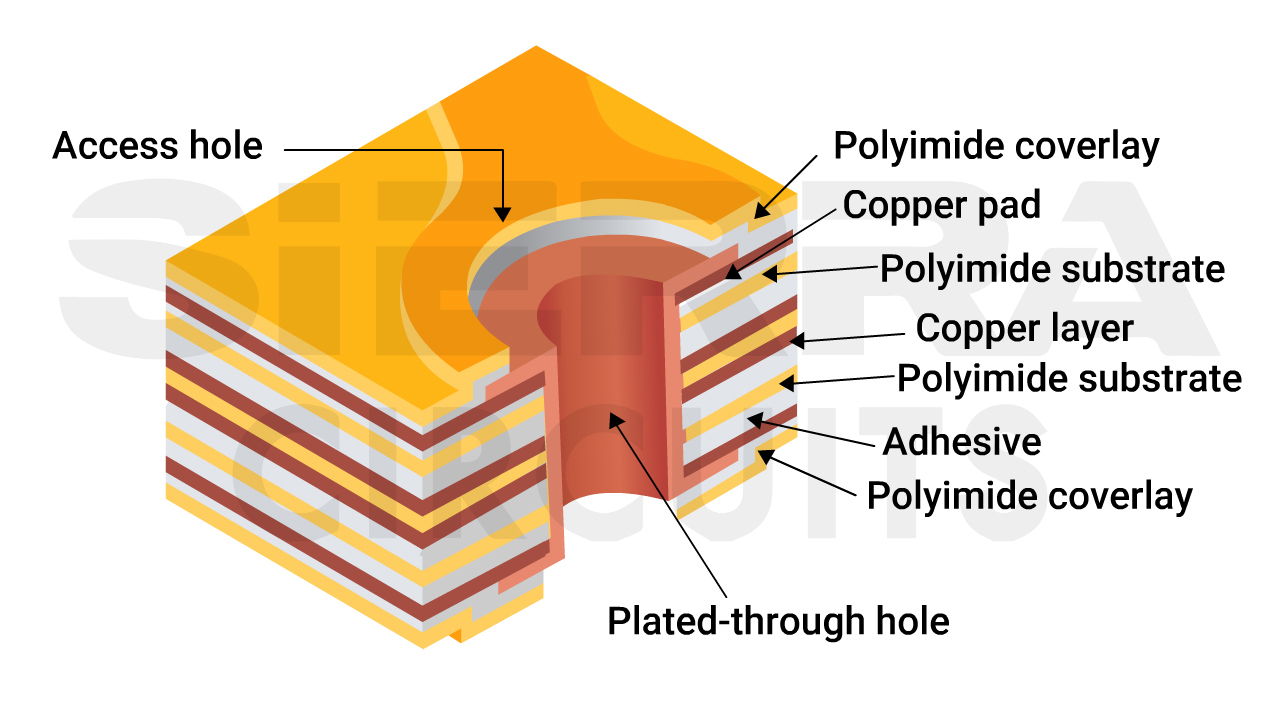

The design rules for flex and rigid-flex are different from standard rigid boards. FPCs require button plating, and annular rings need to be larger than rigid designs. Each contract manufacturer may have their own set of design rules and recommendations.

Always consult your manufacturer before finalizing the materials. The dielectric should be suitable for the environment and the application in which the board will operate.

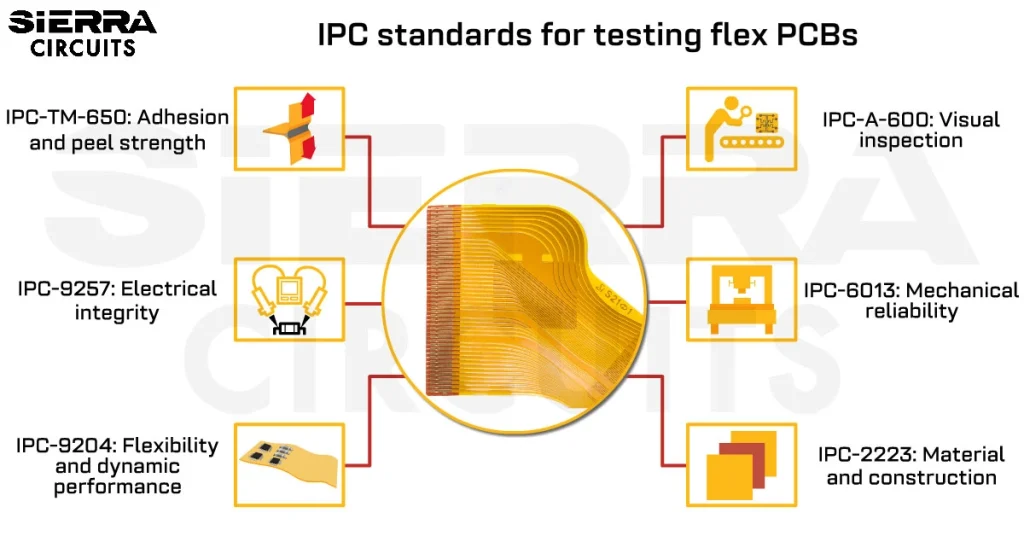

4. Stick to standard flex PCB design guidelines

Follow the standard design rules to cut the overall board cost.

