PCB Design Guides

Gain the know-how required to design your next manufacturable, functional, and reliable PCB.

Design your boards correctly from the start. Sierra Circuits’ PCB design guides provide critical information to prevent delays and avoid unnecessary costs.

FILTER:

KiCad 9 Step-by-Step Guide

6 chapters - 41 pages - 30 minute read

KiCad 9 Step-by-Step Guide walks you through the complete PCB design workflow using the latest version. The tutorial gives you a strong head start in understanding the fundamentals of this EDA tool.

What's Inside

- A complete KiCad 9 workflow from project creation to production file generation

- Step-by-step guidance on creating custom libraries and linking symbols to footprints

- Practical design checks: ERC and DRC

- Best practices for generating a clean BOM and fabrication-ready Gerber files

PCB Stack-Up Design Guide

12 chapters - 55 pages - 60 minute read

The stack-up design significantly impacts PCB factors such as signal integrity, power distribution, and thermal management. It provides the mechanical support necessary to withstand physical stresses and environmental factors.

What's Inside

- Design guidelines for HDI, flex, and hybrid stack-ups

- Stack-up representation in fab drawing

- DFM checks for layer stacks

- Characteristics of high-speed materials

- Manufacturing tolerances

- PCB stack-up examples with illustrations

Design for Testing Handbook

7 chapters - 28 pages - 45 minute read

Sierra Circuits’ Design for Testing Handbook will help you understand the importance of PCB testing, various inspection methods, and which one to choose to procure a flawless board. Design optimization and manufacturing entail substantial efforts and time.

What's Inside

- PCB testing strategies

- Guidelines to design and place a test point for FPT

- Directives to make your board ICT compatible

- Benefits and drawbacks of various testing methods

- Defects that you can identify through board testing

Already have your project designed?

Learn how we can deliver your High-Density Interconnect PCBs at scale.

Soldering Flux eBook

13 chapters - 24 pages - 40 minute read

Jim Smith says, “Perfect soldering is easy provided we make it easy.” The hard part is learning what makes soldering easy. And perhaps nothing is more important than understanding flux selection and proper usage, which you will after reading this Soldering Flux eBook.

What's Inside

- Why flux is needed

- The ingredients of flux and what they do

- Soldering flux categories

- How to read a flux manufacturer’s technical data

- The best flux for various applications

High-Speed Material Design Guide

6 chapters - 19 pages - 30 minute read

The material used in your stack-up has a significant impact on multiple aspects of PCB functionalities such as signal integrity, and thermal and mechanical stability. Thus, choosing the right substrate will help you evade crises during the production process.

What's Inside

- Importance of choosing the right material for your high-speed design

- Parameters that affect material selection

- Effect of dielectric constituents on your circuit board

- Characteristics of high-speed materials

- Effect of resin content and glass weave structure on your PCB

Connector Design Guide

5 chapters - 32 pages - 50 minute read

This design guide will help you overcome the challenges of incorporating PCB connectors in a system.

What's Inside

- Basics

- Terminology

- Selection and layout rules

- Testing

- Application-specific PCB connectors

Reduce Re-Spins with our Zero Defect Guarantee.

Our platform sources the whole package, creating a thread from design to delivery. Fabricating PCBs. Procuring parts. Assembling your boards.

Once you upload your BOM, Our best-in-class software automatically checks for errors and cleans your file for you. After you place an order, your dedicated CAM engineer will run a full DFM and DFA check to ensure your prototype achieves Zero Defect every time—all at no additional cost to you.

Get to market faster and spend less time troubleshooting.

RF & Microwave Design Guide

8 chapters - 44 pages - 60 minute read

This design guide will take you through each and every step to create a high-frequency communication board layout.

What's Inside

- Basics of RF and microwave board design

- Choosing RF materials

- Trace, grounding, via, and stack-up design

- Component selection and placement

- Testing and isolation requirements to avoid interference

PCB Material Design Guide

9 chapters - 30 pages - 40 minute read

PCB material selection is the first step in the design process. The type of materials you choose defines the quality of your end product.

What's Inside

- Basic properties of the dielectric material to be considered

- Signal loss in PCB substrates

- Copper foil selection

- Key considerations for choosing PCB materials

IPC Class 3 Design Guide

8 chapters - 23 pages - 35 minute read

The Sierra Circuits IPC Class 3 Design Guide helps you design high-reliability PCBs for electronics that won’t fail.

What's Inside

- IPC guidelines for manufacturing defects

- IPC standards for assembly processes

- Common differences between the classes

- IPC documents to set the level of acceptance criteria

High-Speed PCB Design Guide

8 chapters - 115 pages - 150 minute read

The Sierra Circuits High-Speed Design Guide helps you design PCBs with signal frequencies from 50MHz to as high as 3GHz and beyond.

What's Inside

- Explanations of signal integrity issues

- Understanding transmission lines and controlled impedance

- Selection process of high-speed PCB materials

- High-speed layout guidelines

Controlled Impedance Design Guide

6 chapters - 56 pages - 60 minute read

This Controlled Impedance Design Guide empowers PCB designers with the knowledge required to develop high-speed boards.

