Related Categories — IPC » PCB Design

How to Choose PCB Laminates Based on IPC Standards

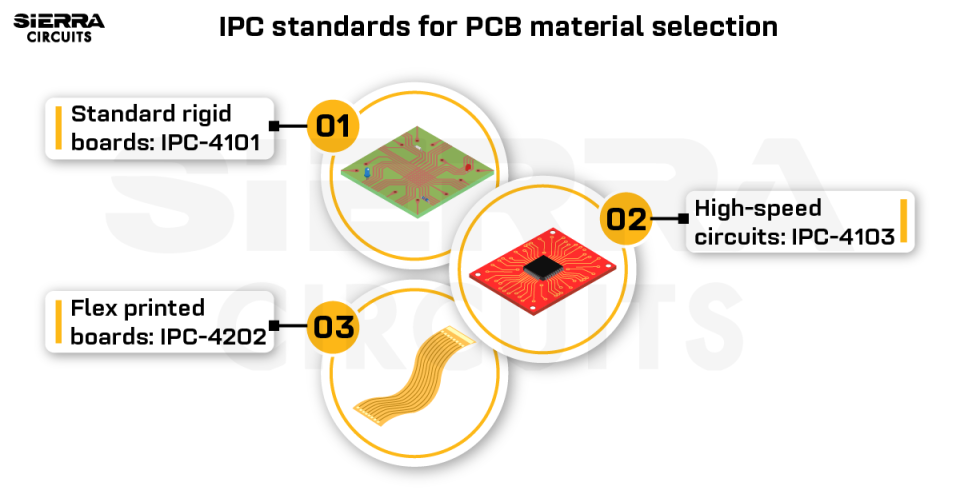

Following IPC standards for PCB laminates makes it easier to choose dielectric materials that fit the specific needs of rigid, […]

IPC

IPC Class 2 VS Class 3: The Different Design Rules

As circuit board manufacturers, designers often ask us about the difference between IPC Class 2 and Class 3. ... more »

IPC

IPC Standards and Guidelines for Testing Flex PCBs

What you should know about IPC guidelines for your flex PCB designs.

Flex PCBs

How to Choose PCB Laminates Based on IPC Standards

Following IPC standards for PCB laminates makes it easier to choose dielectric materials that fit the specific needs ... more »

IPC

IPC Class 2 VS Class 3: The Different Design Rules

As circuit board manufacturers, designers often ask us about the difference between IPC Class 2 and Class 3. ... more »

IPC

IPC Standards and Guidelines for Testing Flex PCBs

What you should know about IPC guidelines for your flex PCB designs.

Flex PCBs

How to Optimize Your PCB Trace Using IPC-2152 Standard

IPC-2152 is the standard for determining the current capacity, temperature rise, and width of a trace in a ... more »

IPC

Applying IPC-2221 Standards in Circuit Board Design

IPC-2221 is a generic standard for circuit board design. It lays down the requirements for PCB design and ... more »

IPC

IPC-6012 or IPC-A-600: Which Standard Should You Use?

The association connecting electronics industries – commonly known as IPC – is an international trade association serving the ... more »

IPC

IPC-2223 Standards and Design Violations for Rigid-Flex Boards

Rigid-flex circuit boards are the best solution for space-constrained environments. They can withstand a significant number of flex ... more »

Flex PCBs

IPC J-STD-001 Standard Soldering Requirements

J-STD-001 is a standard issued by IPC for soldered electrical and electronic assemblies. The standard specifies material specifications, ... more »

IPC

IPC-2581 Set to Retire Gerber Files Across the Board

Why IPC-2581 is the go-to standard in PCB manufacturing? Similar to the Mentor Graphics-owned ODB++ in terms of ... more »

IPC

Fabrication, Procurement, & Assembly. PCBs fully assembled in as fast as 5 days.

- Bundled together in an entirely-online process

- Reviewed and tested by Engineers

- DFA & DFM Checks on every order

- Shipped from Silicon Valley in as fast as 5 days

Fabrication. Procurement & Assembly optional. Flexible and transparent for advanced creators.

- Rigid PCBs, built to IPC-6012 Class 2 Specs

- 2 mil (0.002″) trace / space

- DFM Checks on every order

- 24-hour turn-times available

Complex technology, with a dedicated CAM Engineer. Stack-up assistance included.

- Complex PCB requirements

- Mil-Spec & Class 3 with HDI Features

- Blind & Buried Vias

- Flex & Rigid-Flex boards