PCB assembly in the United States

Sierra Circuits stands as your premier destination for PCB assembly services in Silicon Valley, providing an all-encompassing solution that caters to your project’s scale and complexity. Whether you’re in the early stages of prototyping or preparing for mid-scale production, our services are designed to meet your diverse needs seamlessly.

- SMT assembly

- BGA assembly

- Through-hole assembly

- Mixed assembly

- Rigid-flex printed circuit board assembly

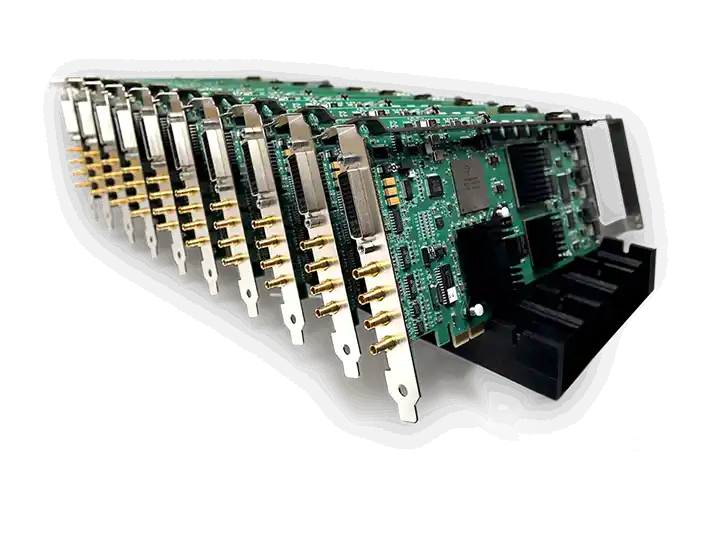

From through-hole and SMT to BGA and rigid-flex assembly

Our surface mount technology (SMT) assembly service boasts precision and efficiency, ensuring the accurate placement of components ranging from standard resistors to sophisticated integrated circuits. We excel in ball grid array (BGA) assembly, showcasing our proficiency in handling complex components with finesse, ultimately contributing to optimal performance.

Through-hole assembly is seamlessly integrated into our comprehensive suite of services, accommodating a variety of component types and ensuring robust connections. Our expertise extends to mixed assembly, where we adeptly combine SMT and through-hole technologies to meet the unique requirements of your design.

In addition to these capabilities, we specialize in rigid-flex printed circuit board assembly, providing a flexible and durable solution for applications demanding intricate and dynamic designs.

Our commitment to quality and precision is unwavering, making us your trusted partner for reliable and scalable PCB assembly services. Experience the convenience of a one-stop solution tailored to your project’s specifications, backed by our dedication to excellence in manufacturing.

Sierra Circuits supports IPC-2581.

Unlock the full potential of your PCB assembly with the industry-recognized IPC-2581 standard. IPC-2581 is a pivotal standard for the exchange of data in circuit board manufacturing. This open, vendor-neutral XML format streamlines communication, ensuring clarity and precision in design data transfer. From layer stack-up to drill details, IPC-2581 simplifies the entire process, fostering collaboration and reducing the likelihood of errors during data transfer. By adhering to this standard, Sierra Circuits enhances the efficiency and accuracy of PCB production, offering a seamless integration from design to assembly. Join us in embracing IPC-2581 for a future-ready and streamlined manufacturing experience.

Product Promise

We source components from chip manufacturers across the globe, including Mouser, Digi-Key, Arrow Electronics and others. We also warehouse a significant inventory of common parts. If we cannot source a specific component, our engineers will make recommendations for fair-price alternatives.

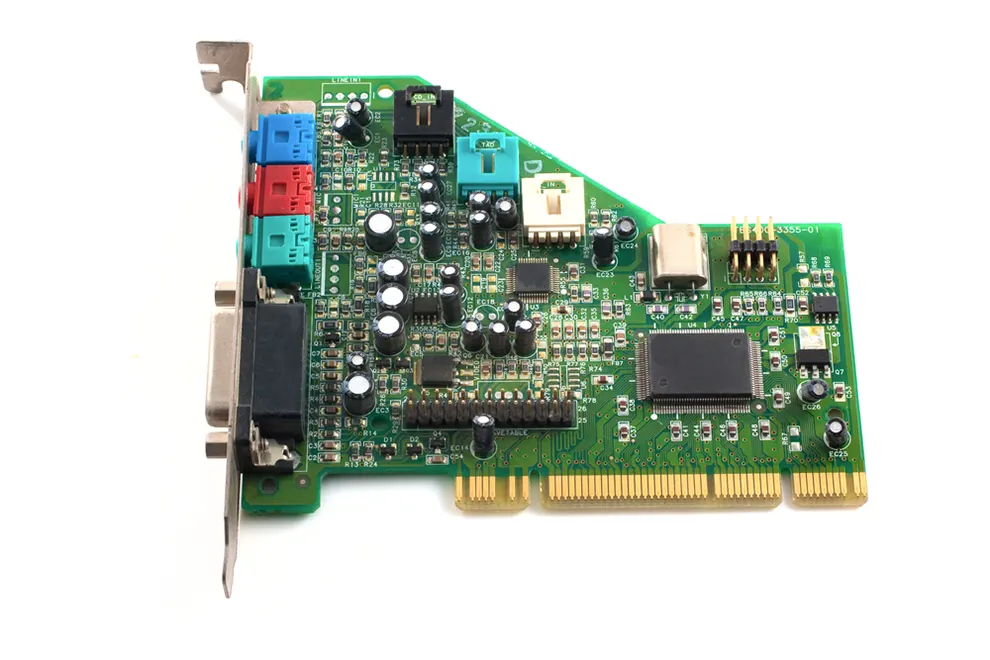

General assembly capabilities

- BGA, micro-BGA, QFN, CSP and any leadless devices up to .35mm pitch assembly with 100% 3D X-ray inspection

