Copper Foils for High-Speed Digital Applications

Michael Gay

Director of High-Performance Products

Isola

Copper foil for high-speed PCBs

In the realm of copper foil manufacturing for high-speed PCBs, industry standards and processes play a crucial role. This webinar will delve into the intricate details of copper foil production, addressing industry-naming conventions, and the relevance of IPC standards. Explore the latest developments in copper foil technology, with a focus on advancements that impact signal integrity and performance in high-speed digital applications. Uncover the hidden aspects of copper roughness and the intricate trade-offs involved in achieving ultra-smooth surfaces. Delve into the importance of bond treatment for enhanced adhesion and reliability. Join us as industry experts unravel the complexities of copper manufacturing, providing invaluable insights for optimizing your PCB designs.

And try our Material Selector tool.

What you will learn:

- Copper manufacturing process

- Industry naming conventions and IPC

- New copper foil developments

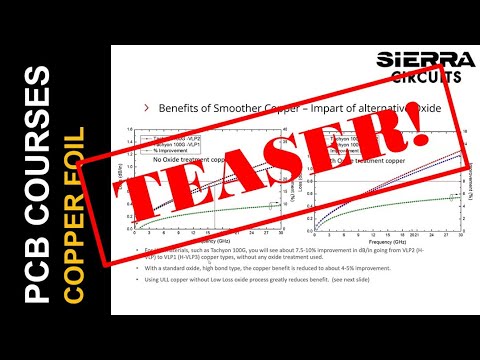

- Copper roughness, the rest of the story

- Ultra smooth copper challenges and trade offs

- Importance of bond treatment

Level: Intermediate

About Michael Gay

Michael J. Gay currently holds the position of Director, High Performance Products with Isola. Michael has been with Isola for 23 years and has 28 years of experience in laminate and PCB manufacturing industries. He has held various positions at Isola which include Technical Sales Manager and Director Emerging Products Asia Pacific Region where his responsibilities ranged from new product introduction, PCB process development and technical support and troubleshooting for Isola customers.

Since returning from his role in Asia, he has worked closely with major industry OEM’s to develop and qualify Isola materials for the next generation of technology. In his current position, he provides product application training, collaborative design support and design reviews for selecting the right material across a wide range of applications including high speed digital, high energy/voltage, CAF resistance and RF/MW.

Michael is also active in various PCB industry organizations where he currently provides technical expertise to industry critical committees and projects.

He received his Bachelor of Science in Mechanical Engineering and Masters of Business Administration from Portland State University.