What's Inside

- Understanding why controlled impedance is necessary

- Stack-up design guidelines

- How to design for impedance

- Common mistakes to avoid

HDI PCB Design Guide

5 chapters - 52 pages - 60 minute read

The Sierra Circuits HDI Design Guide provides the guidelines for blind and buried via technology.

What's Inside

- Planning your stack-up and microvia structure

- Choosing the right materials

- Signal integrity and controlled impedance in HDI

- Manufacturing considerations for higher yields

Flex PCB Design Guide

10 chapters - 39 pages - 45 minute read

The Sierra Circuits Flex PCB Design Guide helps you design highly flexible PCBs for electronics that move with you.

What's Inside

- Calculating the bend radius

- Annular ring and via specifications

- Build your flex stack-up

- Controlled impedance for flex

- The fab and drawing requirements

PCB Transmission Line eBook

5 chapters - 20 pages - 25 minute read

The Sierra Circuits PCB Transmission Line eBook helps you design zero-defect PCBs for electronics that move with you.

What's Inside

- What is a PCB transmission line

- Signal speed and propagation delay

- Critical length, controlled impedance and rise/fall time

- Analyzing a PCB transmission line

Differential Pair eBook

3 chapters - 18 pages - 30 minute read

The Sierra Circuits Differential Pairs eBook provides a detailed explanation for understanding differential pairs in transmission lines for reliable PCB design.

What's Inside

- Differential and common mode signals

- Differential impedance

- Even and common modes

- The physical parameters

Design for Manufacturing Handbook

10 chapters - 40 pages - 45 minute read

Make sure your design will be manufacturable the first time. Our DFM Handbook provides guidance PCB designers, engineers and manufacturers need to ensure the manufacturability of the designs.

What's Inside

- Annular rings: avoid drill breakouts

- Vias: optimize your design

- Trace width and space: follow the best practices

- Solder mask and silkscreen: get the must-knows

Signal Integrity eBook

6 chapters - 53 pages - 60 minute read

The Sierra Circuits Signal Integrity eBook provides insights for designing highly complex PCBs for electronics.

What's Inside

- Impedance discontinuities

- Crosstalk

- Reflections, ringing, overshoot and undershoot

- Via stubs

Design for Assembly Handbook

6 chapters - 50 pages - 70 minute read

Our DFA Handbook outlines a reliable system to help you reduce cost and speed up the production of your prototype PCBs.

What's Inside

- Recommended layout for components

- Common PCB assembly defects

- Factors that impact the cost of the PCB assembly, including:

- Component packages

- Board assembly volumes

KiCad Design Guide

10 chapters - 161 pages - 180 minute read

Get the best out of your board with KiCad, one of the best open-source electronic design automation tools for PCB design!

What's Inside

- Creating a component symbol library

- Setting up board parameters and rules

- How to route differential pairs

- How to place of components

Never miss our PCB design tips.

Subscribe today to our newsletter and receive our best blogs that will help you design for success.

Your information is secure. Please read our privacy policy for more information

Fabrication, Procurement, & Assembly. PCBs fully assembled in as fast as 5 days.

- Bundled together in an entirely-online process

- Reviewed and tested by Engineers

- DFA & DFM Checks on every order

- Shipped from Silicon Valley in as fast as 5 days

Fabrication. Procurement & Assembly optional. Flexible and transparent for advanced creators.

- Rigid PCBs, built to IPC-6012 Class 2 Specs

- 2 mil (0.002″) trace / space

- DFM Checks on every order

- 24-hour turn-times available

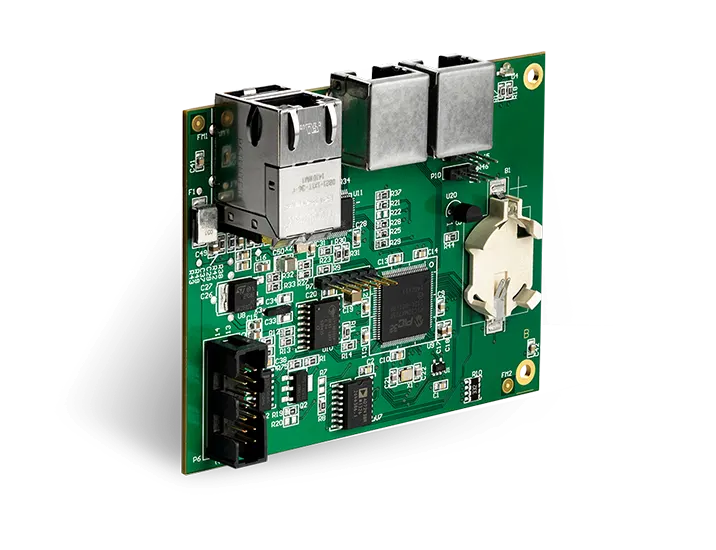

Complex technology, with a dedicated CAM Engineer. Stack-up assistance included.

- Complex PCB requirements

- Mil-Spec & Class 3 with HDI Features

- Blind & Buried Vias

- Flex & Rigid-Flex boards