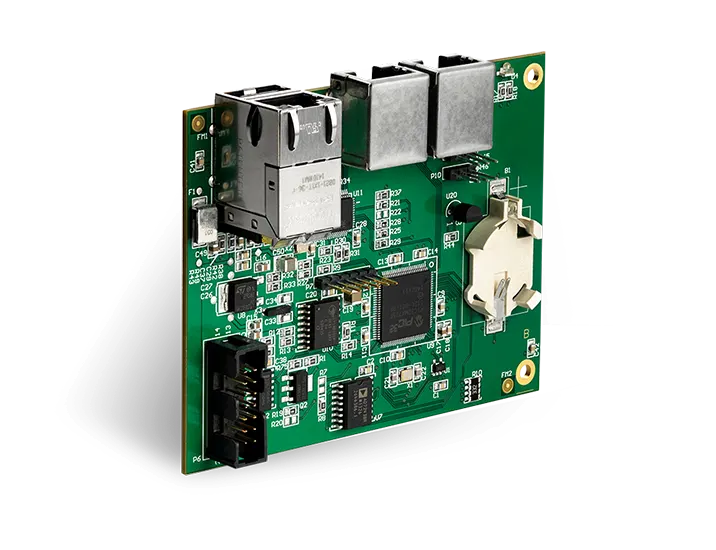

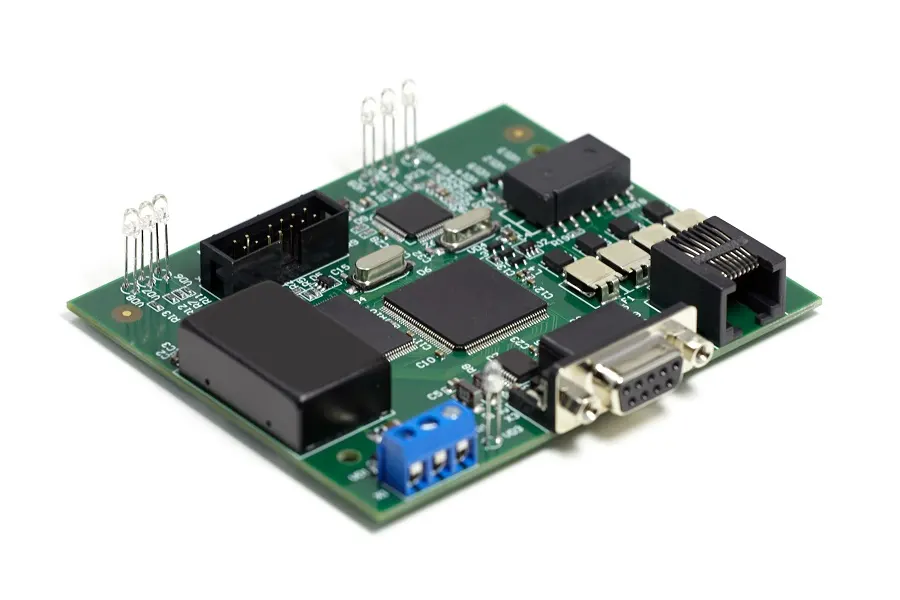

Sierra Standard Product for your PCB manufacturing and assembly

The Sierra Standard Product is our new online quoting and ordering platform for PCB manufacturing and assembly. Quote and order your assembled circuit board within 5 minutes. Receive your products within 10 or 15 days. Our circuit boards are proudly fabricated and assembled in Silicon Valley.

The Sierra Standard Product offers real-time stock visibility and seamless integration with suppliers to ensure transparent pricing. You can receive an online quote for PCB manufacturing, components, and assembly, all made in America, in less than 5 minutes.

- PCB fabrication

All PCBs are made with US materials and are built to IPC-A-6012 Class 2 in our Silicon Valley facilities. - Component procurement

Components are procured from authorized distributors, checked for counterfeit, and electrically tested. - Assembly

0201 component placement through our Pick-and-Place machines with AOI and X-ray.

At Sierra Circuits, our engineers and turnkey PCB build teams are always accessible and responsive throughout the entire process, from the initial quote to production and shipping. We take pride in offering top-notch American-made PCB solutions.

