PCB Design for Signal Integrity

We can perform signal integrity services on any high-speed board designs that we make. We will take care of controlled impedance and crosstalk requirements; we will take care of PCB materials that are suitable to achieve a given set of signal integrity specifications.

Start Your Signal Integrity QuoteOUR SIGNAL INTEGRITY EXPERTISE

Every board undergoes an impedance coupon test during the manufacturing process to ensure that we are meeting your requirements.

To ensure that we have your PCB functionality under control, we use SI simulation tools to determine crosstalk after the initial layout routing.

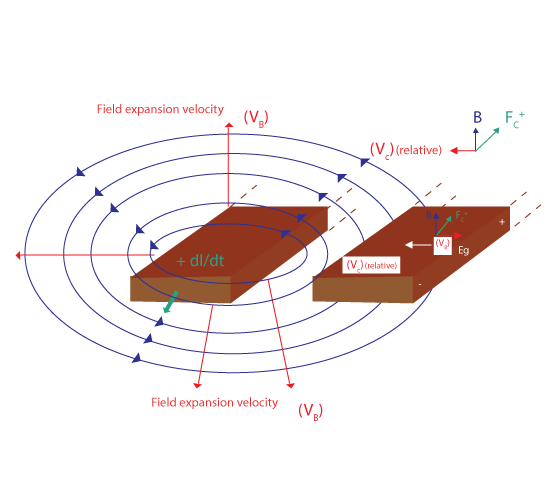

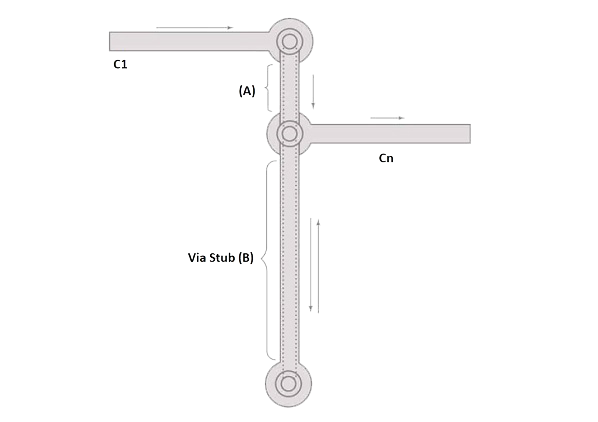

Pull-up or pull-down resistors on high-speed signals are common sources of stubs, which can create reflections that negatively affect signal integrity. If such resistors are required, we route the signals as a daisy chain.

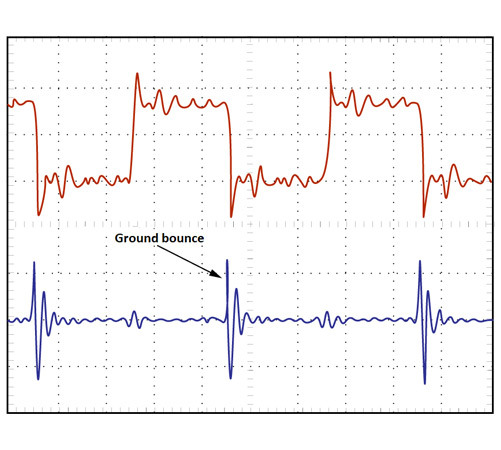

We use state-of-the-art constraint systems, like the ones offered by Cadence and Altium, to help us design out ground bounce.

Selecting the right low-loss and high-speed material is essential to help with signal attenuation, as well as minimizing signal losses via control over the trace geometries.

THE

PLUS

Complex signal integrity requirements demand complex PCB layouts. Our in-house design and electrical engineers bring to the table a deep understanding of rules and techniques to minimize SI issues. We apply our best design practices so you don’t have to worry about costly design iterations.

+

WHY SIERRA

- Sierra Circuits is an expert in building high-frequency PCBs with signal integrity. Impedance control, crosstalk, via stubs, ground bounce, material selection… No one knows better than us how to manage the parameters that will impact the functionality of your circuit right from the design phase.

Other Ways Sierra Circuits Can Help

We have many resources designed to help you, no matter where you are in your journey to becoming a PCB expert.

PCB Manufacturing& Assembly Processes

Knowing how your boards are manufactured and assembled will help you design boards that are cost-effective and technically robust.

Learn PCB ManufacturingSupport

Need help with your Stackup? Want to find out what our chip stock looks like? Have questions about your order? We're here to help.

Contact SupportShare Project with your Engineers

Access Sierra Circuits Project Access (SPX) Portal. Just like our Customer Portal, SPX is encrypted and fully protected.

Visit the SPX PortalTurn-times as fast as 1 day.

Sierra Circuits can manufacture your PCB and have it expedited to you within 24 hours. Full turnkey boards, with assembly and components in as fast as 5 days. Get an Instant, Itemized Quote

Fabrication, Procurement, & Assembly. PCBs fully assembled in as fast as 5 days.

- Bundled together in an entirely-online process

- Reviewed and tested by Engineers

- DFA & DFM Checks on every order

- Shipped from Silicon Valley in as fast as 5 days

Fabrication. Procurement & Assembly optional. Flexible and transparent for advanced creators.

- Rigid PCBs, built to IPC-6012 Class 2 Specs

- 2 mil (0.002″) trace / space

- DFM Checks on every order

- 24-hour turn-times available

Complex technology, with a dedicated CAM Engineer. Stack-up assistance included.

- Complex PCB requirements

- Mil-Spec & Class 3 with HDI Features

- Blind & Buried Vias

- Flex & Rigid-Flex boards