Contents

On-demand webinar

How Good is My Shield? An Introduction to Transfer Impedance and Shielding Effectiveness

by Karen Burnham

What is the first thing that comes to your mind when someone says revolution? Change, rather a change for good. Something that alters the way of things to be. In most cases, the change that manifested was necessary. Industry, the sector of the economy concerned with the manufacturing of goods, has also undergone several revolutions. The one in which we are putting our money in is the 4th industrial revolution or what we refer to as Industry 4.0.

The first industrial revolution saw mechanization through water and steam power. Then came mass production and assembly line using electricity in the second. The fourth industrial revolution will move forward with what started in the third with the adoption of computers and automation. And further, enhance it with smart and autonomous systems fuelled by data and machine learning.

So, what is this Industry 4.0?

We have already been reading a lot about this envisaged technology framework that will enable Industry 4.0. This will completely rearrange the legacy of production processes. The revolution will see the transition from analog, centralized workflows to digital, decentralized production processes. The ultimate goal of all this digitization is to create self-steering or autonomous production processes. Customer orders will apparently be able to drive themselves throughout the supply chain and manufacturing processes with little to no human intervention. This new framework will enable breakthrough gains in production efficiency, boost overall yield, and lower production costs substantially.

But this revolution is still in its infancy; therefore, it is not really plausible to define all of its attributes. To measure how revolutionizing, it is or to what extent it will transform an industry or the economic landscape, is still foggy. Even though some dismiss Industry 4.0 as merely a marketing buzzword, shifts are happening in manufacturing that deserves our attention.

What are the major attributes of Industry 4.0?

- Industrial IoT- Well, it is as the name suggest Internet of Industrial Things. Or in layman’s term, it is an IoT structure within an industrial facility where machines communicate and exchange data with each other and other system devices.

- Automated Robotics- The machines interacting with each other will upgrade the aspect of them working autonomously in a given ecosystem.

- Cloud- The cloud will serve the same purpose as it does in IoT, it will store and transfer or share data whenever one wants, wherever one wants.

- Big Data Processing- It will become mandatory to have all the data in open source, so that big chunks of data can be accessed anytime, anywhere.

- Additive Manufacturing- Market of customized devices and components are gaining momentum; investors to customers, people are all game about this idea.

- Augmented Reality (AR) and Virtual Reality (VR)- Another interesting technology gaining momentum is VR and AR. They have the ability to simulate processes before actual physical runs. Therefore, reducing downtime for changeovers.

These are some of the few very significant attributes, the list is not exhaustive!

PCB and Industry 4.0

Widely regarded as the fundamental building blocks of electronic devices, PCB production provides a good window into the technological evolution; Industry 4.0. It will be interesting to see how much of a role are PCB really going to play in those fancy marketing words like Smart Homes, Smart Cars, and Smart Cities?

Actually, a lot, PCB designers probably have the hardest job of all when it comes to IoT. On one hand, there is the technology that keeps on advancing and then, there is cramming in all of that advanced functionality into package sizes that keep on shrinking. Let us show you some (not all!) of the challenges you need to put up against.

First of all, get ready to fight for every micron space of your layout. The days of having extra layout spaces were long gone. But now, with IoT devices on the floor, it’s not even the least required space.

Also, forget about the time when you would design just the PCB and hand it over to your mechanical friend for a fit check. In the world of IoT, this workflow doesn’t work anymore. With smaller form factors, you will be designing the entire product rather than just a PCB.

How?

Well, by becoming the best mate of your mechanical engineer. Because both you and your engineering team need to work in sync. In real time at every stage of the design journey, modifications to both a mechanical assembly and circuit board have to be shared between disciplines. Just remember you are no longer just designing circuit boards; you’re developing products for the connected world.

While you ponder about the offsets, we ensure that Industry 4.0 is not only about challenges. Let’s take a detour and figure out what good it does.

PCB manufacturers are often found struggling to make sense out of the huge data flooding in from a multitude of sources. It is particularly tough when there is a wide variance among the data attributes to be analyzed. With big data in the market, PCB manufacturers can more quickly extract the valuable data they need to make more informed decisions. Digital processes such as direct imaging, inspection, laser drilling, and legend digital printing are accurately measuring and inspecting the PCB panels in different production stages.

Also, real-time, high-precision inspection shortens decision-making cycles and improves yield. Again tracking every step of manufacturing and PCB assembly can efficiently reduce product recalls. Since recalls are expensive with a complete record of the production process, defective PCBs can be identified and isolated early—long before they’re built into the end device.

Industry 4.0 is definitely a revolutionary approach to manufacturing techniques.

The concept will push global manufacturers to a new level of optimization and productivity. Not only that, but customers will also enjoy a new level of personally customized products unlike ever before.

However, there will be many challenges waiting to be tackled systematically to ensure a smooth transition. Not only hard work but smart work will materialize Industry 4.0.

While speculations regarding privacy, security, etc. need more study, the overall picture is promising. Such an approach to manufacturing industries is truly revolutionary.

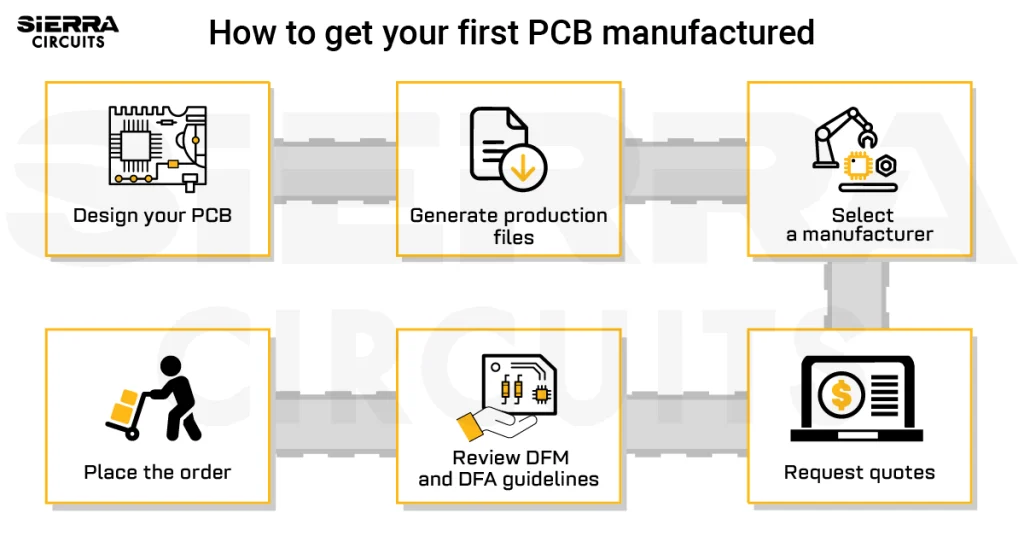

Quote and order your circuit boards online with our Turnkey PRO tools in just a few minutes.