Seminar: Science of Soldering© by Jim Smith

Jim Smith

Founder of Electronics Manufacturing Sciences, Inc.

Science of Soldering© is coming back!

After attendees rated our first eight Science of Soldering© seminars 5/5, we are excited to announce that expert Jim Smith of Electronics Manufacturing Sciences will return from April 15th to 17th, 2025.

PRICE: $945

MAXIMUM PARTICIPANTS: 12

Date and time:

April 15th to 17th, 2025

8 AM to 1 PM Pacific time

Location: Online via Zoom

You may not think you need this amazing class — but you do

Soldering is the fundamental process in electronics. Virtually every activity determines or is determined by soldering.

Yes, Science of Soldering© will change the life of assembly, repair or prototyping technicians. But the Science of Soldering© lessons are essential even if you never touch a soldering iron. This is critical knowledge for how to make more producible designs, achieve more robust processes, truly manage quality, select and manage suppliers, avoid costly tool and materials purchasing mistakes, and measure the real state of operations. In other words, you need this course if your job involves:

- Manufacturing engineering or management

- Quality engineering or management

- Design engineering or prototyping

- Supplier management

- Operations

- Purchasing

- Assembly or repair

What you’ve been told about soldering is wrong

What you’ve been told about soldering originated half a century ago for reflowing tin-plated leads of large through-hole components protected against damage by mechanical heat sinks. Today’s components and materials aren’t like those. Unlike tin plating which melts during “soldering”, today’s platings don’t melt; additional process steps are needed. Heat sinks won’t fit on today’s tiny leads. Fluxes are vastly more complex and their residues can’t really be removed after soldering. And there’s more.

Processes that worked well in 1980 are disastrous today. But the standards and training curriculums are the same in every aspect that matters. In fact, training and industry “standard” practices cause needlessly high failure rates and large avoidable costs.

Science of Soldering© is unique

Science of Soldering© is not like any other soldering class. It is the only course designed specifically for the challenges of today’s electronics. What is taught is only one difference. How it is taught is just as important. Other courses tell you what to do but not why. Science of Soldering© experiments, demonstrations, process troubleshooting, thorough videos and discussion show why as well as what. This is genuine education, not training based on rules and memorization.

