Webinar: Via-in-Pad and Microvia Design Techniques for HDI Boards

REGISTER NOW

November 5th, 2025 | 10 AM PT

COST: FREE

-

6

Days

-

17

Hours

-

7

Minutes

-

50

Seconds

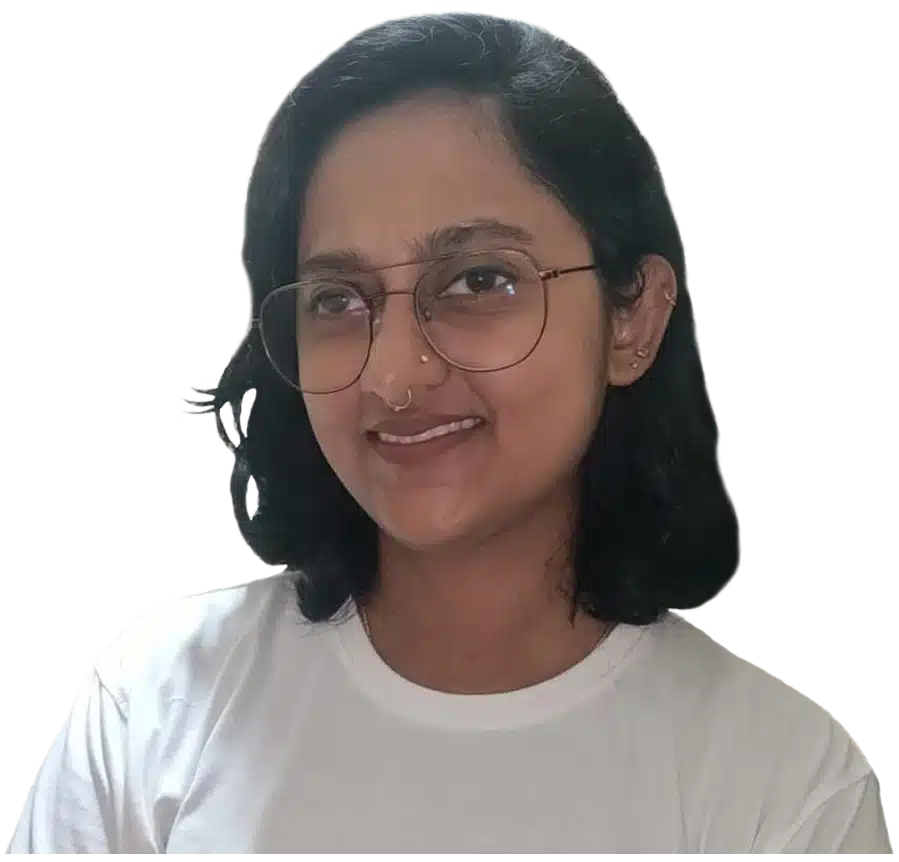

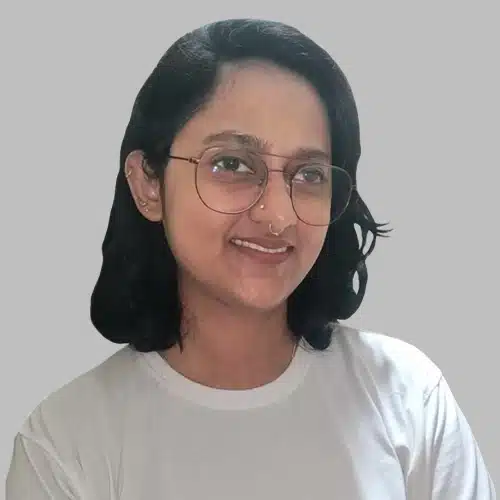

Vandana CC

Engineering Project Coordinator at Sierra Circuits

This webinar will be hosted on Zoom.

Following this event, you will receive:

-

Recording

-

Slides

Webinar abstract:

As electronics continue to get smaller and faster, the toughest challenge you face in PCB layout is executing high-density routing without compromising signal integrity. Fine-pitch BGAs, dense interconnects, and higher data rates leave little room for traditional via structures. That’s where via-in-pad and microvia designs come in.

In this webinar, you’ll learn how to design and implement via-in-pad and microvia structures effectively. You will gain practical insights on selecting materials, defining via fill types, and applying DFM guidelines for high-density circuits.

Via-in-pad and microvia design strategies to achieve mechanical reliability

Via-in-pad structures become essential when working with fine-pitch BGAs (0.5 mm). Here, placing vias directly beneath BGA pads saves space and minimizes stub length.

For fine-pitch BGA fanouts, use filled and capped vias to prevent solder wicking during reflow. Maintain a 0.75:1 aspect ratio for microvias and 8-10 mil of capture pads for adequate plating. Avoid stacking more than two microvias, as higher stacking might lead to failures due to CTE mismatches.

Material selection has a direct impact on manufacturability. Choose low Dk/Df laminates like Isola I-Tera MT40, Panasonic Megtron 6, or Rogers 4000 series to avoid signal distortion. Maintain at least 3 mil dielectric thickness, and consult your fabricator about their laser drill, copper thickness, and planarization capabilities.

REGISTER NOW

When you go for cap plating, always mention “filled and capped vias required” in your fab notes. Additionally, specify ENIG or ENEPIG surface finishes with 15-25 µin gold and 100-150 µin nickel for these kinds of designs. You can also request an X-ray and cross-section inspection report in your design documentation.

For better reliability, maintain at least 8 mil drill-to-copper clearance. Early DFM evaluation prevents rework and ensures optimum yield.

With the growing demand for compact and high-reliability PCBs, grasping via-in-pad and microvia design techniques has become an essential skill.

Join us to gain confidence in HDI designs with real-world DFM insights.

Webinar agenda:

- Via-in-pad design rules for fine-pitch BGA

- Design considerations for microvias

- Picking suitable HDI substrates

- Epoxy vs. copper via filling

- Fab notes for microvias and via-in-pads

- DFM guidelines

About Vandana CC

With a strong foundation in physics, Vandana CC brings a deep technical understanding to her work in PCB design and electronics manufacturing. She holds a Master’s in Physics and has experience teaching before transitioning into research at the Indian Institute of Science.

At Sierra Circuits, Vandana has played a key role in R&D projects, contributing to the development of engineering tools and calculators, technical content creation, and customer demos. Currently, she focuses on project coordination, ensuring seamless collaboration both within the team and with external partners. Her expertise bridges the gap between technical innovation and practical application, making her an integral part of Sierra Circuits’ engineering efforts.