Product Promise

Get your PCBs fast without sacrificing quality.

Our services are all in-house:

- PCB fabrication

- Component procurement

- Assembly

- DFM check

Assembly specs:

- BOM availability check

- DFA check

- 100% net-list testing

Get USA-quality prototypes

- 5 or 10 fully assembled boards

- Delivered within 10 days

- Built to IPC-6012 class 2 specs

- UL approved

Sierra Standard Product Fabrication & Assembly Capabilities |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Board Type | Only rigid boards. Standard Product service provides both fabrication and full assembly of your boards (including component procurement). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Board Shape | We expect boards to be generally rectangular in shape. Notches, cutouts and slots are allowed (some restrictions shown below). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Board Spec | Boards will be built to IPC-6012 Class 2 Spec. However, in this online offer, we do not provide any microsection certificates or IPC coupons to customers. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Fabrication of ITAR / EAR Controlled Designated Jobs? | No | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| RoHS Available? | Yes, your board can be RoHS if you choose RoHS-compliant surface finish (ENIG). You have an option to not have any RoHS markings on your board if you so choose. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Layers Allowed | 2 layers, 4 layers, 6 layers, and 8 layers. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Laminations | Single lamination double-sided or multi-layer boards only. In this online offer, we do not provide boards that need multiple laminations or have HDI features. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Blind Vias | No | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Buried Vias | No | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Tented Vias | No | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| High-Density Interconnect (HDI) | No. In this online offer we only provide single lamination PCBs with through-hole vias. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Non-Plated Holes | Yes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Data for PCBs | For PCBs: We prefer RS-274X extended Gerber format or ODB++. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Data for Assembly | For assembly: You will need to upload your BOM (excel format) online for quoting. In the final package, we will need the assembly drawing and XY data.We prefer ODB++ data for your orders that require assembly. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Turntimes | 5 days for PCB fabrication, or 10 days for fully assembled boards. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Cut-Off Time | 5:00 PM. Day 0 begins when validation is done or the final consigned components are received, whichever is later. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Order Quantities | For most designs, quantity 5 & 10 assembled PCBs available. Some limitations apply based on the number of panels to be produced and the turntime expected. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Maximum Board Size | Must fit a 15" x 9" box. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Minimum PCB Dimensions | 1" x 1" | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Material | FR4, FR4-lead free. Standard materials are instantly quoted online. Exotic materials may be quoted by a specialist offline. Please note that this service is for rigid PCBs only. For flex or rigid-flex PCBs, please get a custom quote directly through a Sierra sales person. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Thickness & Thickness Tolerance | 0.062" with thickness tolerance of +/- 10%. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Arrays | Arrayed designs are not allowed. Your PCB design must have just a single image of a single board. (Our engineers will array it as needed for Sierra assembly and finally ship you fully-assembled individual boards.) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Minimum Trace / Space | 4 mils | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Standard Copper Overplate | Surface pattern: Nominal 1 oz/sq foot. (0.0013" to 0.002") (33 microns to 51 microns) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Outer Layers Copper (Finished) | 1 oz. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Inner Layers Copper | You can choose between 0.5 or 1 oz. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Maximum Number of Holes Per Board | 80 holes / square inch | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Minimum Annular Ring Width | 0.006" | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Controlled Dielectric | In this online service, you cannot specify controlled dielectric, but we offer +/-10% controlled impedance (see below). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Controlled Impedance ? | In this “standard product” we only offer impedances of 50 Ohm Single Ended, 90 Ohm Differential, and 100 Ohm Differential. To get these impedances, the trace width/spacing on your design on specific layers must adhere to our impedance table provided. For each of the 2 layer, 4 layer, 6 layer, and 8 layer product we have provided impedance tables that you must refer to and match your design to the trace widths required and we will manufacture your board to meet those specific impedance requirements. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Multiple Parts in one design | To keep our online service low-priced and hassle-free, we keep it simple. We do not allow different PCB designs and multiple BOMs to be combined in one order. Our system can only accept design files for a single circuit board with a single BOM. We cannot merge BOMs, de-duplicate multiple BOMs, etc. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Solder mask | Solder masks are available in green. They can be used on both sides. However, in this service, we only offer LPI solder masks. Note: Sierra only offer LPI solder mask in this service. If your design forces us to use laser direct imaging LPI (LDI-LPI) solder mask, we will contact you and get approval for a $500 extra charge on your order. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Legend / Silkscreen | White. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Notches, Cutouts and Slots | Up to 10 plated slots allowed per board. Up to 10 non-plated slots allowed per board. Up to 10 cutouts allowed per board. Up to 10 notches allowed per board. (If any of the above allowances are exceeded in your design, we can still process it for a minimum $100 extra lot charge on your order. We will get your approval before doing so.) Minimum inside radius (for any notch, cutout or slot) = 20 mil (0.02"). Minimum width (of any notch, cutout or slot) = 40 mil (0.04"). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Logo | Vendor markings include Company Logo, UL marking, Flammability, etc. Such vendor markings will be put in Bottom Silkscreen. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| IPC coupons & Microsection reports | Not provided in this online offering. Only available in custom ordered products. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Electrical Testing | Electrical testing is mandatory for all boards. This is the only way for any PCB manufacturer to ensure the product shipped has zero shorts or opens.