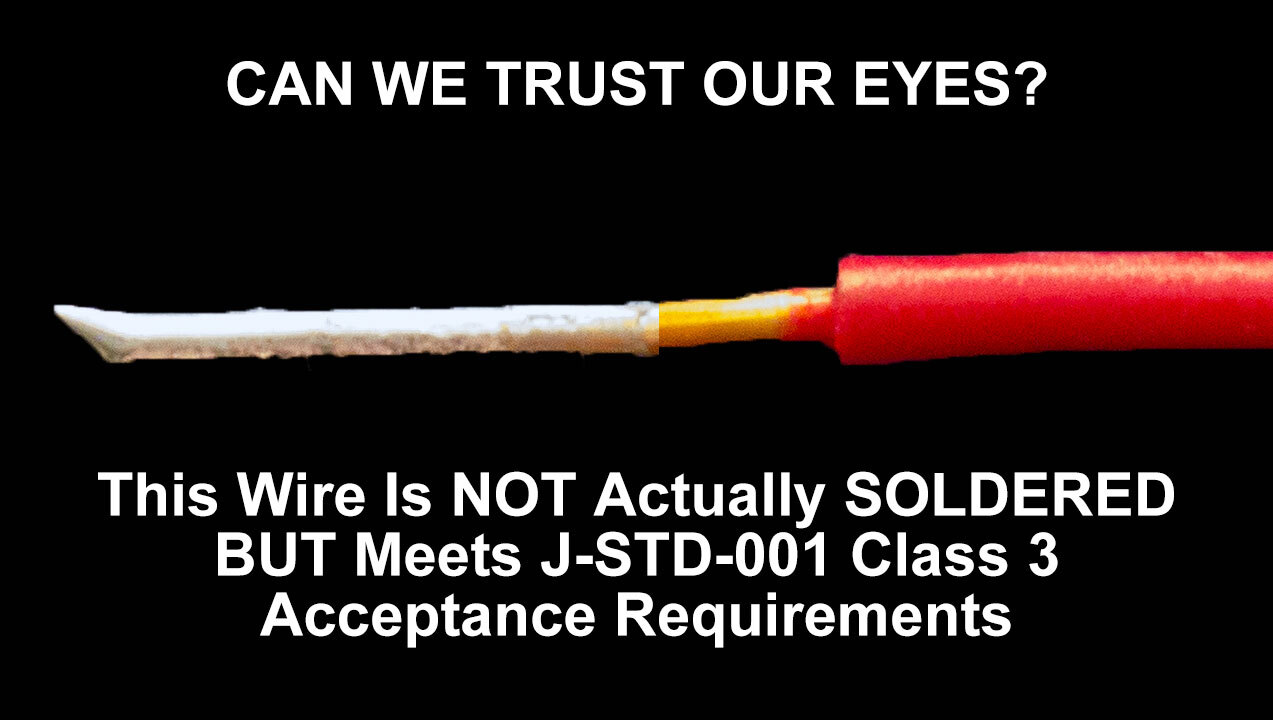

Don’t trust inspection

The most important soldering defects – internal damage to components – can’t be seen. Yes, a cosmetically flawed connection generally indicates a reliability problem. However, beautiful soldering is not necessarily reliable. At soldering iron temperature, solder will stick to oxides and meet the visual acceptance requirements – but the part is not actually soldered. Even worse, the heat needed to make the solder stick degrades electrical bonds inside components. Improperly used soldering irons cause most component failures.

What you will learn in Science of Soldering©

- Soldering is mostly about chemistry

- 7 easy steps that guarantee perfect soldering

- A simple technique for preventing all heat damage (most component failures are caused by overheating components)

- Why cosmetically “perfect” connections may not be reliable (you can’t inspect-in reliability)

- What you must know about flux (and their manufacturers don’t tell you)

