PCB Schematic Design

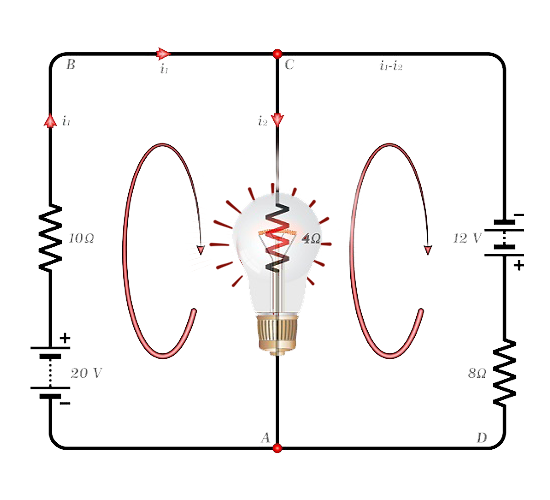

We can create your PCB schematic design from specifications, marked-up schematic sheets, or black diagrams and verbal discussions. We accept schematics in any format (PDF, sketch, etc.) and can convert that into preferred CAD format. As part of our process we validate the BOM.

Start Your Schematic QuoteTHE SERVICES WE PROVIDE

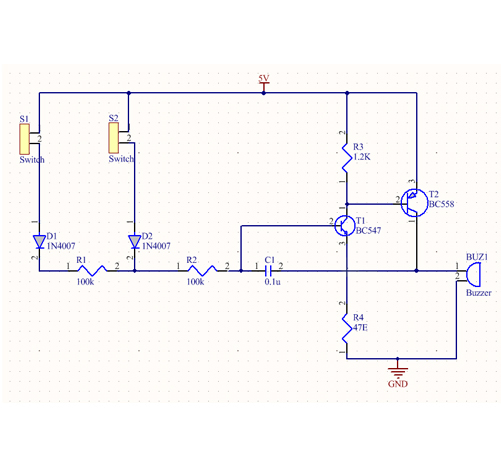

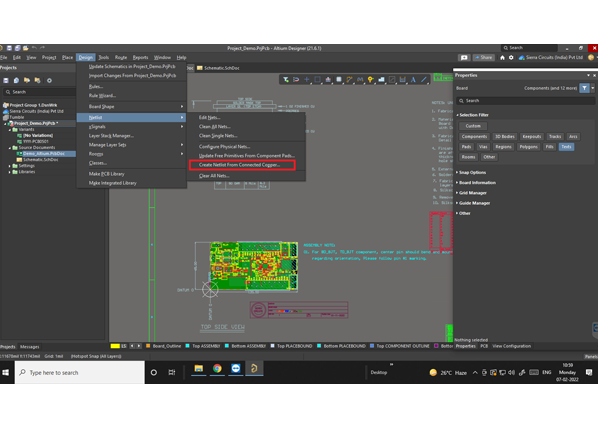

The schematic services include converting a product concept to a schematic or converting a schematic in a PDF format to a schematic in a PCB design tool, such Allegro or Altium Designer.

