Related Categories — PCB Design

How to Reduce Ground Bounce in PCB Assembly

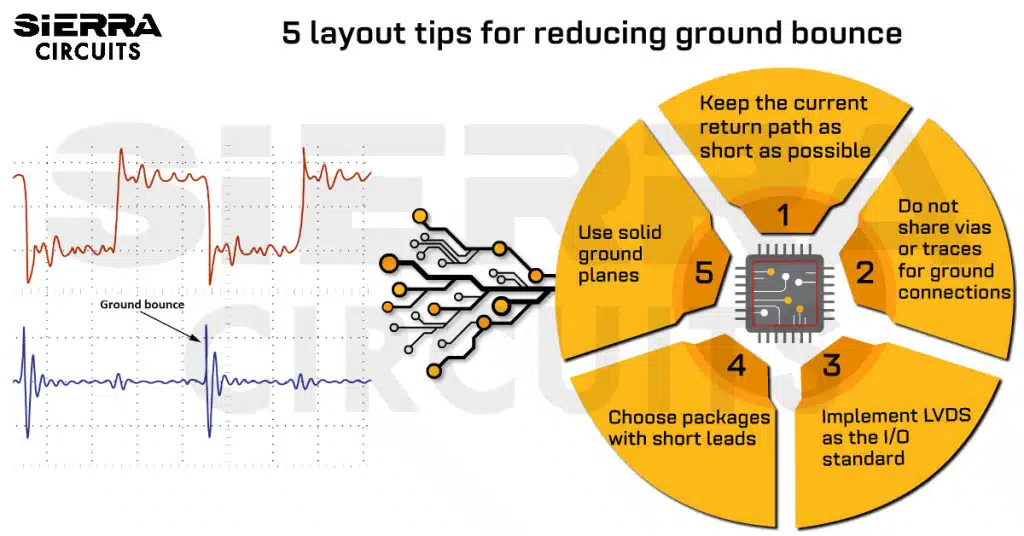

Ground bounce is a source of noise in a PCB assembly. It is important to prevent this as it interrupts high-speed or high-frequency operation. The major cause for ground bounce is the difference in ground potentials at various points on the circuit.

PCB Design

Best EMI and RF Shielding Methods for Flex PCBs

Flexible PCBs, like any other electrical interconnect, are susceptible to electromagnetic (EM) and radio frequency (RF) interference. The ... more »

EMI and EMC

How Vibrations in Space Vehicles Affect PCBA

Effects of vibrations on PCBA causes fatigue and eventually fail some parts in space missions. These electronic devices ... more »

Defense & Space

How to Reduce Ground Bounce in PCB Assembly

Ground bounce is a source of noise in a PCB assembly. It is important to prevent this as ... more »

PCB Design

Best EMI and RF Shielding Methods for Flex PCBs

Flexible PCBs, like any other electrical interconnect, are susceptible to electromagnetic (EM) and radio frequency (RF) interference. The ... more »

EMI and EMC

How Vibrations in Space Vehicles Affect PCBA

Effects of vibrations on PCBA causes fatigue and eventually fail some parts in space missions. These electronic devices ... more »

Defense & Space

Specifying Your Controlled Impedance Requirements

Circuit board manufacturers have invested in advanced modeling software and testing devices to specify the controlled impedance requirements ... more »

Controlled Impedance

Choosing Smaller Footprints for HDI Design

The main agenda of using HDI technology is to pack more components on a smaller board. Choosing smaller ... more »

HDI / Blind & Buried Vias

Top 6 Missing Information When Requesting a PCB Quote

Once a circuit board designer prepares the design, the next step is to find a manufacturer to transform ... more »

PCB Assembly

Impedance Matching in HDI PCB Design

Impedance matching is the way of configuring the input impedance of a load or the output impedance of ... more »

Controlled Impedance

Making Sense of Wave Soldering

Depending on component technology, many options exist for automated mass soldering today. But wave soldering was the first ... more »

PCB Assembly

What Should a PCB Fab Drawing Include?

A fab drawing is one of the different file types that convey the manufacturing details of a printed ... more »

PCB Design

Fabrication, Procurement, & Assembly. PCBs fully assembled in as fast as 5 days.

- Bundled together in an entirely-online process

- Reviewed and tested by Engineers

- DFA & DFM Checks on every order

- Shipped from Silicon Valley in as fast as 5 days

Fabrication. Procurement & Assembly optional. Flexible and transparent for advanced creators.

- Rigid PCBs, built to IPC-6012 Class 2 Specs

- 2 mil (0.002″) trace / space

- DFM Checks on every order

- 24-hour turn-times available

Complex technology, with a dedicated CAM Engineer. Stack-up assistance included.

- Complex PCB requirements

- Mil-Spec & Class 3 with HDI Features

- Blind & Buried Vias

- Flex & Rigid-Flex boards