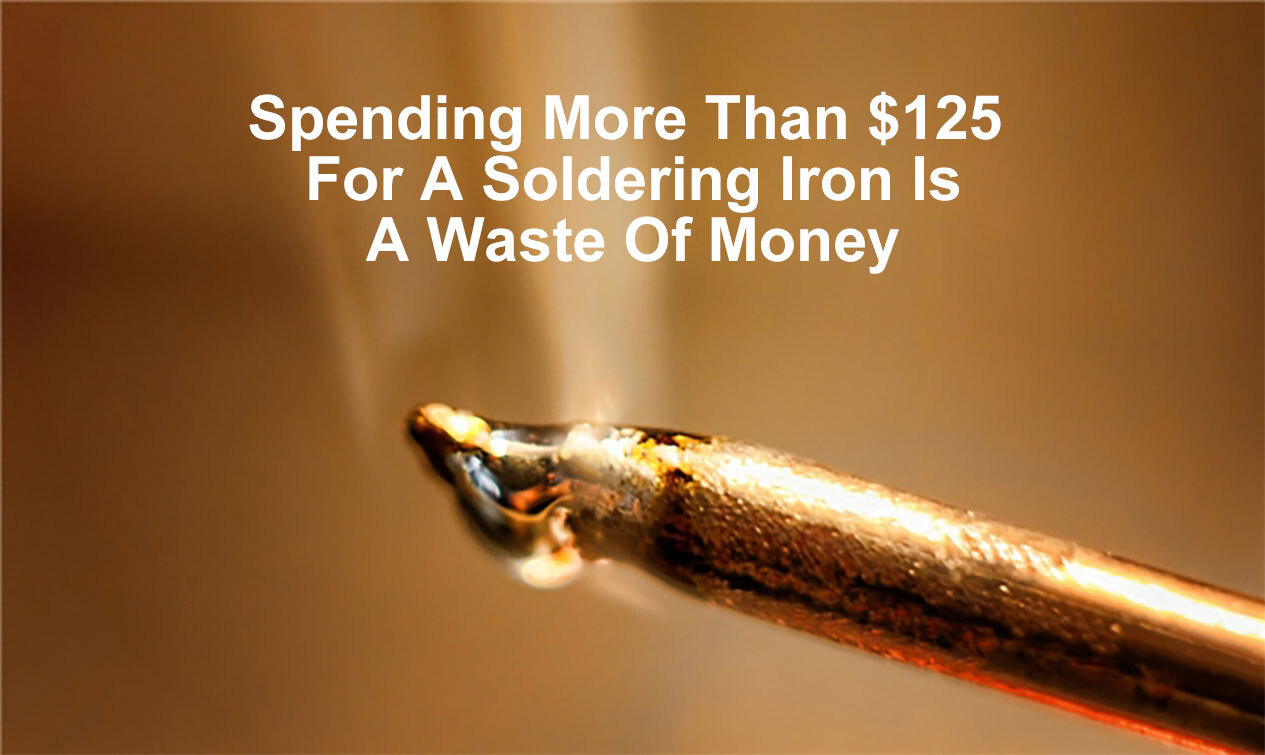

- How to make a $125 soldering iron perform like an $800 iron

- Why “soldering” tin-plated parts is not actually soldering

- A simple, easy way to work with ground planes

- The fast, simple way to solder fine-pitch surface mount components

- How to replace any component quickly and easily without damaging the PCB (and without any special equipment)

- The secret to easy lead-free soldering

- Why flux-cored solder isn’t suited to soldering

- To never trust any lessons from the Internet

- The “industry standards” that are 100% wrong

- And much, much more on how to achieve perfect soldering…

They loved the soldering seminar

William Bruni Jr

Design Engineer, Mitsubishi

“Taking the online soldering seminar with Jim Smith definitely improved my soldering skills. Having basic knowledge of how to solder made it easy for me to get by in my job duties. After taking the seminar, my skills greatly improved. Jim made it easy to pinpoint flaws in my process and helped me refine what I was doing to ensure a better outcome and work product. A small class size and Jim’s extensive knowledge made it a guarantee that each student involved in the seminar got every question answered and consistent results throughout every exercise presented. I would recommend this course to anyone looking to learn more about soldering or brush up on the skills they already possess.”

Yogi Ahuya

Engineering Manager, Advantest

“Jim’s soldering class was very meaningful for me. With 25 years in the PCB industry, I did not have any formal soldering study or training and always felt lacking in my comprehension of this subject. After the class, I had a clearer understanding of the principles, techniques and the language to use when describing the processes of soldering. I recommend this class to every entry level engineer so they start off with the correct information that they can convert into knowledge through experience.”

Willa Hughes

Electrical Engineer, Infinite Biomedical Technologies

“Jim’s class demystified soldering for me – where once I had a mess of contradictory advice, I now have a scientific framework for exactly which soldering processes work and which don’t, and why they do so. Beyond improving my soldering ability, it’s given me the perspective to design better processes.”

Joseph Olson

President, MicroAutomata Corporation

“After 35+ years working as an Electrical Design Engineer with a diversity of companies from start-ups to industry giants, someone has finally shown me how to solder properly. Dr. Smith’s Science of Soldering course completely demystifies the “art’’ of soldering. I’m baffled how something so critical in electronic assembly is so little understood, at least in my experience. An enormously delightful surprise to learn a straightforward and controllable soldering process that yields consistent, predictable, and reliable soldering results.”

Registration will close 15 days before the seminar.

Contact Lucy at lucyi@protoexpress.com for more information.

Please, note that each participant will receive:

• All tools including soldering iron (just put them back in the shipping box and return to Jim after class using the provided prepaid label)

• 78-page Science of Soldering© workbook/reference book with workmanship criteria

• Through-hole and surface mount components and wiring for hands-on experiments and applied exercises

• Assorted solders

• Fluxes

A CERTIFICATE WILL BE SENT AT THE END OF THE SEMINAR.