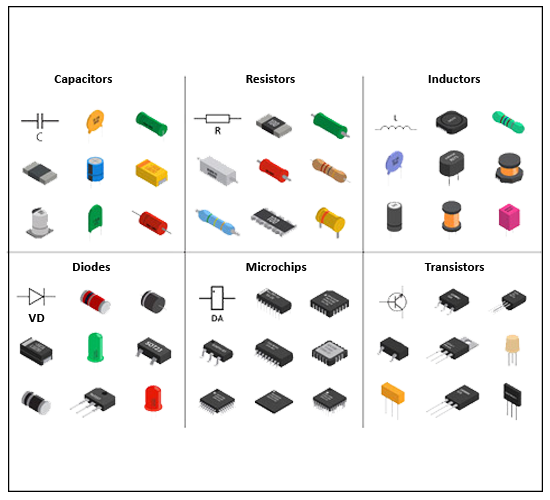

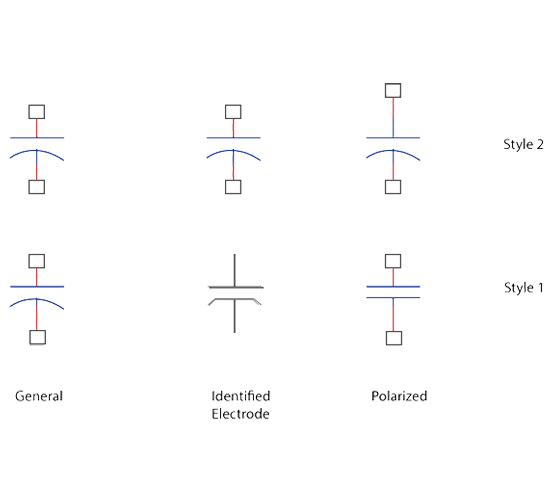

An important part of the symbol generation is quality checks where our team ensures that the symbols match the component datasheet.

THE

PLUS

We offer our services to replace obsolete components in old designs with newer parts.

+

THE TOOLS

OUR DESIGNERS USE

WHY SIERRA

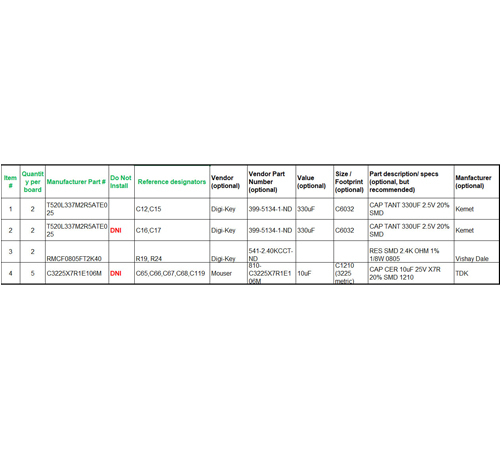

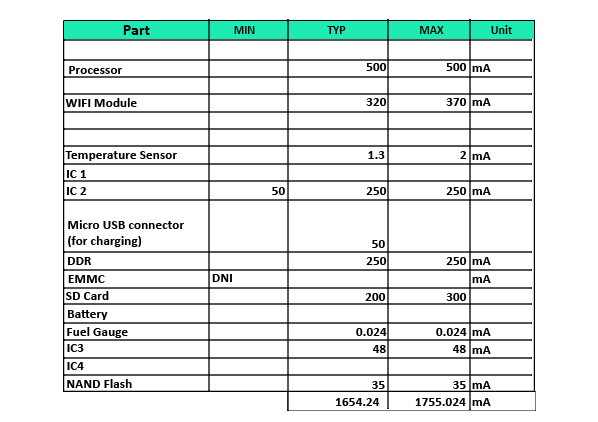

- Our design team performs quality checks at every stage with a thorough netlist check and a BOM validation.

- Since we offer PCB assembly, BOM validation is an in-house service which connects you to different component vendors seamlessly.

Other Ways Sierra Circuits Can Help

We have many resources designed to help you, no matter where you are in your journey to becoming a PCB expert.

PCB Manufacturing& Assembly Processes

Knowing how your boards are manufactured and assembled will help you design boards that are cost-effective and technically robust.

Learn PCB ManufacturingSupport

Need help with your Stackup? Want to find out what our chip stock looks like? Have questions about your order? We're here to help.

Contact SupportShare Project with your Engineers

Access Sierra Circuits Project Access (SPX) Portal. Just like our Customer Portal, SPX is encrypted and fully protected.

Visit the SPX PortalTurn-times as fast as 1 day.

Sierra Circuits can manufacture your PCB and have it expedited to you within 24 hours. Full turnkey boards, with assembly and components in as fast as 5 days. Get an Instant, Itemized Quote

Fabrication, Procurement, & Assembly. PCBs fully assembled in as fast as 5 days.

- Bundled together in an entirely-online process

- Reviewed and tested by Engineers

- DFA & DFM Checks on every order

- Shipped from Silicon Valley in as fast as 5 days

Fabrication. Procurement & Assembly optional. Flexible and transparent for advanced creators.

- Rigid PCBs, built to IPC-6012 Class 2 Specs

- 2 mil (0.002″) trace / space

- DFM Checks on every order

- 24-hour turn-times available

Complex technology, with a dedicated CAM Engineer. Stack-up assistance included.

- Complex PCB requirements

- Mil-Spec & Class 3 with HDI Features

- Blind & Buried Vias

- Flex & Rigid-Flex boards