Visual inspection can never be 100% effective. Especially, if the defect is under the solder mask, electrical test is the only way to catch it. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Shipping Options | FedEx / UPS, Will Call. You can use your own FedEx / UPS account number. International shipments allowed. All duties / customs are the responsibility of the customer. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Payment Terms | Credit card (PO allowed for select customers who have set up credit terms). Payment link convenience: If your purchasing department typically puts in credit card number, you can still place an order and our system will email a payment link to that person. Order will start when payment information is received. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Assembly Class Specs | IPC-A-610-Class2 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Assembly of ITAR Designated Jobs? | No. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Assembly on Both Sides | Yes. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Minimum Passive Component Size | 0201 (inches) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Maximum Number of Through-Hole Components | 20 per board | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Minimum Component Pad Size | Minimum 8 mils x 8 mils or 8-mil diameter | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Assembly Restrictions | These features are not allowed: Wire-bonding, conformal coating, underfills, staking, POP assembly, wire/cable assembly. Rework like cutting traces, wire jumpers. Assembly of PEM nuts, turrets terminals, rivets, and press-fit connectors. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Other Restrictions | No First Article Reports will be provided No X-Ray images will be provided No Flying Probe Test will be provided |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Trusted by innovators

Engineers and PCB designers at the world's most innovative companies choose Sierra Circuits for top quality PCBs.

Standard high-quality and fully assembled PCBs made in Silicon Valley.

For designers and engineers facing tight deadlines or seeking supply chain simplification, the Sierra Standard Product stands out as the most reliable full-service turnkey PCB solution available.

Ideal for:

- PCB designers and electrical engineers building prototypes or bringing products to market.

- Contract manufacturers who need fast, predictable lead times.

- Purchasing teams who require pricing and supply-chain transparency.

- Tinkerers, hobbyists, and builders who would benefit from the expertise of our in-house CAM engineers.

The Sierra Standard Product also includes:

- PCB fabrication

- Component procurement

- In-house assembly

- DFM check

Manufacturing Equipment at Sierra Circuits

Our 70,000 sqft state-of-the-art campus in the heart of Silicon Valley contains the most advanced equipment required for the manufacture and assembly of your PCBs. Whether you’re looking for standard quick turn PCBs or boards with the tightest tolerances, made from exotic metals, there’s a reason Sierra Circuits leads the industry in quality and performance.

Fabrication, Procurement, & Assembly. PCBs fully assembled in as fast as 5 days.

- Bundled together in an entirely-online process

- Reviewed and tested by Engineers

- DFA & DFM Checks on every order

- Shipped from Silicon Valley in as fast as 5 days

Fabrication. Procurement & Assembly optional. Flexible and transparent for advanced creators.

- Rigid PCBs, built to IPC-6012 Class 2 Specs

- 2 mil (0.002″) trace / space

- DFM Checks on every order

- 24-hour turn-times available

Complex technology, with a dedicated CAM Engineer. Stack-up assistance included.

- Complex PCB requirements

- Mil-Spec & Class 3 with HDI Features

- Blind & Buried Vias

- Flex & Rigid-Flex boards