- PCB components, including all types of BGAs, QFNs, CSPs, 0201, 01005, 08004, POP, and press fit components in small quantities

- DFA process identifies almost all manufacturing issues before actual assembly saving production holdups

- RoHS, leaded, indium, clean & no clean chemistries

- Paste in-hole

- De-ionized water cleaning of assembled boards

Full turnkey PCBs

Sierra Circuits creates an unbroken thread from design to delivery. Receive a complete quote for fabrication, assembly, and components—entirely online. Our white-glove service brings your product to life.

Partially consigned assembly

Some parts provided by the designer — we will source the rest. Sierra Circuits will work with your supply chain to get your PCBs assembled and to market quickly.

Consigned assembly

All components are provided by the PCB designer. Sierra Circuits will fully assemble your PCBs and ship them to you. Quick turn times available, with fully transparent pricing.

One-stop PCB assembly services, capabilities, and testing

We source components from chip manufacturers across the globe, including Mouser, Digi-Key, Arrow Electronics and others. We also warehouse a significant inventory of common parts. If we cannot source a specific component, our engineers will make recommendations for fair-price alternatives.

Assembly services

- NPI: New product introduction

- SMT: Surface mount assembly, single & double-sided

- Plated through-hole: Selective soldering

- Mixed technologies: SMT, through-hole, electro-mechanical assembly

PCBA testing

- Flying probe test including boundary scan

- Functional test: Board & system level test including engineering support for developing test platforms

Engineering services

- DFM, DFT, DOE

- Develop control plans & pFMEA

- Value add engineering services

Other value-add services

With our strategic partners, Sierra Circuits expertise extends to the following:

- Reliability test includes temperature cycling

- Wire bonding

- Conformal coat

- ICT: Develop test fixtures and testing with our key partners

Trusted by innovators

Engineers and PCB designers at the world’s most innovative companies choose Sierra Circuits for the highest quality one-stop PCB assembly services, right here in the USA.

Upload your BOM for an Online Quote and Get to Market Faster

Fully assembled PCBs that work the first time. Ready to ship in as quick as 24 hours.

Whether you’re an aerospace engineer on a tight deadline or a procurement officer looking to simplify your supply chain, Sierra Circuits technicians are an integrated part of the most dependable full-service team in the world.

Ideal for:

- PCB designers and electrical engineers building prototypes or bringing products to market

- Contract manufacturers who need fast, predictable lead times

- Purchasing teams who require pricing and supply-chain transparency

- Tinkerers, hobbyists, and builders who would benefit from the expertise of our in-house CAM engineers

Manufacturing Equipment at Sierra Circuits

Our 70,000 sqft state-of-the-art campus in the heart of Silicon Valley contains the most advanced equipment required for the manufacture and assembly of your PCBs. Whether you’re looking for standard quick turn PCBs or boards with the tightest tolerances, made from exotic metals, there’s a reason Sierra Circuits leads the industry in quality and performance.

Get started with PCB Assembly

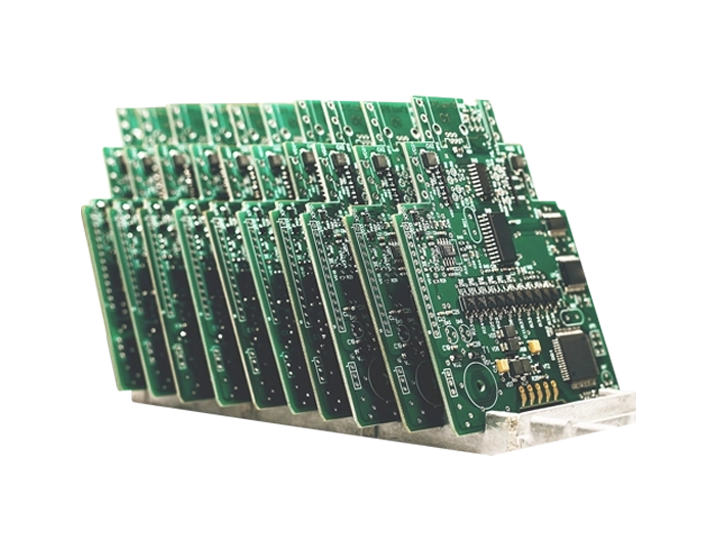

Sierra Circuits is capable of assembling BGA, micro-BGA, QFN and other leadless package parts. Whether you need 1 or 10,000 boards assembled, we make it easy for your project to come to life.

Fabrication, Procurement, & Assembly. PCBs fully assembled in as fast as 5 days.

- Bundled together in an entirely-online process

- Reviewed and tested by Engineers

- DFA & DFM Checks on every order

- Shipped from Silicon Valley in as fast as 5 days

Fabrication. Procurement & Assembly optional. Flexible and transparent for advanced creators.

- Rigid PCBs, built to IPC-6012 Class 2 Specs

- 2 mil (0.002″) trace / space

- DFM Checks on every order

- 24-hour turn-times available

Complex technology, with a dedicated CAM Engineer. Stack-up assistance included.

- Complex PCB requirements

- Mil-Spec & Class 3 with HDI Features

- Blind & Buried Vias

- Flex & Rigid-Flex boards