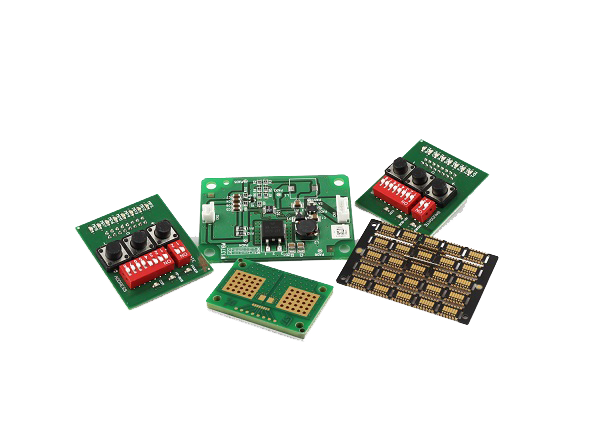

PCB Cost Optimization

We can review an existing product or design and propose methods for cost reduction. In many cases, layer reduction can be achieved by using smaller geometries for conductors and vias and the use of laser-drilled microvias.

Start Your Cost Optimization QuoteFACTORS THAT AFFECT THE COST OF PCB FABRICATION

A few factors can increase the cost of PCB manufacturing. Our design engineering team will take a closer look at your project and identify the areas of improvement.

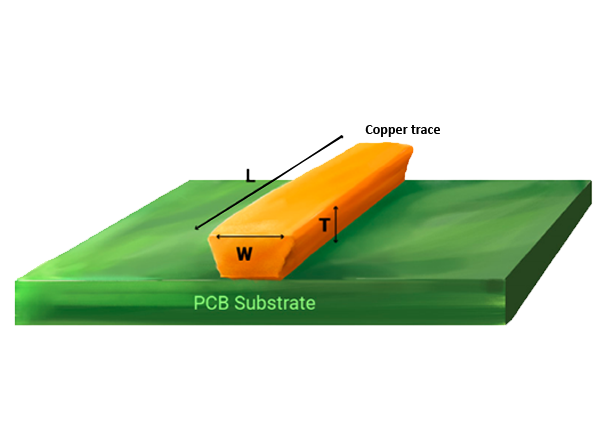

From a cost optimization standpoint, your traces and spaces should be greater than 4.25 mils.

THE

PLUS

Our design engineers are experts in reducing our customers' PCB fab spend. They follow a set of best practices that only a manufacturer knows. Plus, they work closely with our manufacturing and assembly teams to make sure there are no unnecessary costs embedded in your project.

+

WHY SIERRA

- Since we have considerable experience in dealing with PCB materials, fabrication and assembly processes, as well as components, we know which areas of your design can be improved to drive the price down. Plus, due to the close interaction between our layout and manufacturing teams, we can ensure a quality board free of rework costs.

Other Ways Sierra Circuits Can Help

We have many resources designed to help you, no matter where you are in your journey to becoming a PCB expert.

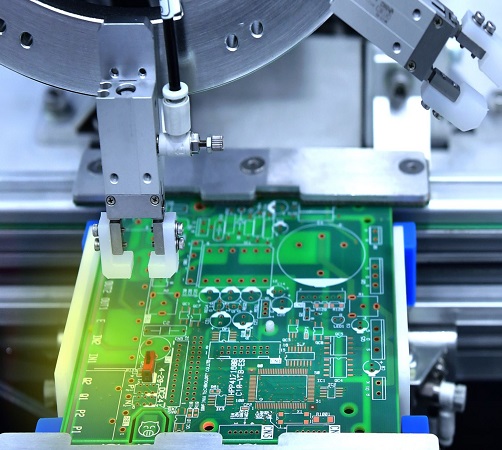

PCB Manufacturing& Assembly Processes

Knowing how your boards are manufactured and assembled will help you design boards that are cost-effective and technically robust.

Learn PCB ManufacturingSupport

Need help with your Stackup? Want to find out what our chip stock looks like? Have questions about your order? We're here to help.

Contact SupportShare Project with your Engineers

Access Sierra Circuits Project Access (SPX) Portal. Just like our Customer Portal, SPX is encrypted and fully protected.

Visit the SPX PortalTurn-times as fast as 1 day.

Sierra Circuits can manufacture your PCB and have it expedited to you within 24 hours. Full turnkey boards, with assembly and components in as fast as 5 days. Get an Instant, Itemized Quote

Fabrication, Procurement, & Assembly. PCBs fully assembled in as fast as 5 days.

- Bundled together in an entirely-online process

- Reviewed and tested by Engineers

- DFA & DFM Checks on every order

- Shipped from Silicon Valley in as fast as 5 days

Fabrication. Procurement & Assembly optional. Flexible and transparent for advanced creators.

- Rigid PCBs, built to IPC-6012 Class 2 Specs

- 2 mil (0.002″) trace / space

- DFM Checks on every order

- 24-hour turn-times available

Complex technology, with a dedicated CAM Engineer. Stack-up assistance included.

- Complex PCB requirements

- Mil-Spec & Class 3 with HDI Features

- Blind & Buried Vias

- Flex & Rigid-Flex boards