Contents

On-demand webinar

How Good is My Shield? An Introduction to Transfer Impedance and Shielding Effectiveness

by Karen Burnham

Punch Through Design is a Bluetooth expert, providing hardware and software design services for clients that are developing cutting-edge wireless accessories for the iPhone, iPod, and iPad.

Punch Through Design sends prototype circuit board designs to Sierra Circuits, who is then able to turn around the boards in 24 hours, keeping the development process moving forward.

Quickturn PCB Case Study: Punch Through Design

Business Issue:

Punch Through Design needed a way to speed up design, development, and testing processes, but building prototype circuit boards proved to be time-consuming.

Results:

The design firm now outsources PCB manufacturing and assembly to Sierra Circuits, who can turn them around in 24 hours. The streamlined prototype development process allows Punch Through Design to meet its clients’ aggressive development deadlines so they can go to market quicker.

“It really is amazing. We send the designs out, and the circuit boards are delivered to our office the next day—100 percent accurate. This allows us to continue working toward a final design without having to wait on manufacturing or testing.”

– Colin Karpfinger, co-founder, Punch Through Design

The Story Behind the Boards

Like mobile app development, accessory manufacturing is a cut-throat industry. Whether they are building temperature sensors, speakers or headsets, being first to market gives manufacturers a huge advantage, providing enough time to build a brand and marketshare before imitators hit the market. As a result, PCB design, testing, and manufacturing of the products’ circuit boards need to be completed quickly and efficiently.

That’s where Punch Through Design comes in. Manufacturers approach the design firm to develop custom circuit boards that fit the accessories’ specific applications and product design. However, according to Colin Karpfinger, the company’s founder, building Alpha and Beta versions of a circuit board, testing the designs, and moving to the pre-production phase can take months—time that Punch Through Design’s customers do not have.

“Time is certainly of the essence,” Karpfinger said. “Our clients are working toward investor pitches or grant deadlines and don’t have time to wait for prototype circuit boards to be manufactured. We needed a way to speed time to market for our customers.”

High-Speed PCB Design Guide

8 Chapters - 115 Pages - 150 Minute ReadWhat's Inside:

- Explanations of signal integrity issues

- Understanding transmission lines and controlled impedance

- Selection process of high-speed PCB materials

- High-speed layout guidelines

Download Now

Outsourced PCB Assembly

Punch Through Design engineers used to assemble the prototype circuit boards in-house, but the process would take up to a week to get the required number of viable boards ready for testing, and that was valuable time better spent on design. Karpfinger had previously worked with a company called Sierra Circuits in Sunnyvale, Calif. that specialized in quick turnaround PCB manufacturing and surface mount assembly, and he decided to give them a call to see if they could speed up the company’s design processes.

Now, with Sierra Circuits’ partnership, Punch Through Design is able to send out designs and have circuit boards assembled and delivered virtually overnight, dramatically shortening development and manufacturing processes. Now, the circuit boards are built to exact specifications, and with quality control and accuracy that was difficult to maintain when assembled in-house. Outsourcing the PCB manufacturing and PCB assembly

to Sierra Circuits allows the company’s engineers to focus on other aspects of product design rather than building hardware—improving overall quality while speeding delivery.

“It really is amazing,” Karpfinger said. “We send the designs out, and the circuit boards are delivered to our office the next day—100 percent accurate. This allows us to continue working toward a final design without having to wait on manufacturing or testing.”

Meeting Deadlines Speeds Time to Market

Sierra Circuits allows Punch Through Design to quickly and easily meet aggressive design and manufacturing deadlines from its clients. Prototype circuit boards can be designed, manufactured to scale, put into prototype products, tested again, tweaked, and rebuilt—all within a few weeks. While it used to take Punch Through Design a week to assemble ten viable circuit boards, Sierra can deliver them virtually overnight and guarantee they are all built to exact specifications.

This turnaround capability has allowed the firm to bid more aggressively on quick-turnaround projects, giving it the confidence that the aggressive deadlines can be met. The consistency and accuracy of Sierra Circuit’s boards also give the firm a better idea of how long a specific project would take, allowing them to give clients more accurate timelines during the RFP process, and it can be more aggressive on timelines when bidding for work. Overall, Sierra Circuits gives Punch Through Design a decisive differentiator over competing firms.

To turn your PCB concept into reality, read building a PCB prototype from scratch: A designer’s guide.

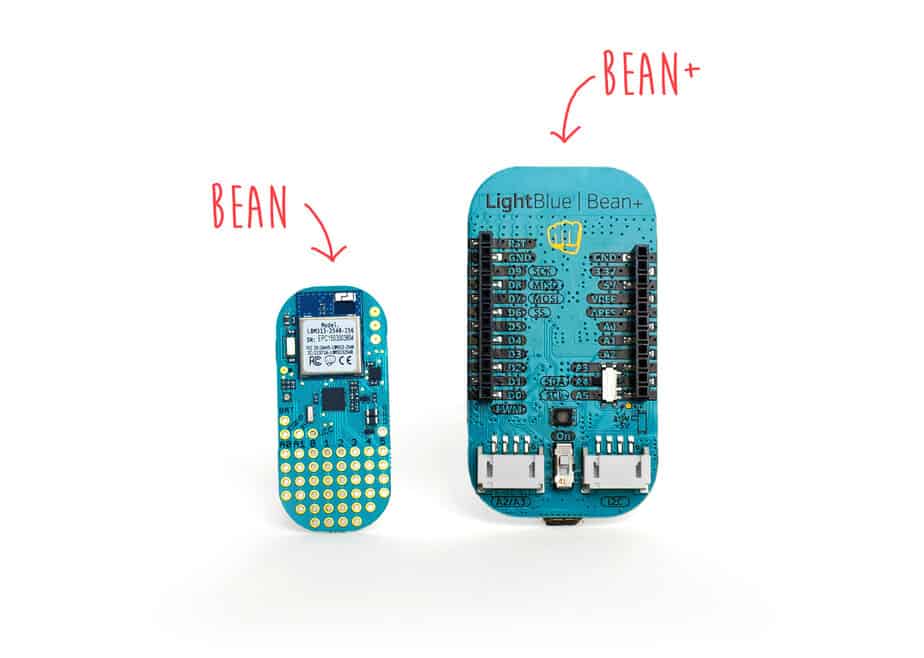

The Bean Goes Blue

In addition to consulting clients on their Bluetooth accessories, Punch Through Design offers its own product, LightBlue Bean—an Arduino microcontroller that allows developers to program wirelessly using Bluetooth. The new LightBlue Bean+ recently raised more than $165,000 on Kickstarter—552 percent of its fundraising goal. Because the product is essentially a naked circuit board that would most likely not be packaged behind a casing, Punch Through Design needed a way to differentiate the Bean and allow it to stand out. Karpfinger remembers calling several industry-scale circuit board manufacturers to see if they could add a blue dye to the solder mask.

Due to the uniqueness of the request, manufacturers were reluctant to add the step to their manufacturing process. It was just something they didn’t want to do. He finally asked his contact at Sierra Circuits to see if they could do it. Within days, Karpfinger had a prototype with the blue color that has since become synonymous with Bean. Sierra Circuits now manufactures the circuit boards at scale even though it has traditionally been focused on the low-scale prototype market.

“We had a ridiculous ask that Sierra Circuits didn’t even blink at, and now I can’t imagine the Bean any other way,” Karpfinger said. “No matter how unique, they will find a way to meet your needs.”

Quote and order your circuit boards online with our Turnkey PRO tools in just a few minutes.