Design Guidelines

Download our design guides

for better PCB designing and manufacturing

These are some of the design guides designers and engineers download the most:

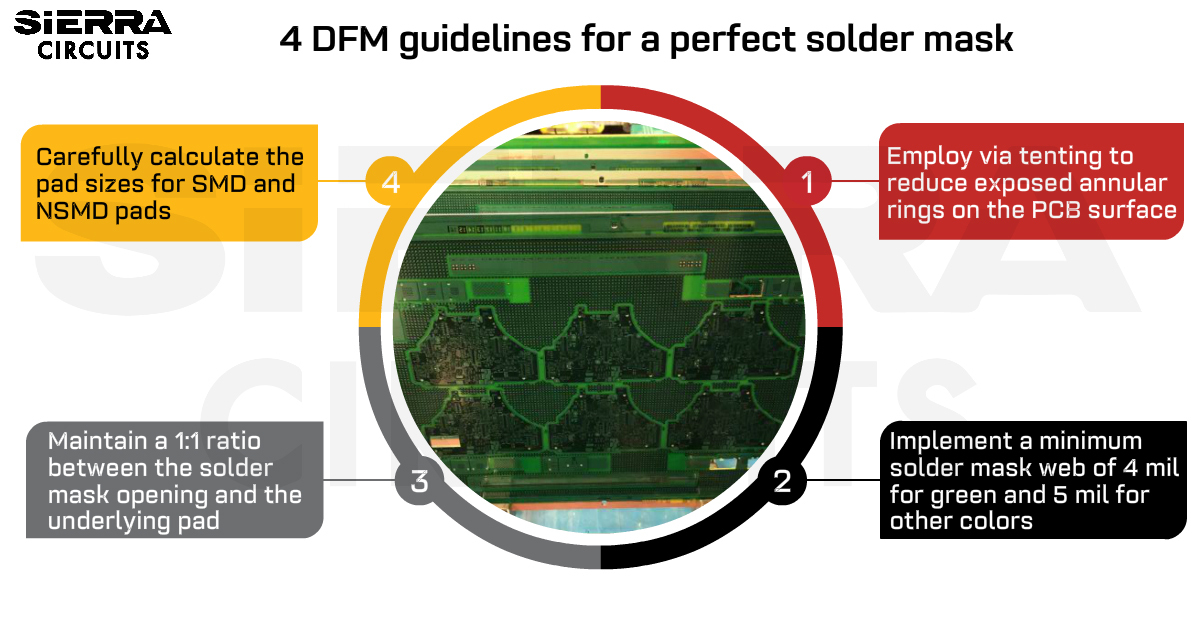

- DFM Handbook

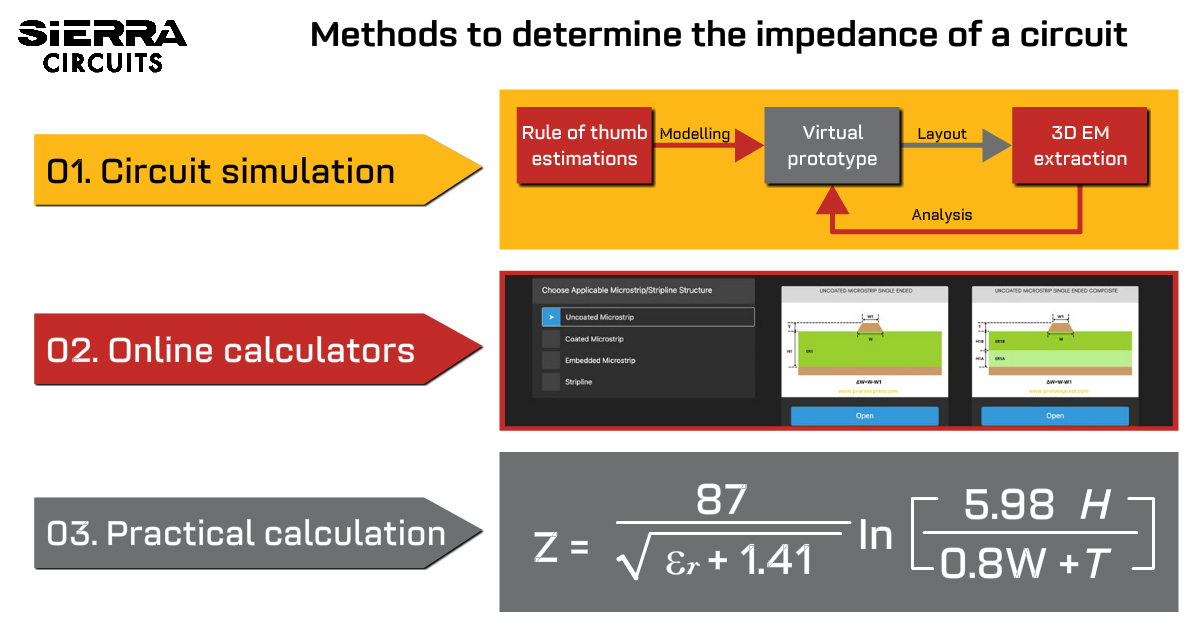

- Controlled Impedance Design Guide

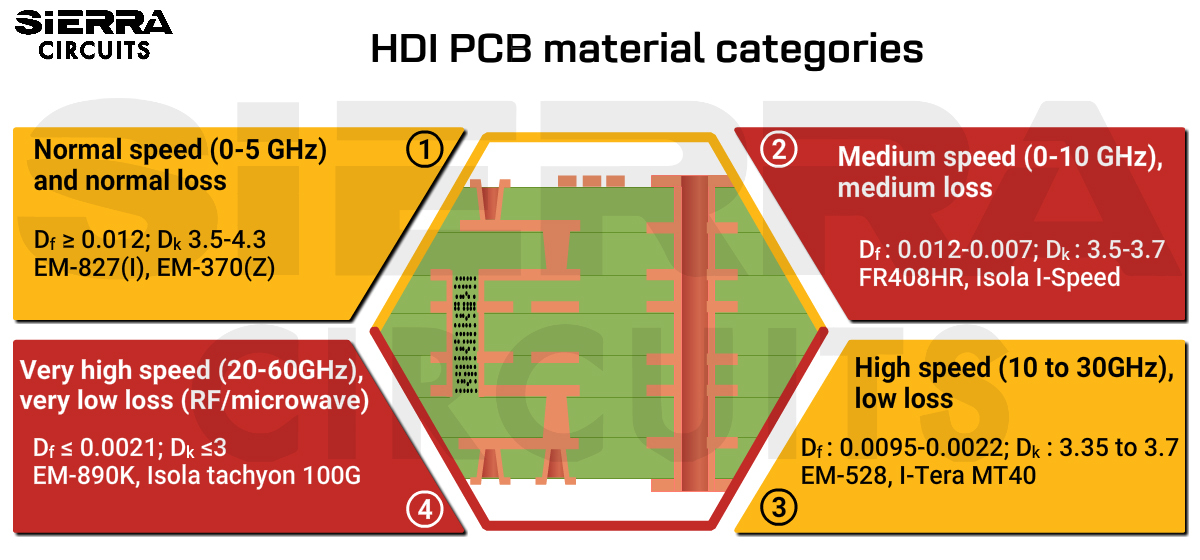

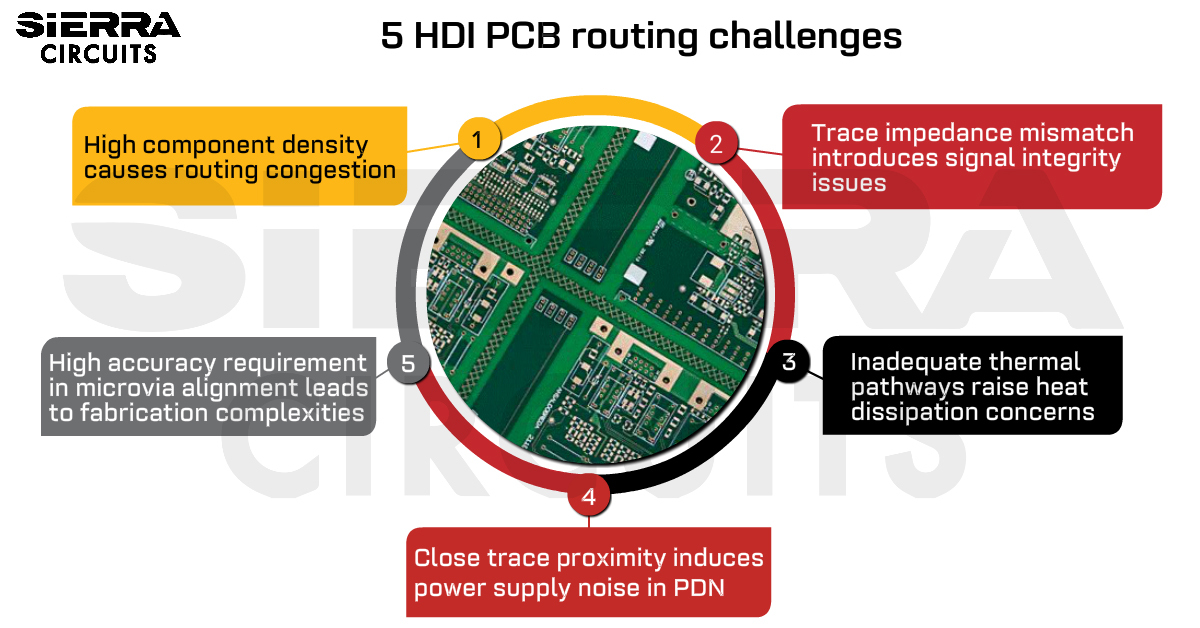

- HDI Design Guide

- PCB Transmission Line eBook

- High-Speed PCB Design Guide

- PCB Material Design Guide

- DFA Handbook

Fabrication, Procurement, & Assembly. PCBs fully assembled in as fast as 5 days.

- Bundled together in an entirely-online process

- Reviewed and tested by Engineers

- DFA & DFM Checks on every order

- Shipped from Silicon Valley in as fast as 5 days

Fabrication. Procurement & Assembly optional. Flexible and transparent for advanced creators.

- Rigid PCBs, built to IPC-6012 Class 2 Specs

- 2 mil (0.002″) trace / space

- DFM Checks on every order

- 24-hour turn-times available

Complex technology, with a dedicated CAM Engineer. Stack-up assistance included.

- Complex PCB requirements

- Mil-Spec & Class 3 with HDI Features

- Blind & Buried Vias

- Flex & Rigid-Flex boards