Here’s a list of IPC and mil-grade standards for flex and rigid-flex boards:

| Standards | Description |

|---|---|

| IPC-2223 | Sectional design standard for flexible/rigid-flexible printed boards |

| IPC-4202 | Flexible base dielectrics for use in flexible printed boards |

| IPC-4203 | Cover and bonding material for flexible printed circuitry |

| IPC-4204 | Flexible metal-clad dielectrics for use in fabrication of flexible printed circuit |

| IPC-6013 | Spec for flexible/rigid-flexible printed boards |

| MIL-P-50884 | Military specification: Printed wiring board, flexible or rigid-flex |

Placing your flex layer within your rigid layers is one of the important DFM guidelines you must follow. However, multilayer boards with greater complexity are in demand as pin counts rise and thousands of I/Os are incorporated into some devices.

5. Optimize your design for the specific application needs

Customize the design to align perfectly with the requirements of your application. There is no “one size fits all” approach to flex PCB design.

For example, exploring alternatives like rigid-flex configurations becomes necessary if your application demands more than a single-layer flex. Further, you will need to decide whether to incorporate stiffeners based on the application’s mechanical requirements, size constraints, and budget considerations.

Know your printed circuit board supplier and their capabilities—you don’t want to end up designing a board that can’t be manufactured. Suppliers have their own design rules and recommendations that should be considered.

For rigid-flex DFM guidelines, see 13 common DFM mistakes in rigid-flex PCBs and techniques to avoid them.

6. Implement modeling and testing

Creating a paper doll model before starting the prototyping process is helpful. This pre-layout consideration allows you to refine the design and layout, reducing the need for respins in your prototype. Paper doll models ensure you get your design right the first time.

Solberg explained:

“I have created a number of models simply with a piece of stiff paper, or mylar. I glue rigid and flex sections and put on the primary components. First, I ensure everything fits, and then collaborate with the supplier to choose materials that can withstand the environmental challenges ahead.”

The polyimides used in coverlay are rugged enough to handle most environments. However, issues are more common with laminates, which are less robust under harsh conditions. Laminates are unsuitable for certain chemicals or adhesives, and the vias are liable to crack without reinforcement.

The copper in flex PCBs differs from the copper in rigid boards. Flex materials also do not have glass weave or suffer from material cracking once we drill into them.

For more FPC design tips, see 7 must-knows for your first flex PCB design.

Advantages of flex PCBs

1. Facilitates seamless integration and enhanced functionality

With minimal design constraints, flex boards can be tailored to fit any device shape. This adaptability makes them suitable for a wide range of applications.

Additionally, they minimize the risk of potential failure points typically found in standard PCBAs by eliminating the need for connectors and extra cables. FPCs reduce the product’s overall weight and facilitate miniaturization.

2. Reduces overall board expense

Using flexible printed circuits can result in direct and indirect cost savings.

Direct cost savings

A single rigid-flex board with multiple rigid sections can replace the assembly of multiple circuit boards within a product.

For instance, if a product initially requires 6 rigid boards, a single rigid-flex PCB with 6 rigid sections can be designed to fulfill the same functionality. This consolidation eliminates the need for multiple boards, wire harnesses, and connector pairs. This inventory reduction leads to direct cost savings.

Indirect cost savings

The absence of wire harnesses simplifies the assembly process, reducing labor costs and assembly time. Since flex circuit boards can be designed to incorporate all necessary connections and wiring within the board, assembly manual components (connectors) can be eliminated. This reduces the overall cost of the flex PCB assembly process.

Wiring errors, such as incorrect connections, are common sources of product failures in standard circuit boards. Integrating wiring directly into the FPC significantly reduces the risk of wiring errors. This improves the product’s overall reliability, leading to potential cost savings associated with warranty claims, repairs, and returns.

Also, see rigid-flex assembly for hybrid designs that combine stability with flexibility.

3. Supports static and dynamic applications

Flexible printed circuits can be used in both static and dynamic applications.

FPCs experience minimal to no bending during their operational lifespan in static applications. They are commonly found in consumer electronics like smartphones, tablets, and laptops, where they’re integrated into the device’s structure without experiencing much bending or flexing during normal use.

Conversely, dynamic applications involve circuit boards that are designed to bend during operation. They’re typically found in wearable devices, automotive systems, printers, and humanoid robotics.

4. Eliminates the requirement of bulky connectors

Traditional connectors are susceptible to mechanical wear and damage over time, especially in applications subject to vibration or movement. Hence, by eliminating these connectors, flex PCBs reduce the number of potential points of failure, resulting in improved reliability and longevity of the product.

Vern Solberg explained in an interview:

“We use flex because we need a good, rugged, dependable interface. Wire cables are not always dependable, but flex is. At other times, it is because of the shape or the need to fit the product into a small space, and their flex allows us to connect two rigid boards in a very small space.”

Key takeaways:

- Flex PCBs can be static or dynamic based on bending capabilities.

- Flex circuits can be used for medical, automotive, and space applications.

- Determine the type of application, bend radius, and overall thickness in the initial stage of the design.

- Rigid-flex configuration reduces connectors and increases wiring density.

- Always follow the IPC standards such as IPC- 2223, 4203, 4204, 4205, and 6013.

- Consult your CM before finalizing the materials.

Flex boards offer widespread applications across industries, from consumer electronics to aerospace. Their flexibility, durability, and compact design make them indispensable in modern electronics.

By grasping the core concepts of Flex PCBs, from their construction to design strategies, you can harness this technology to its fullest potential.

Need help designing a flex circuit board? Post your questions and get them answered on our PCB forum, SierraConnect.

About Amit Bahl : Amit Bahl, widely recognized as the PCB Guy, earned his Bachelor of Science in Engineering from UCLA. He is currently the Chief Revenue Officer at Sierra Circuits, where he continues to lead efforts to simplify the PCB design journey and support designers and engineers in creating high-quality boards.